Ultrasint® TPU01

Thermoplastic Polyurethane Powder for HP Jet Fusion Printers

Ultrasint® TPU01 is a multi-purpose thermoplastic polyurethane (TPU) powder, ideal for the production of parts requiring shock absorption, energy return or flexibility.

Material Details

This highly processable multi-purpose material is explicitly designed for HP’s 5200 series Multi Jet Fusion printers. Ultrasint® TPU01 offers strong, flexible and durable part performance, combined with an excellent surface quality and level of detail. Typical applications include sports protection equipment, footwear, orthopaedic models, car interior components and various industrial tools like pipes and grippers.

Ultrasint® TPU01 opens unlimited design possibilities: it is extremely easy to print, has a very high process stability, and one of the highest throughputs for flexible materials in the 3D printing market. These unique characteristics make it a perfect fit for serial production with HP Multi Jet Fusion printers.

Sustainability Check

Benefits at a Glance

- High elasticity, rebound and resistance to fatigue

- Excellent surface quality and level of detail

- High process stability and throughput

- Easy finishing incl. smoothing and Ultracur3D Coating

- BASF supports in design optimization with Ultrasim

- High recycling rate of 80%

- Colour: grey

Example Applications

- Sports protection equipment

- Footwear

- Orthopaedic models

- Car interior components

- Tools, grippers and pipes

Material Properties

- Hardness shore: 88-90 A

- Tensile strength: 9 MPa

- Young’s modulus: 85 MPa

- Elongation at break: 280 %

- Charpy Impact (notched, 23°): no break

- Rebound resilience: 63 %

Print your Parts with Forward AM Materials!

Discover our comprehensive services and solutions here

Use Cases and Whitepaper of Ultrasint® TPU01

Motorbike Saddle

Whether it’s a bicycle or motorbike, the saddle is the paramount comfort factor of every two-wheeler. Bikers know that a comfortable saddle is vital…

Automotive – Ultrasint® TPU for Car Interior Applications

For the automotive industry, Additive Manufacturing enables completely new application concepts, lighter parts as well as time and cost savings for…

Prosthetic Socket

Today amputees requiring prosthetic limbs have to put up with often uncomfortable, poorly fitting sockets. A collaboration between ProsFit and…

Improving Ultrasint® TPU01 part properties by PostPro® vapour smoothing

With Additive Manufacturing, it can be challenging to produce parts with professional-grade surface finishes, making post-processing an essential…

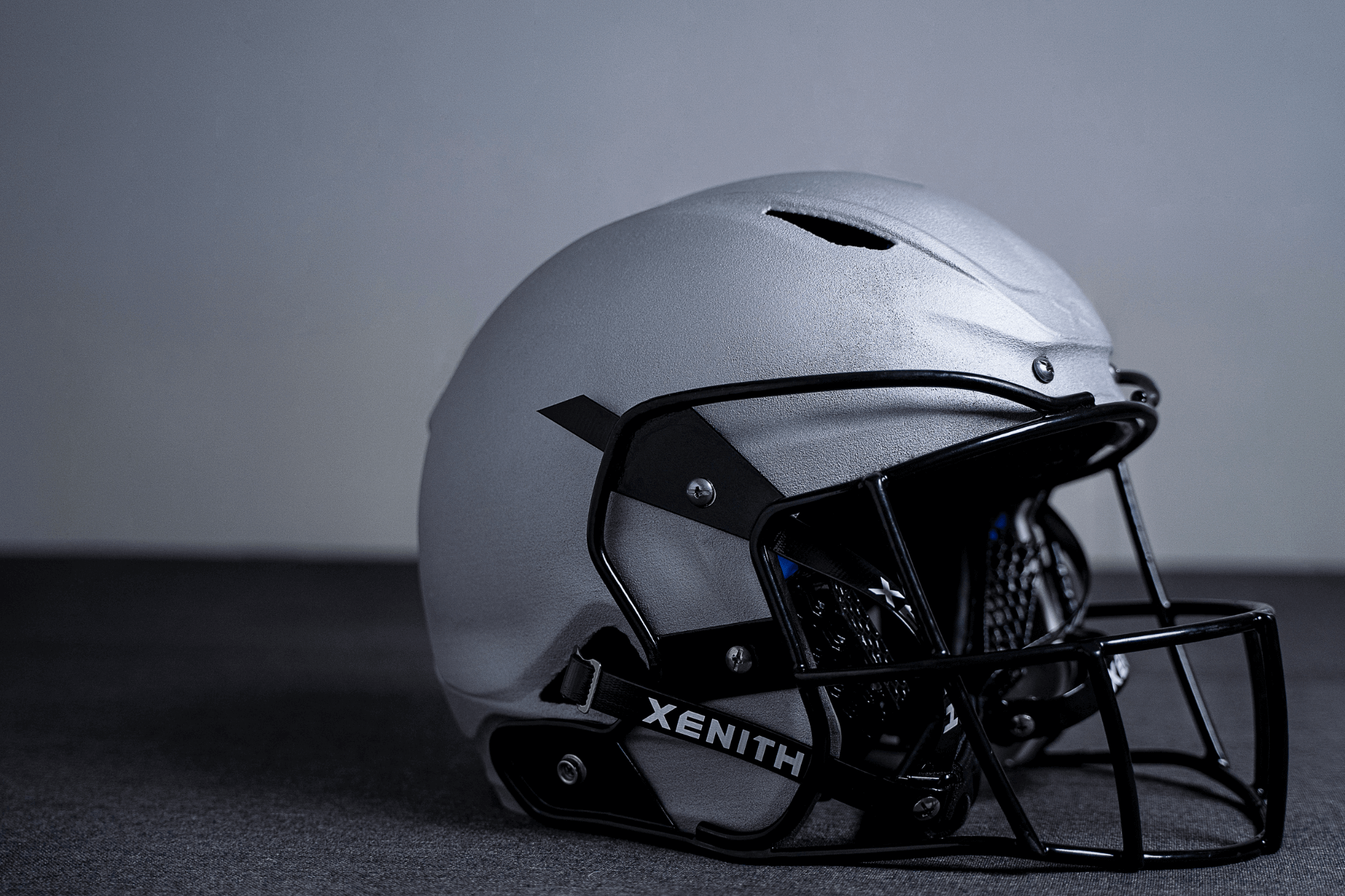

Protective Helmets

In baseball, hockey, football and all other sports, head trauma through collision is an omnipresent risk for all athletes. And it doesn’t stop with…

Cycling Enthusiasts Find Increased Comfort and Improved Performance Through Customized Bike Saddles

Innovative material and enhanced design provides superior performance and exceptional durability for industrial filtration screens

How Additive Manufacturing Enables More Personalized Healthcare with Adaptiiv

By leveraging Additive Manufacturing, Forward AM’s powder Ultrasint® TPU01, and HP Inc. (HP) Multi Jet Fusion (MJF) printing technology, Adaptiiv On…

BASF Forward AM and DyeMansion: Optimizing Post-Processing for Ultrasint® TPU01

With BASF Forward AM’s extensive materials knowledge and DyeMansions vast post-processing expertise, we are able to optimize the post-processing…

Reaching new Summits with the first 3D printed Climbing Shoe

Climbing sports has experienced a tremendous surge in popularity over the past years. No matter if amateur or pro athlete, if bouldering or rock…

Blazing the Comfort Trail

Enhanced backpack carrying experience through 3D printed lattice comfort elements at reduced assembly time and cost.

How Forward AM and Erpro Deliver the Decisive Edge on the Racetrack

For many of us, motorcycling is nothing but pure passion. Looking at a motorcycle, the seat is the very part where rider and bike ideally become one…

Unlocking Limitless Creativity for the Furniture Industry

Since thousands of years, humans have used chairs to increase comfort. The clunky wooden structures our hardy ancestors had to endure progressively…

Protective Lattice Layer for Cobots

In today’s modern factories around the globe, many production steps are automated and carried out by robots. Humans sharing a workspace and…

Protective Pads

When doing sports, rather than worry about the risk of injury we want to focus on our performance and the enjoyment it gives us. With rising consumer…

The #vanlife of the Future – Realized by BASF for HYMER

Global demand for premium Recreational Vehicles (RVs) has been rising continually for several years now and is currently at an all-time high. More…

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrasint® TPU Product Range materials

Ultrasint® TPU 88A

Thermoplastic Polyurethane Powder for durable parts with excellent flexibility

Benefits at a Glance

- High elasticity, rebound and resistance to fatigue

- Excellent surface quality and level of detail