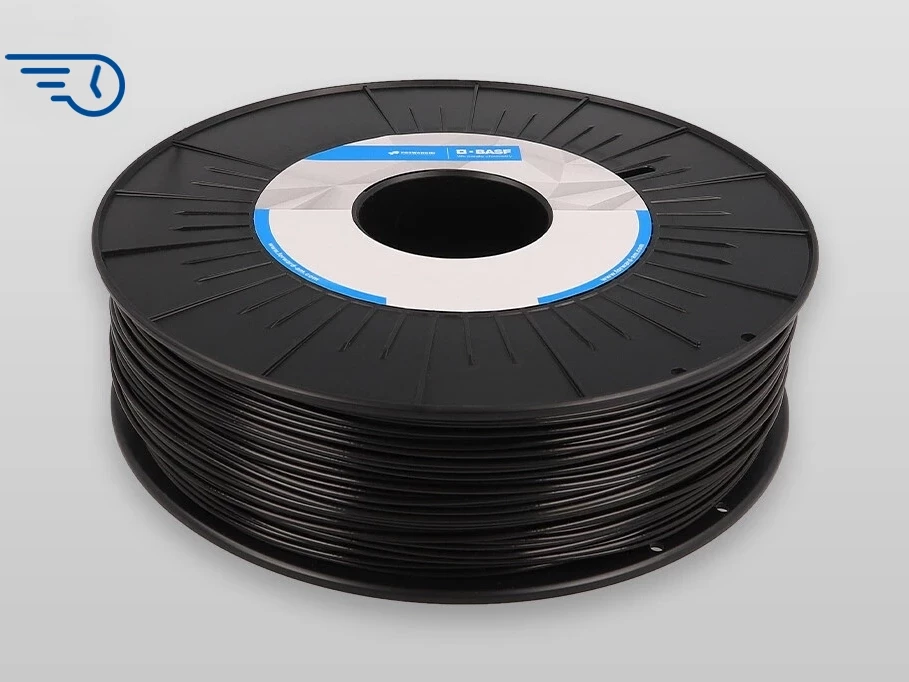

Ultrafuse® PP

Ultrafuse PP is high-performance thermoplastic with low density, high elasticity and high resistance to fatigue.

The mechanical properties make it an ideal material for 3D-printing applications which have to endure high stress or strain. The filament has high chemical resistance and a high isolation value. PP is one of the most used materials in the world, due to its versatility and ability to engineer lightweight tough parts.

Material Details

- Technical Data Sheet: EN, FR, ES, DE, ZH

- Safety Data Sheet: EN, other languages

- Printing Profiles

Sustainability Check

Recycled Packaging

Generally recyclable

Benefits at a Glance

- Tough and strong

- Fatigue resistant

- Chemical resistant

- Light weight (low density)

- Biocompatible

Example Applications

- Chemical contact

- Prototyping

Material Properties

- Tensile Strength (MPa): 9.0 (ZX), 15.5 (XY)

- Flexural Modulus (MPa): 380 (ZX), 494 (XZ), 575 (XY)

- Elongation at Break: 5.4 % (ZX), 118.6 % (XY)

- Impact Strength Izod notched (kJ/m2): 2.3 (ZX), 10.6 (XZ), 5.3 (XY)

- Impact Strength Izod unnotched (kJ/m2): 11.6 (ZX), 37.6 (XZ), 37.7 (XY)

- HDT @ 0.45 MPa: 54 oC

Printing Guidelines*

- Nozzle Temperature: 220-240 °C

- Build Chamber Temperature: -

- Bed Temperature: 60 - 80 °C

- Bed Material: PP tape or PP adhesive

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 20-300 mm / s**

* The product data is provided in good faith and represents typical properties based on our current knowledge and experience; these data are not to be construed as specification limits or mini- mum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application.

** To achieve faster printing speeds, it may be necessary to raise the nozzle temperature. The highest speed mentioned has been determined through our latest tests, ensuring optimal surface quality with a 0.4mm nozzle and 0.2mm layer height. Please note that as printing technology and equipment evolve, we anticipate the possibility of achieving even faster speeds in the future.

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® Standard Filaments

Ultrafuse® rPET

Sustainability Meets High Performance with Ultrafuse® rPET

Benefits at a Glance

- Sustainable alternative to PET

- Easy to print Great end results

Ultrafuse® PLA

PLA, Poly-Lactic-Acid is one of the most used materials for 3D printing and is available in a wide range of colors.

Benefits at a Glance

- Large color range

- Easy to print

Ultrafuse® PET

Ultrafuse PET is made from a premium PET and prints as easily as PLA but is much stronger.

Benefits at a Glance

- Watertight prints possible

- Easy to print like PLA

- Premium food-approved raw material

- Good layer adhesion

- Easy to handle

Ultrafuse® ABS

Strong, flexible, and has a high heat resistance. ABS is a preferred plastic for engineers and professional applications.

Benefits at a Glance

- Long life span

- Very tough