Ultracur3D® RG 1100

Rigid Resin with Superior Stiffness and Temperature Resistance

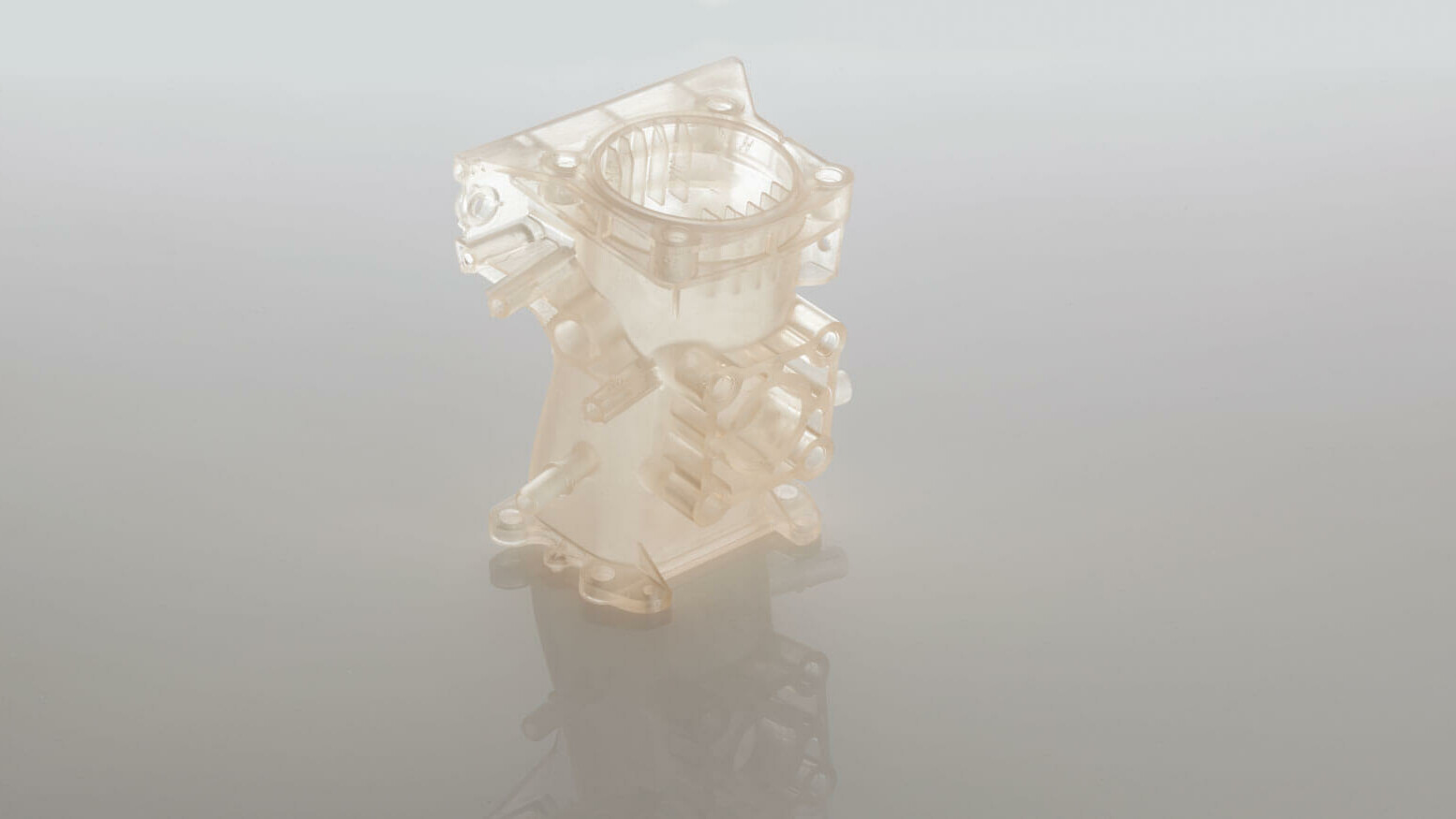

Ultracur3D® RG 1100 by Forward AM is a high-strength polyurethane-based engineering grade resin with mechanical properties comparable to widely spread injection molding grades used in automotive or other demanding industries. Due to its high heat deflection temperature (HDT 116°C), its good chemical resistance and long-term UV-stability this material is perfectly suitable for applications such as automotive connectors, demanding engineering parts, exterior covers, brackets and housings.

Benefits at a Glance

- Very high stiffness

- Impressive all-round temperature resistance

- Very high chemical resistance and low water uptake

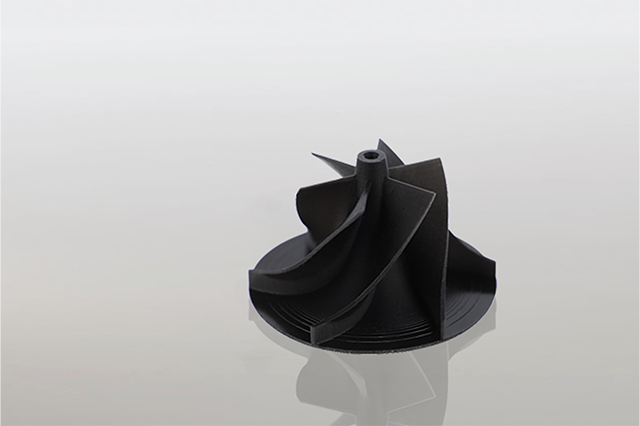

Example Applications

- Automotive connectors

- Demanding engineering parts

- Exterior covers

- Brackets and housings

Material Properties

- Young’s modulus: 3080 MPa

- Tensile strength: 70 MPa

- Heat deflection temperature: 116 °C

- Water absorption (24h): 0.32 %

Next Steps

Reference Links and Documents

Printing Workflows

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultracur3D® RG Product Range Materials

Ultracur3D® RG 35

Rigid resin with optimum combination of strength, stiffness and temperature resistance

Benefits at a Glance

- Very high stiffness and high temperature resistance

- High accuracy and low shrinkage

- Low water uptake

- Easy to polish

Ultracur3D® RG 50

Water-washable rigid resin for printing parts with the highest accuracy

Benefits at a Glance

- Very high accuracy and low shrinkage

- Parts can be washed with water, no chemicals needed

- Very low viscosity, allowing easy handling and fast printing

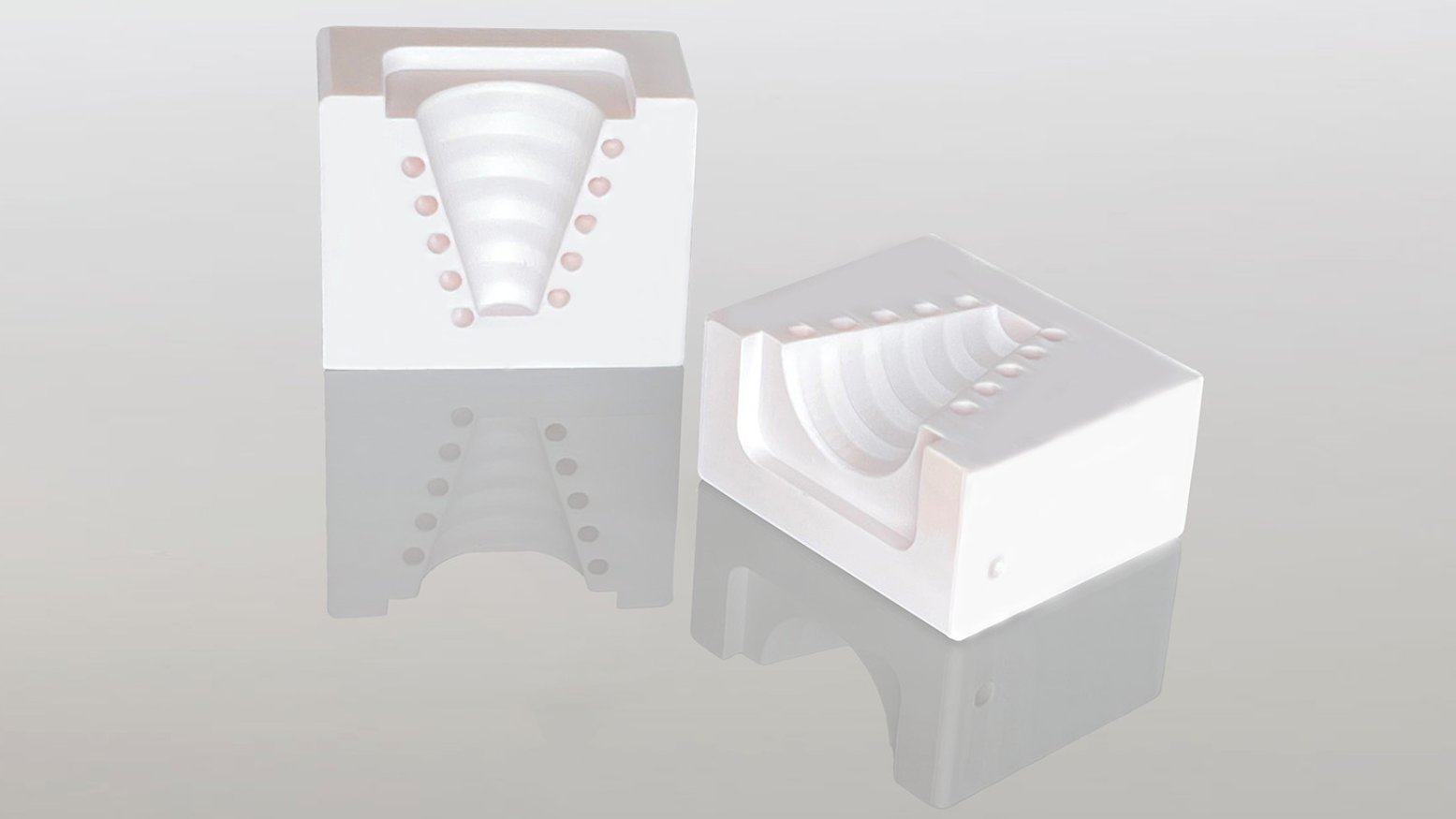

Ultracur3D® RG 3280

Ceramic-filled resin with exceptionally high stiffness and temperature resistance

Benefits at a Glance

- Superior stiffness

- Superior temperature performance

- Very fast and easy to print

- High suspension stability

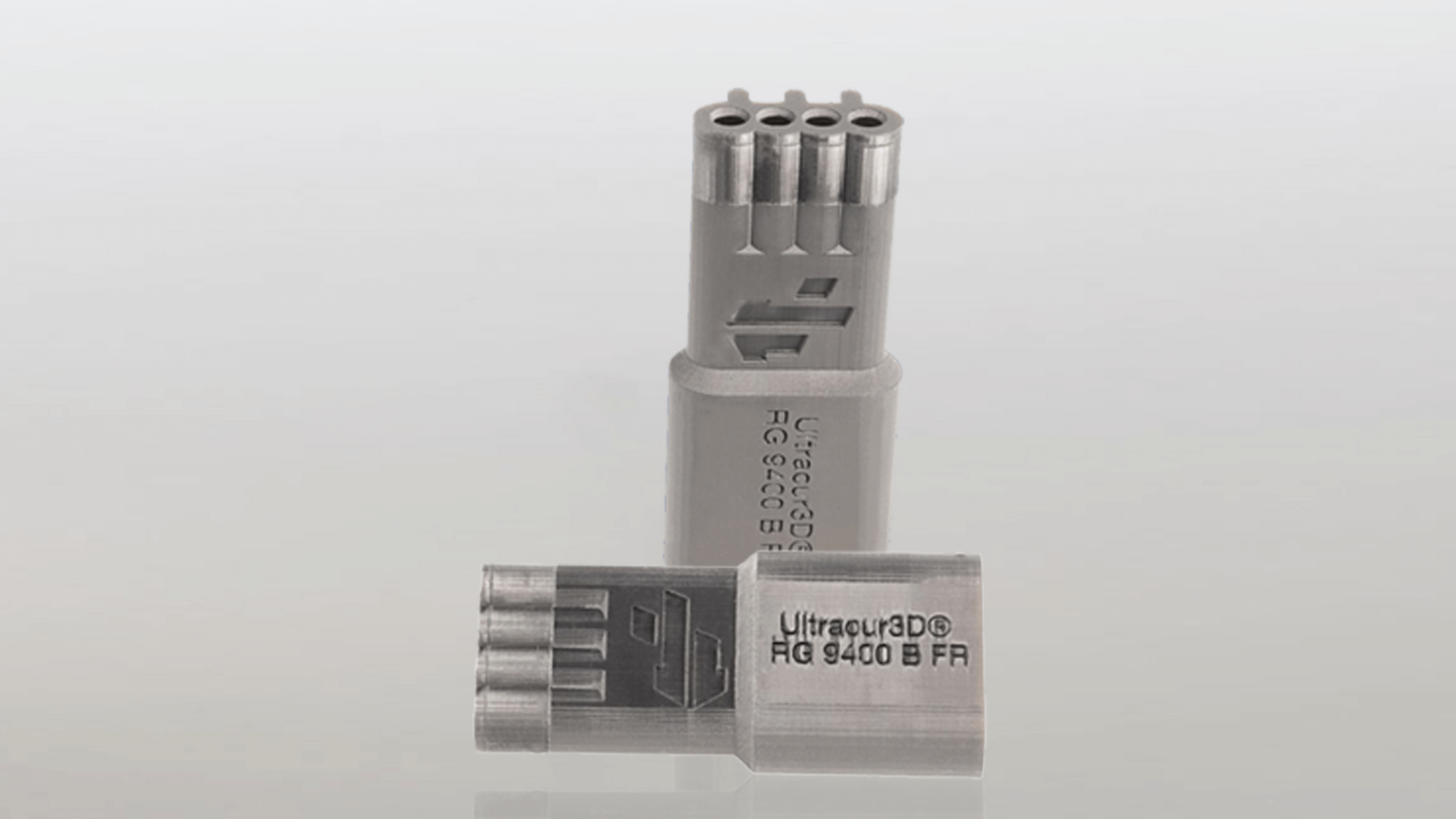

Ultracur3D® RG 9400 B FR

Flame-retardant resin with UL 94 V-0 rating and superior HDT

Benefits at a Glance

- Flame-retardant (UL 94 V-0 at 3mm)

- Very high temperature resistance (HDT B >250°C)

- Easy to print and process, no heated printer required