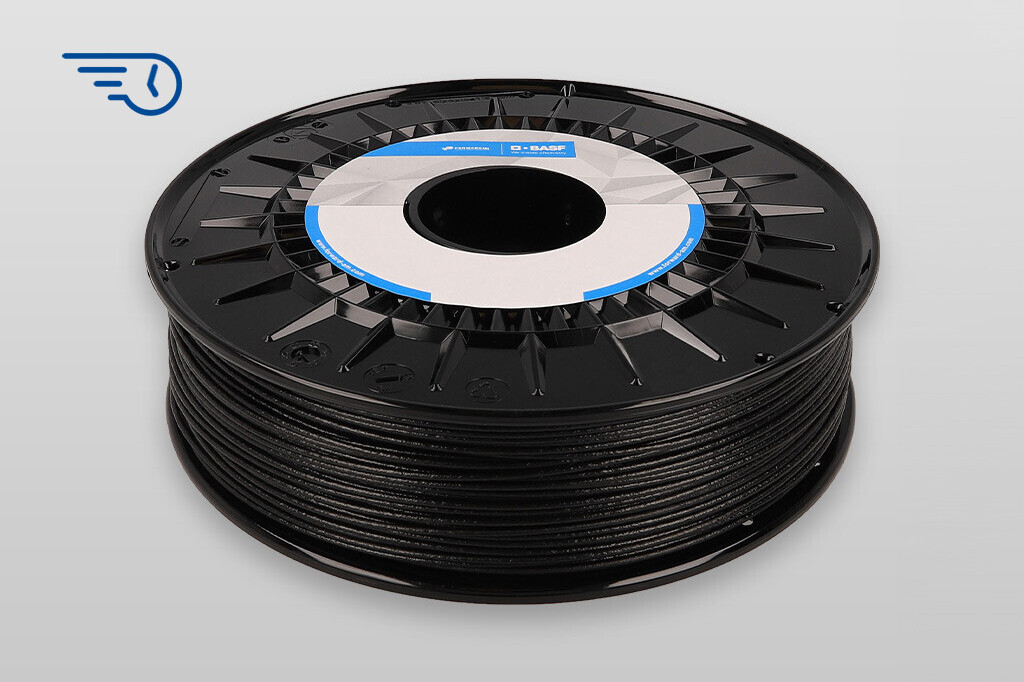

Ultrafuse® PC GF30

Perfect solutions for transportation industry applications

Ultrafuse® PC GF30 filament for 3D printing is a 30% glass fiber filled material designed to be compatible with any standard Fused Filament Fabrication 3D printer (1.75 and 2.85 mm diameters available).

Material Details

- Product Leaflat

- Technical Data Sheet: EN, FR, ES, DE, ZH

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

Ultrafuse® PC GF30 is a unique compound of PC with 30% glass fibers, specially designed for FFF printing. With its high heat deflection temperature and good dimensional stability, Ultrafuse® PC GF30 is the right material to use in an industrial environment where good temperature resistance and high strength is needed.

Its UL94 V0 rating makes PC GF30 the perfect solution for applications in transportation industry that require flame retardancy. The resistance to UV light exposure and its low moisture uptake makes Ultrafuse® PC GF30 highly suitable for interior and exterior applications.

Sustainability Check

Recycled Packaging

Generally recyclable

Benefits at a Glance

- Flame retardancy V0 according to UL 94 (@1.5mm and 3.0mm)

- Resistance to UV light exposure

- Good temperature resistance

- High stiffness and strength

- Good heat deflection temperature

- High dimensional stability

- Very low moisture absorption

- Railway classification according to EN 45545-2

Example Applications

- Automotive / transportation

- Functional prototyping

- Electronics

Material Properties

- Tensile Strength (MPa): 36,1 (XY), 11,2 (ZX)

- Elongation at Break (%): 2,4 (XY) , 1,1 (ZX)

- Flexural Modulus (MPa): 2690 (XY) , 3450 (XZ) , 934 (ZX)

- Impact Strength Charpy unnotched (kJ/m2): 17,1 (XY) , 18,9 (XZ) , 3,7 (ZX)

- Impact Strength Izod unnotched (kJ/m2): 13,9 (XY) , 17,8 (XZ) , 3,4 (ZX)

- HDT @ 0,45 MPa: 134 °C

Printing Guidelines*

- Nozzle Temperature: 280 - 330 °C

- Build Chamber Temperature: -

- Bed Temperature: 80 - 100 °C

- Bed Material: Perforated plate, DimaFix or Magigoo PC glue*

- Nozzle Diameter: ≥ 0.6 mm

- Print Speed: 30 - 60 m / s

*The product data is provided in good faith and represents typical properties based on our current knowledge and experience; these data are not to be construed as specification limits or mini- mum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application.

Next Steps

Standard Printing Profiles

Select your printer below to access your printer profile. Click here to learn more about how to work with printer profiles.

High Speed Printing Profiles

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® Reinforced Filaments

Ultrafuse® PP GF30

Ultrafuse® PP GF30 contains 30% of special glass fibers that are designed for filament making and 3D printing.

Benefits at a Glance

- Excellent chemical resistance

- Low density

Ultrafuse® PET CF15

Ultrafuse® PET CF15 Combines Easy Processability and very Low Moisture Uptake with Excellent Strength and Rigidity – at an Affordable Cost

Benefits at a Glance

- Strong, rigid components Easy to process

- Very low moisture absorption

Ultrafuse® PAHT CF15

Ultrafuse® PAHT CF15 is a high-performance 3D printing filament that opens up new application areas in FFF printing.

Benefits at a Glance

- Higher chemical resistance than most PA grades

- High-temperature resistance up to 150 °C

Ultrafuse® PA6 GF30

Ultrafuse PA6 GF30 is a polyamide 6, reinforced with 30% glass fiber content.

Benefits at a Glance

- Very high stiffness and strength (up to +250% compare to ABS)

- High wear resistance