Ultrafuse® PPSU

Welcome to the World of High Temperature Stable Applications!

Ultrafuse® PPSU was specially developed for FFF printing based on BASF ́s advanced Ultrason® materials. The Ultrason® resins are amorphous thermoplastics derived from polyethersulfone (PESU), polysulfone (PSU) and poly- phenylsulfone (PPSU) and ensure very high thermal resistance.

Material Details

- Technical Data Sheet: EN, FR, ES, DE, ZH

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

With its wide spectrum of material performance advantages, Ultrafuse® PPSU can be successfully used in applications where other plastics, e.g. polyamide, polycarbonate, polyoxymethylene and polyalkylene terephthalates, fail to meet the performance specifications. With its inherent flame-retardant properties, it is an especially suitable material for the aerospace industry.

Sustainability Check

Recycled Packaging

Generally recyclable

Benefits at a Glance

- Inherently flame retardant

- Flame retardancy V0 according UL 94 (@1.5mm and 3.0mm)

- Short-term temperature resistance up to 220 °C

- Resistant to long-term service temperatures up to 180 °C

- High dimensional stability

- Creep strength at high temperatures

- Resistant to hot water and coolants

- Oil-resistant, even at temperatures up to 170 °C

- Fuel and fluorine resistant

- Railway classification according to EN 45545-2

Example Applications

- Suitable for autoclaving processes

- Aerospace industry

- All applications exposed to high temperatures

Material Properties

- Tensile Strength (MPa): 49.0 (ZX), 74.5 (XY)

- Flexural Modulus (MPa): 1700 (ZX), 1910 (XZ), 1940 (XY)

- Elongation at Break: 2.9 % (ZX), 7.3 % (XY)

- Impact Strength Izod notched (kJ/m2): 5.3 (ZX), 15.8 (XZ), 13.7 (XY)

- Impact Strength Izod unnotched (kJ/m2): 21.0 (ZX), no break (XZ), no break (XY)

- HDT @ 0.45 MPa: 215 oC

Printing Guidelines*

- Nozzle Temperature: 390-410 °C

- Build Chamber Temperature: 170-210 °C

- Bed Temperature: 220 °C

- Bed Material: BASF fiber reinforced build sheet

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 25-50 mm / s

*The product data is provided in good faith and represents typical properties based on our current knowledge and experience; these data are not to be construed as specification limits or minimum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application.

Use Cases and Whitepaper of Ultrafuse® PPSU

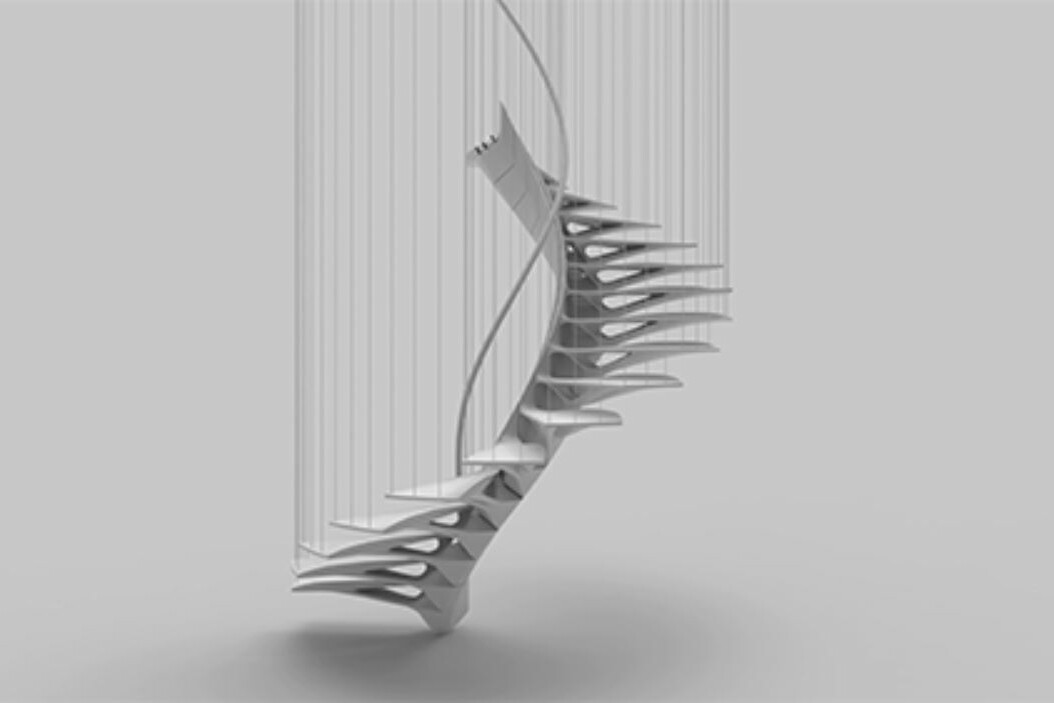

Concrete Formwork

Architecture is the maximum expression of contemporary aesthetics and zeitgeist, showcasing the conceptual and technical aspirations of the age.…

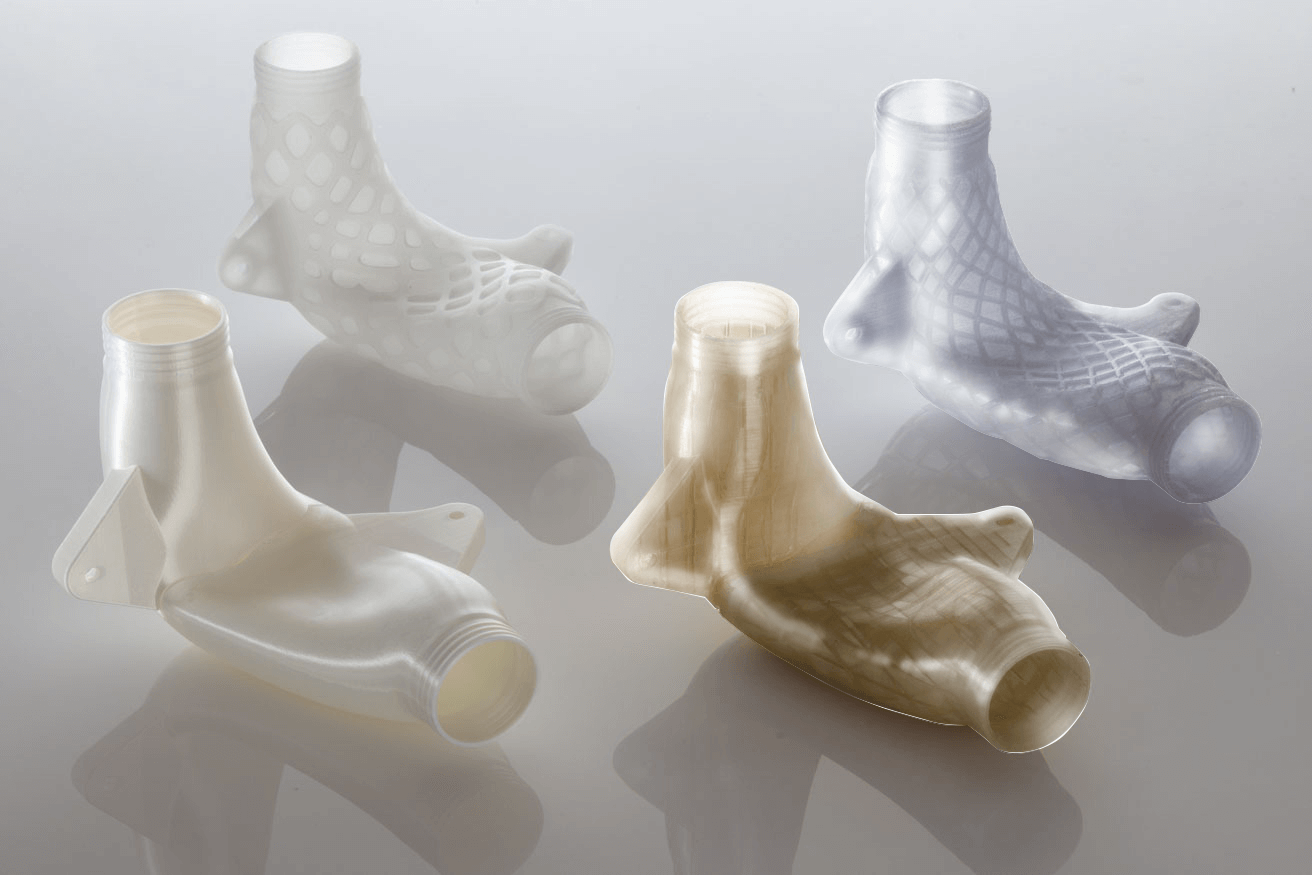

Airflow Pipe

In the aerospace industry, every single gram counts. As a matter of fact, the #1 way for aerospace companies to save money is by reducing weight.…

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® High Temperature Filaments

Nothing found.