Depowdering

Get the essentials right

Depowdering of a PBF part is crucial in every instance, irrespective of the end-use application or potential subsequent post-processing steps.

No strings attached!

Depowdering

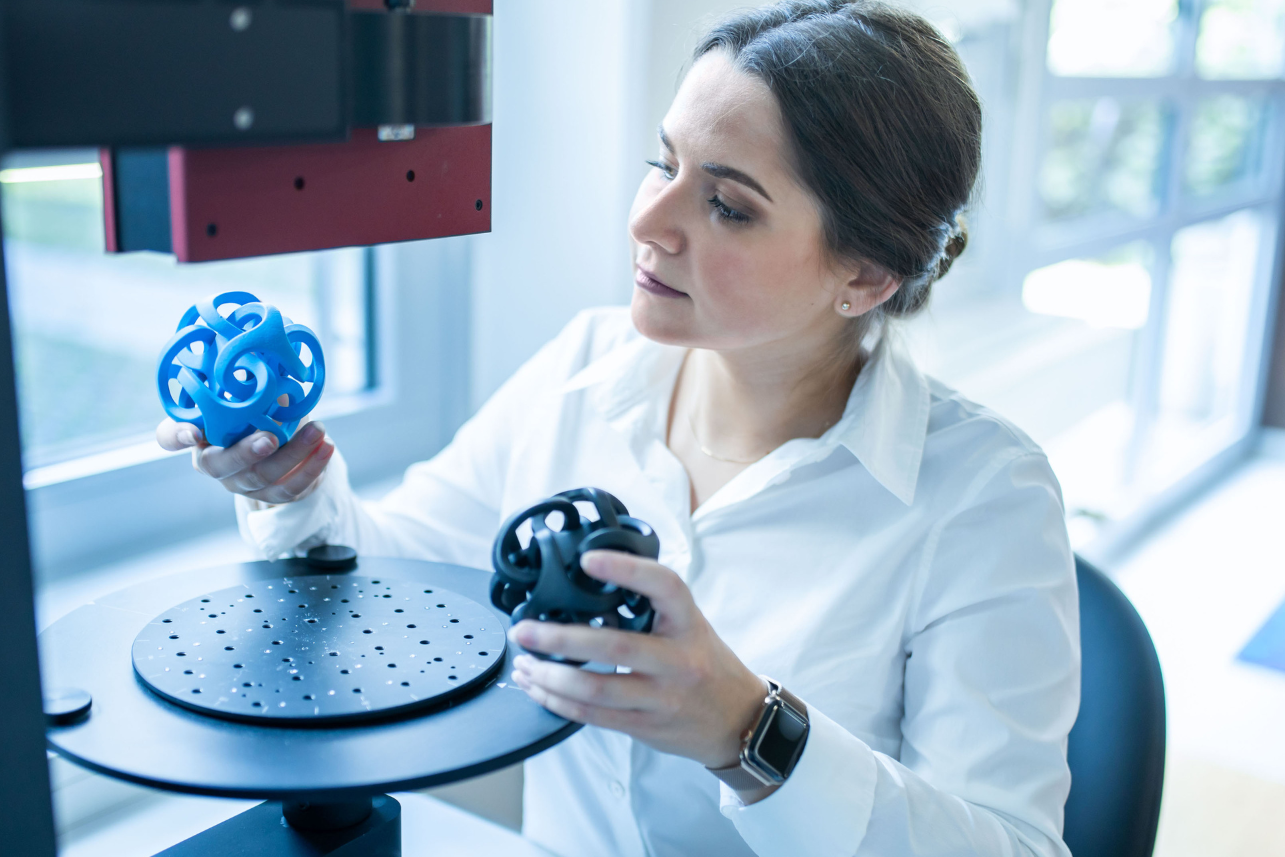

The first step in post-processing PBF parts is depowdering. It is a crucial and necessary step for all PBF parts, whether the part remains as-printed or goes through subsequent post-processing steps such as smoothing, coating, and dyeing. But, despite its importance, its impact on the end-use part is often underestimated and still faces challenges that must be addressed.

What can affect the depowdering of a 3D printed part?

Therefore, to truly optimize the depowdering of a PBF part, materials and process expertise are critical. This is why the collaboration between BASF Forward AM and our partners is essential and effective.

Whitepaper

BASF Forward AM and DyeMansion: Optimizing Post-Processing for Ultrasint® TPU01

BASF Forward AM’s Ultrasint® TPU01 is an ideal material to use with PBF due to its high flexibility and durability for applications across all industries. But the benefits of flexible materials come with challenges when it comes to post-processing.

Discover other Services

Ultracur3D® Coatings

Discover the possibilities of coating your part with our Ultracur3D® Coat F+.

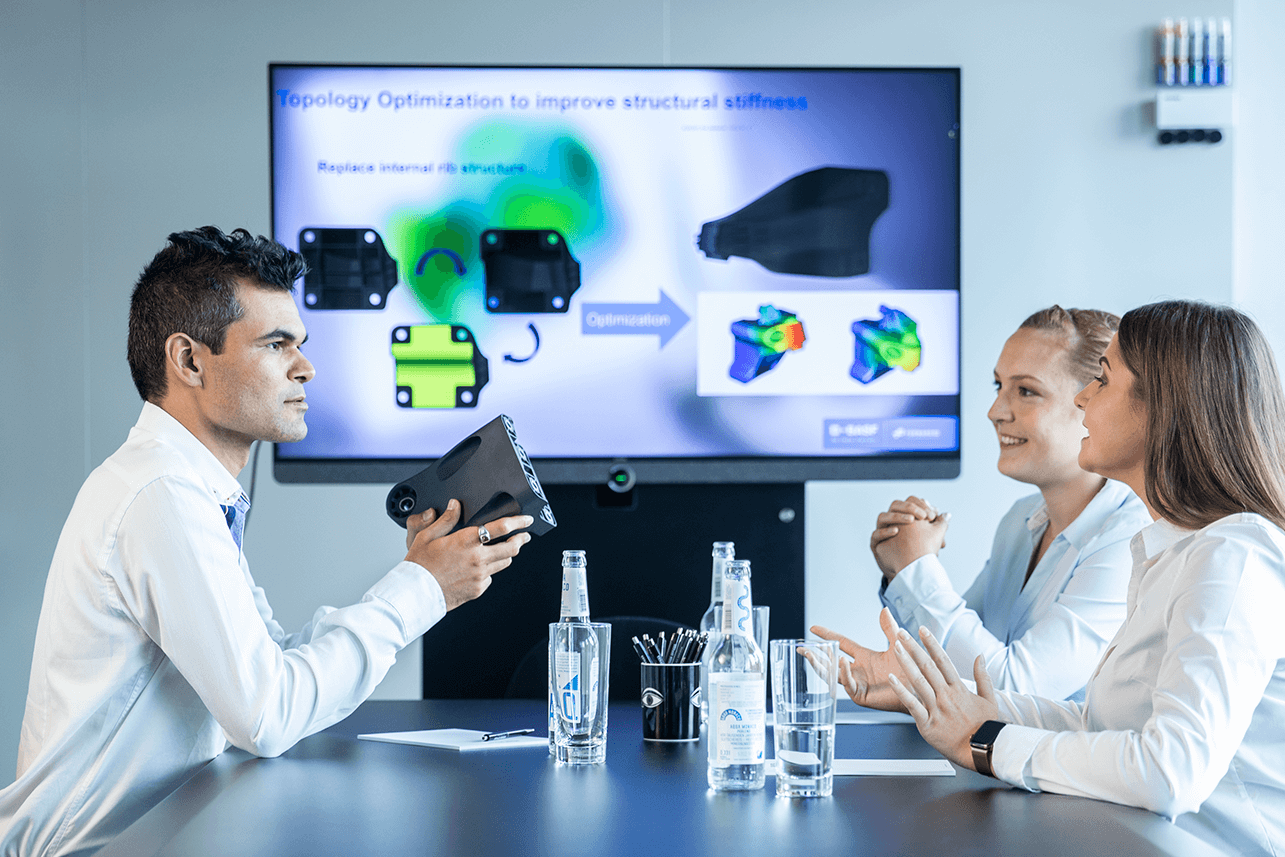

Ultrasim® 3D Consulting

Discover how simulation of part behavior and Design for AM increases the success rate of your 3D printed part.

Solve it with us

Do you have questions about our lattice offerings or other services? Get in touch! No strings attached!