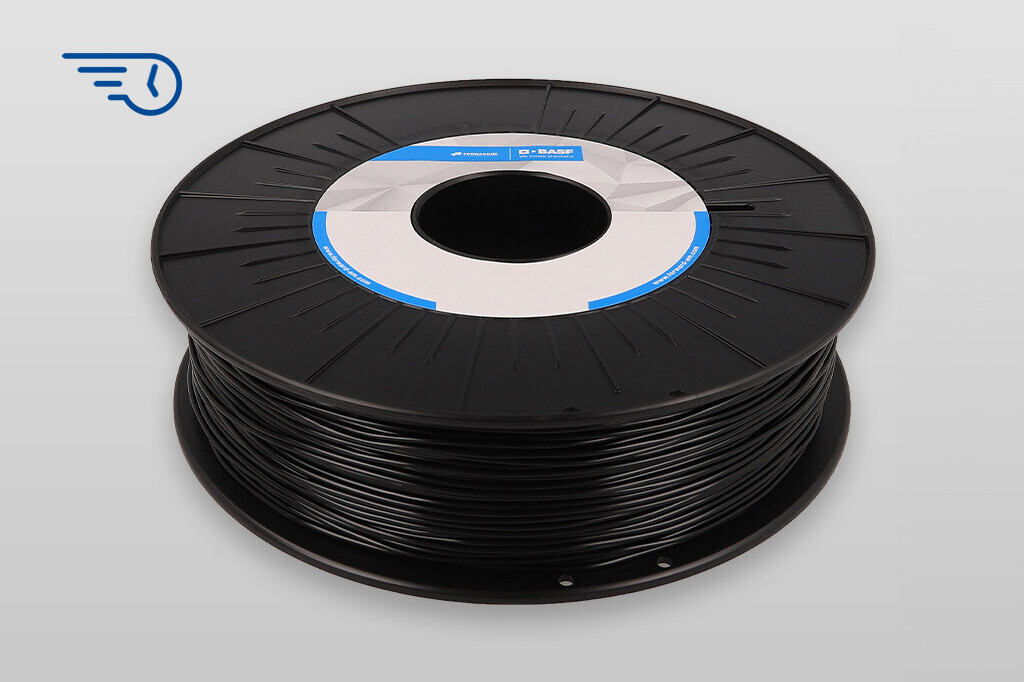

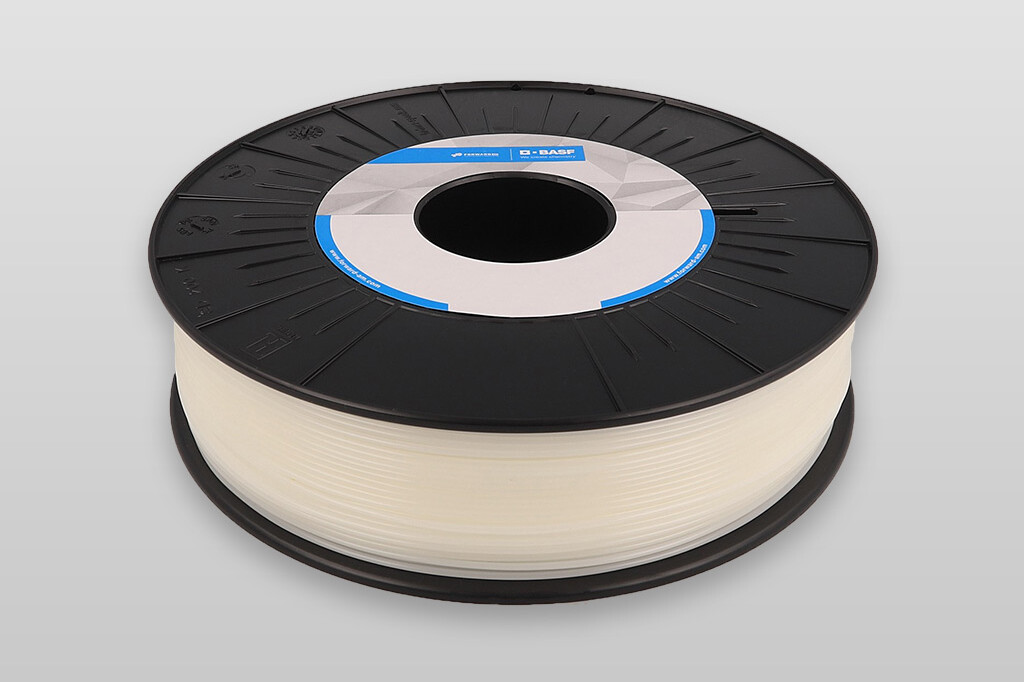

Ultrafuse® TPU 85A

First Flexible BASF Filament Based on Elastollan®

Ultrafuse® TPU 85A was specially developed for FFF printing and is an advanced filament based on BASF ́s Elastollan® materials. Elastollan® is the brand name for thermoplastic polyurethane (TPU) by BASF. It stands for maximum reliability, consistent product quality, and cost efficiency.

Material Details

- Product Leaflet

- Technical Data Sheet: EN, FR, ES, DE, ZH

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

Ultrafuse® TPU 85A offers a broad range of degrees of hardness with different designs, making this filament an ideal material in applications where specific degrees of flexibility are critical.

Ultrafuse® TPU 85A comes in its natural white color. Chemical properties (e.g. resistance against particular substances) and tolerance for solvents can be made available, if these factors are relevant for a specific application. Generally, these properties correspond to publicly available data on polyether based TPUs. This material is not FDA conform. Good flexibility at low temperature, good wear performance and good damping behavior are the key features of Ultrafuse® TPU 85A.

Sustainability Check

Recycled Packaging

Generally recyclable

Benefits at a Glance

- High wear and abrasion resistance

- Very good low-temperature flexibility

- High tensile strength and outstanding resistance to tear propagation

- Excellent damping characteristics

- High resistance to oils, greases, oxygen and ozone

- Biocompatible

Example Applications

- Functional flexible parts Footwear, sports and leisure

- Automotive, industrial manufacturing, agriculture, and construction

Material Properties

- Shore A Hardness: 85

- Abrasion resistance: 82mm3

- Compression set at 23°C, 72 h: 26%

- Stress at break: 34 MPa (XY), 10 MPa (ZX)

- Elongation at Break, Strain at Break: 600% (XY), 320 % (ZX)

- Tear strength: 80 kN/m (XY), 18 kN/m (XZ), 30 kN/m (ZX)

Printing Guidelines*

- Nozzle Temperature: 200-220 °C

- Build Chamber Temperature: -

- Bed Temperature: 40 °C

- Bed Material: Glass

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 15-168 mm / s**

* The product data is provided in good faith and represents typical properties based on our current knowledge and experience; these data are not to be construed as specification limits or mini- mum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application.

** To achieve faster printing speeds, it may be necessary to raise the nozzle temperature. The highest speed mentioned has been determined through our latest tests, ensuring optimal surface quality with a 0.4mm nozzle and 0.2mm layer height. Please note that as printing technology and equipment evolve, we anticipate the possibility of achieving even faster speeds in the future.

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® Flexible Filaments

Ultrafuse® TPU 64D

Ultrafuse® TPU 64D combines the best of two worlds by being a strong yet flexible filament for Fused Filament Fabrication, suitable for all FFF technologies.

Benefits at a Glance

- High resistance to oils, greases, oxygen and ozone

- High wear and abrasion resistance

Ultrafuse® TPU 95A

Ultrafuse® TPU 95A has been developed specificially to enable fast and easy printing with a flexible filament for Fused Filament Fabrication.

Benefits at a Glance

- Perfect for fast printing

- High abrasion resistance

Ultrafuse® TPS 90A

Ultrafuse® TPS 90A has been developed especially for Fused Filament Fabrication and delivers an outstandingly soft-touch surface.

Benefits at a Glance

- Soft touch

- Non-slip properties