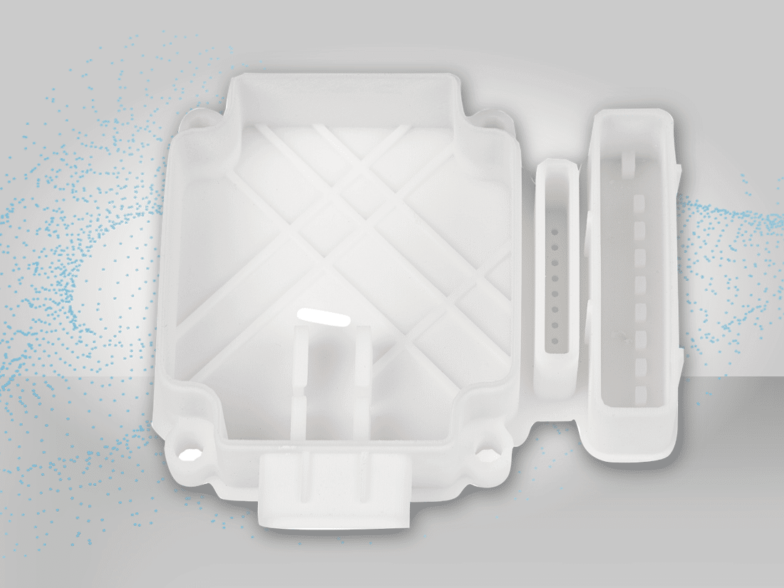

Ultrasint® PA11

Bio-Derived PA11 Powder for Durable Parts with Exceptionally High Toughness

Ultrasint® PA11 is a bio-derived powder material for advanced applications where toughness matters.

Description

It offers exceptionally high ductility and impact strength for any application requiring deformation and toughness, from automotive to medical. Ultrasint® PA11 is the perfect choice for the production of parts that need to withstand high mechanical stress, such as hinges, interior automobile parts or external fender structures. Its balanced mechanical property profile makes the material a sustainable alternative to PA12 for functional prototyping, on-demand spare parts and individualized components requiring skin contact.

Sustainability Check

Lifecycle assessment available

Carbon compensation offered

Generally recyclable

Bio-Derived

Part of Virtucycle® program

Benefits at a Glance

- Easy processing on any PBF equipment

- Exceptionally high toughness

- Does not splinter in most crash cases

- Suitable for skin contact

- Colors: White & black

Example Applications

- Car interior parts

- Bumper components

- Functional prototypes & spare parts

- Medium-load serial production parts

Material Properties

- Tensile strength: 45 MPa

- Young’s modulus: 1100 MPa

- Elongation at break: 45 %

- Charpy impact unnotched: 198 kJ/m²

- HDT B (0.45 MPa, dry): 176 °C

Print your Parts with Forward AM Materials!

Discover our comprehensive services and solutions here

Think Outside the Box with PA11

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

Ultrasint® PA11 Product Range materials

Ultrasint® PA11 Black CF

Bio-Derived, Carbon-Fibre Reinforced PA11 Powder for Highest Strength and Lightweight Design

Benefits at a Glance

- High tensile and impact strength

- Exceptionally high rigidity

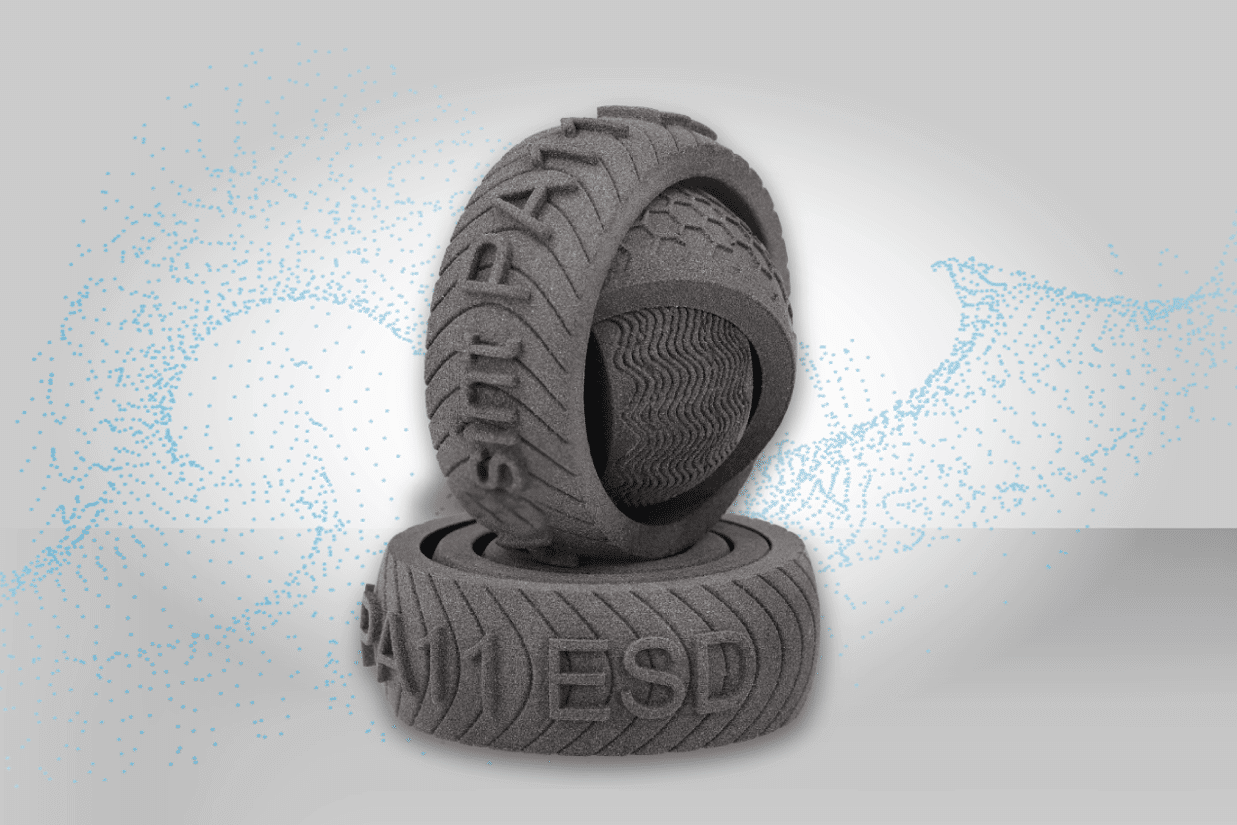

Ultrasint® PA11 ESD

Bio-Derived, Electrostatic Discharging PA11 Powder for Highest Process Safety in Application

Benefits at a Glance

- Electrostatic discharge property (ESD)

- Bio-based SLS powder