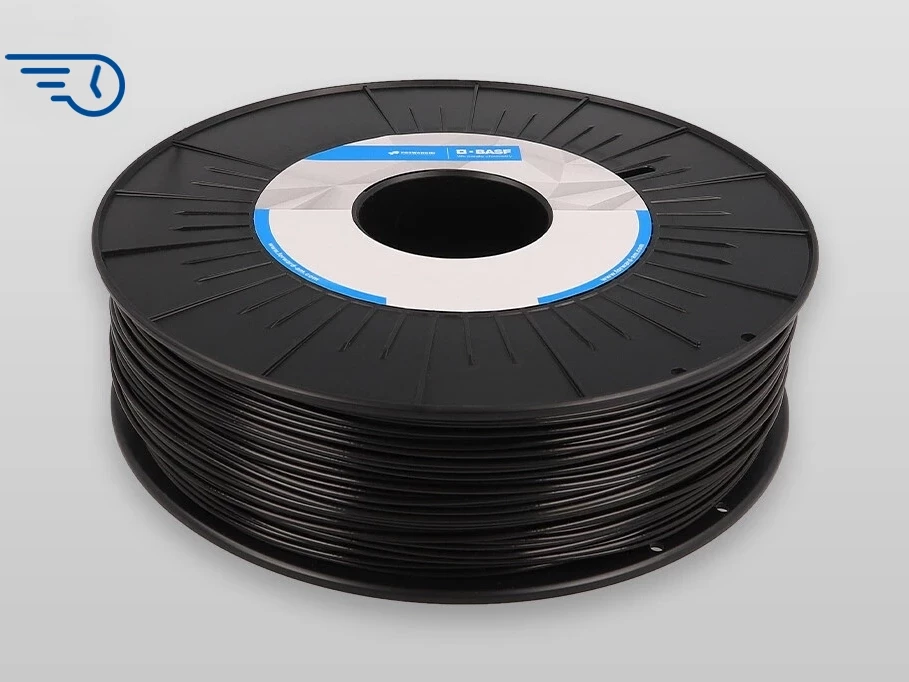

Ultrafuse® PLA

One of the most used materials for 3D printing

Ultrafuse® PLA is Poly-Lactic-Acid, a biodegradable polymer with a low melting point. It is an easy material to print with and Ultrafuse® PLA gives a smooth printing result.

Material Details

- Technical Data Sheet: EN, FR, ES, DE, ZH

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

PLA is one of the most used materials for 3D printing. Ultrafuse® PLA is available in a wide range of colors. The glossy feel often attracts those who print display models or items for household use. Many appreciate the plant- based origin of this material. When properly cooled, PLA has a high maximum printing speed and sharp printed corners. Combining this with low warping of the print makes it a popular plastic for home printers, hobbyists, prototyping and schools. Ultrafuse® PLA is based on food-safe raw materials (granulate), which are suitable for food contact applications according to the European Plastics Regulation.

Sustainability Check

Lifecycle assessment available

Recycled Packaging

Bio-Derived

Generally recyclable

Benefits at a Glance

- Large color range

- Easy to print

- High success rate

- Repeatability

- Unique properties

- Relatively low printing temperatures

- Non/extremely low warpage/shrinkage

Example Applications

- Prototyping

- Color comparison

Material Properties

- Tensile Strength (MPa): 21.2 (ZX), 34.7 (XY)

- Flexural Modulus (MPa): 1715 (ZX), 1708 (XZ), 1860 (XY)

- Elongation at Break: 1.2 % (ZX), 4.2 % (XY)

- Impact Strength Izod notched (kJ/m2): 1.6 (ZX), 2.1 (XZ), 3.3 (XY)

- Impact Strength Izod unnotched (kJ/m2): 4.7 (ZX), 9.6 (XZ), 11.0 (XY)

- HDT @ 0.45 MPa: 65 oC

Printing Guidelines*

- Nozzle Temperature: 210-230 °C

- Build Chamber Temperature: -

- Bed Temperature: 50 - 70 °C

- Bed Material: Glass

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 40-80 mm / s

*The product data is provided in good faith and represents typical properties based on our current knowledge and experience; these data are not to be construed as specification limits or mini- mum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application.

Quality

We select the best raw materials available from renowned suppliers. Dedicated people, highest standards. Production on our state-of-the-art computer-controlled machinery guarantees a truly consistent filament, also between colors and batches.

It will perform as expected, every time.

Use Cases and Whitepaper of Ultrafuse® PLA

How Additive Manufacturing Lends a Helping Hand

3D printed highly functional prosthetic device at low-cost - Access to a prosthesis can raise an amputee’s quality of life tremendously.

PlastiPUSH Hand Spikes

Every car driver out there knows it only too well – just a split second of distraction and the car bodywork shows an annoying dent. Plastic fender…

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® Standard Filaments

Ultrafuse® rPET

Sustainability Meets High Performance with Ultrafuse® rPET

Benefits at a Glance

- Sustainable alternative to PET

- Easy to print Great end results

Ultrafuse® PP

Ultrafuse PP is a high-performance thermoplastic with low density, high elasticity, and high resistance to fatigue.

Benefits at a Glance

- Tough and strong

- Fatigue resistant

Ultrafuse® PET

Ultrafuse PET is made from a premium PET and prints as easily as PLA but is much stronger.

Benefits at a Glance

- Watertight prints possible

- Easy to print like PLA

- Premium food-approved raw material

- Good layer adhesion

- Easy to handle

Ultrafuse® ABS

Strong, flexible, and has a high heat resistance. ABS is a preferred plastic for engineers and professional applications.

Benefits at a Glance

- Long life span

- Very tough