How Additive Manufacturing Lends a Helping Hand

3D printed highly functional prosthetic device at low-cost

In developing countries, there is a high percentage of upper-limb amputees due to several reasons – ranging from inaccessibility to health care, an overall unsafe environment, and living conditions to war. Access to a prosthesis can raise an amputee’s quality of life tremendously and has the potential to enable them to pursue gainful employment for a self-determined life. By leveraging Additive Manufacturing, Forward AM’s filament Ultrafuse® PLA, and a dedicated network of clinicians in developing countries, the Victoria Hand Project tackles this challenge.

Project Breakdown

Industry

Medical

Product

Ultrafuse® PLA

Why Forward AM?

Perfect-fit material

The result

3D printed highly functional prosthetic device at low-cost

Challenge: Creating a fully functional prosthesis – on-site, on-demand, personalized

The World Health Organization estimates that 2.4 million of the 3 million upper-limb amputees worldwide live in developing countries, yet only 5% of this population has access to prosthetic care [1],[2]. Governments and public healthcare systems in developing countries cannot cover the high costs of prosthetic devices, and with many people in these areas relying on labor-intensive occupations for their primary source of income, upper-limb amputations can leave families entrenched in a cycle of poverty [2]. Victoria Hand Project, a Canadian charity and non-profit organization, has a mission to provide upper-limb prostheses to amputees with limited or no access to prosthetic care.

[1] M. LeBlanc, “Give Hope – Give a Hand – The LN-4 Prosthetic Hand”, November 2008.

[2] B. Phillips, G. Zingales, S. Ritter, and K. Mehta, “A review of current upper-limb prostheses for resource-constrained settings,” 2015 IEEE Global Humanitarian Technology Conference (GHTC), 2015

Solution: Combining Forward AM’s Ultrafuse® PLA and the right partners

The result of years of engineering and development is a low-cost, highly–functional, 3D-printed upper-limb prosthesis: The Victoria Hand. By combining advanced and cost-effective tools – Additive Manufacturing, 3D scanning, and 3D software – the Victoria Hand is fabricated directly within the countries where they are needed and used. In collaboration with a network of international clinical partners and healthcare providers, the Victoria Hand is made available to amputees throughout the world.

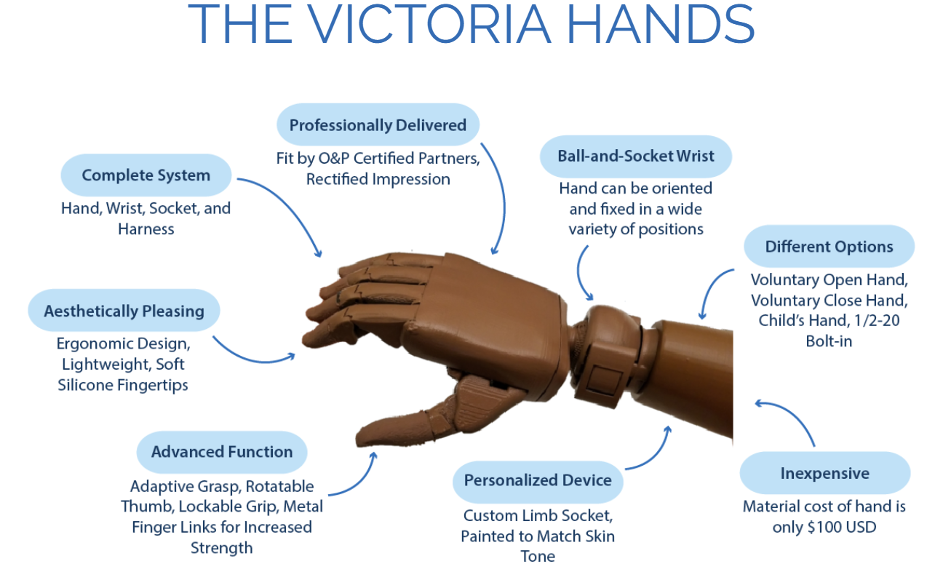

Let’s take a closer look at the Victoria Hand:

The Victoria Hand is a complete system, comprising the hand, wrist, socket, and harness. It provides advanced functionality with an adaptive grasp, a rotatable thumb, a lockable grip, and metal finger links for increased strength. A user can adduct or abduct the thumb, to achieve different positions for many different grasps, creating a hand that can assist the user for many more in their daily life. This includes a one-finger pinch, a two-finger pinch, a power grasp, or a lateral grasp.

To help as many amputees as possible with widely ranging variations in limb difference, each limb socket is completely customized to the user, using 3D scanning and 3D printing, to create a comfortable fitting socket.

For many amputees, having an inconspicuous prosthetic is highly valued, to avoid social stigma and unwanted attention. In addition to its natural shape, the Victoria Hand and socket are painted with colors that closely match the user’s skin tone. To ensure a long-lasting finish, these hands must be printed with a high-quality material that the paint can adhere well to, without chipping off or affecting the strength.

Using Forward AM’s filament Ultrafuse® PLA, the Victoria Hand can be manufactured to last a long time in harsh environments, while having a natural look. Being one of the most widely used materials for Additive Manufacturing, Ultrafuse® PLA enables consistent quality parts, making each hand a convincing print result. Its compatibility with all open Fused Filament Fabrication (FFF) shows a low access barrier combined with high and reliable quality. This filament is also exceptionally easy to print – perfectly suited for production in print centers in developing countries.

As it is key that the prostheses are available where they are needed, the Victoria Hand Project cooperates with clinics in the respective countries. VHP’s deployment system has three primary features:

- A transferable production and fabrication system in the countries where the prosthetic devices are needed

- Professional provision of prostheses to amputees through clinical intermediaries with medical practitioners

- Training and support of both the production network and the clinical provision network

Result: A helping hand where it’s needed most

By harnessing the benefits of Additive Manufacturing, the Victoria Hand Project developed a fully functional, low-cost prosthesis and makes it available where it’s needed – in developing countries where patients have limited to no access to healthcare systems. By building up a network of clinics and installing local print centers, amputees have access to the Victoria Hand – and a chance to regain the ability to do home or work-related tasks and improve their quality of life.

“By using Forward AM’s Ultrafuse® PLA we have been able to increase the quality of our printed parts and reduce assembly time, allowing users to receive their custom prosthetic arms in less time.”

Michael Peirone, CEO, Victoria Hand Project.

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!