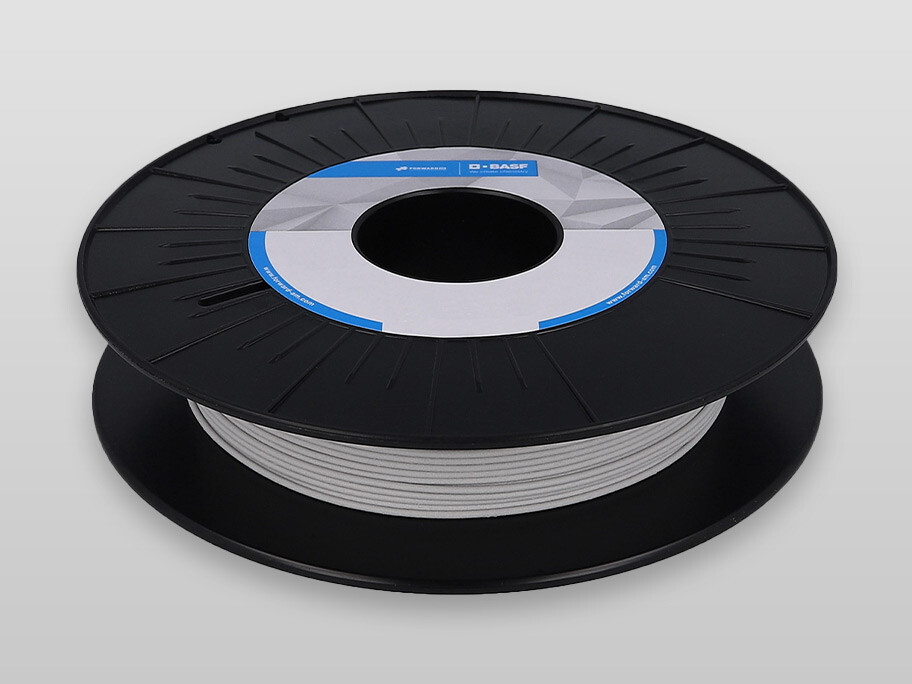

Ultrafuse® Support Layer

Exclusively available for Europe Market

This product is intended exclusively for sales, distribution, and use within the European Union, Albania, Iceland, Liechtenstein, Monaco, North Mace- donia, Norway, San Marino, Serbia, Switzerland, Turkey, and the United Kingdom and is only available for our customers located in those countries. *

Read everything you need to know about working with Metals on our Metal Solution page. Ready to debind and sinter parts? Read more about D&S or create an account or sign in and order directly.

Material Details

- Technical Data Sheet: EN, FR, ES, DE

- User Guidelines Support Layer

- User Guidelines Metal

- Debinding Simulation Guidelines

- Process Guidelines

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

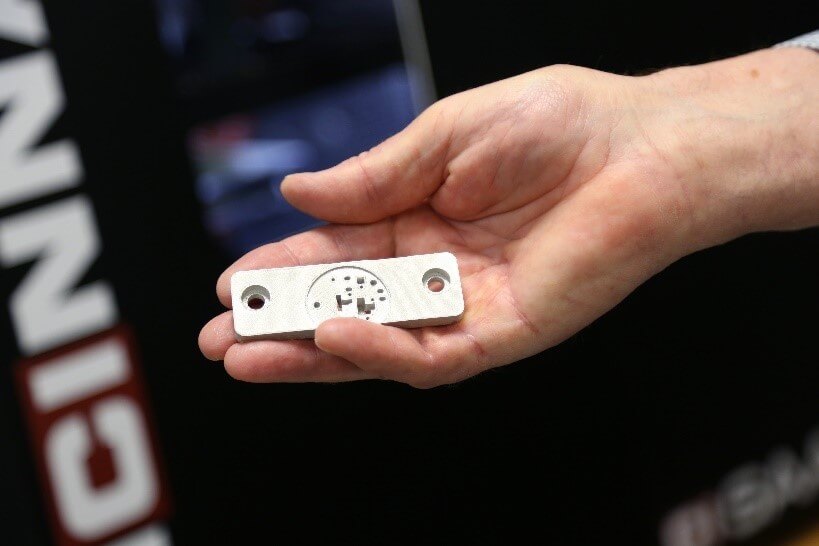

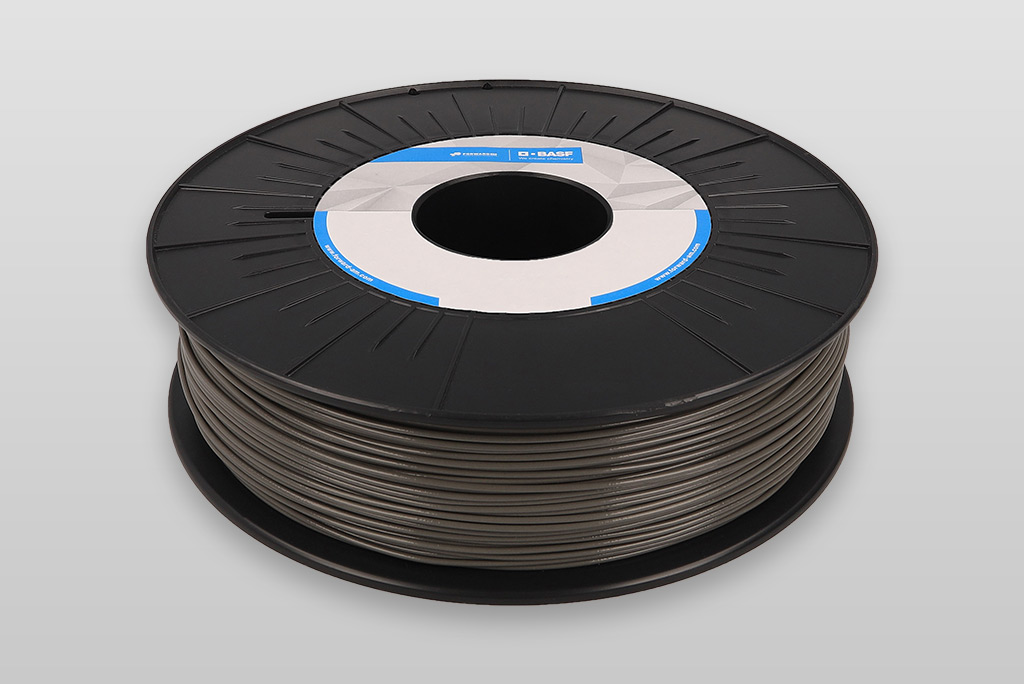

Ultrafuse® Support Layer filament developed to be used in combination with Ultrafuse® Metal Filaments. When printed between support and the object, it creates a barrier during sintering and facilitates the separation of support from the metal part. Ultrafuse® Support Layer is not developed to print stand-alone parts and should be printed as a layer attached to the support structures in dual extrusion prints.

Benefits at a Glance

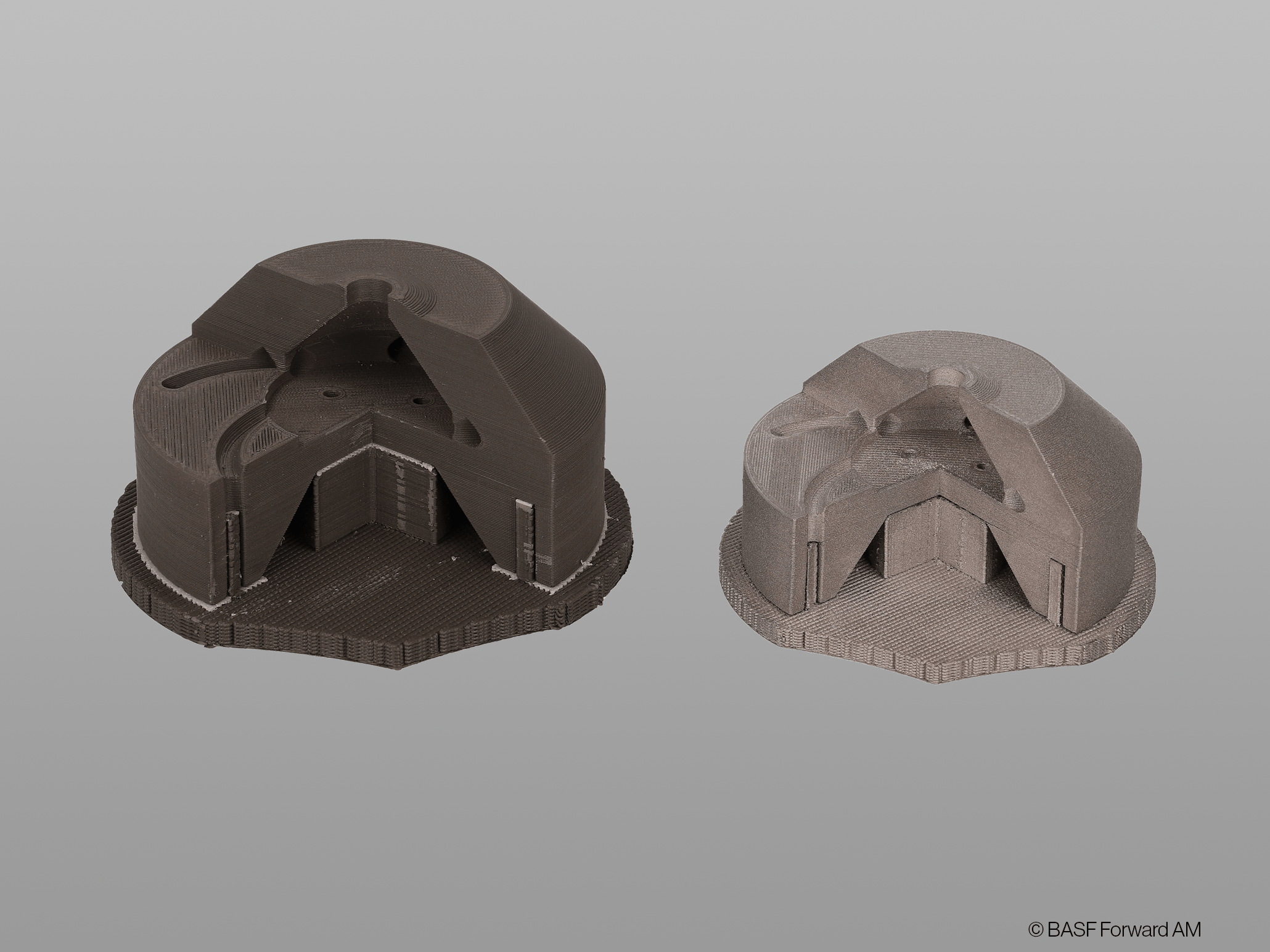

Ultrafuse® Support Layer is uniquely designed for FFF printing of Ultrafuse® 316L and 17-4PH filaments and prevents the support from sintering to the printed part

- Printable on any metal FFF printer*

- Allows for a wider range of designs and complex geometries to be printed

- Excellent surface quality of supported areas of the part

- Minimize the distortion of the printed part during debinding and sintering

- Simplified workflow for preparing parts for sintering

* A hardened, coated or ruby nozzle is recommended for printing

Example Applications

- Tooling

- Jigs and fixtures

- Series production of full metal parts

- Functional parts and prototypes

Printing Profiles

Select the printer brand you work with to access your printer profile. Click here to learn more about how to work with printer profiles.

*This product is not intended for sale, distribution or use in the US and Canada and is not available to our customers in those countries.

While the descriptions, designs, data, and information contained herein are presented in good faith and believed to be accurate, it is provided for in- spiration only. Because many factors may affect processing or application/use, we recommend that you perform independent tests to determine the suitability and proper use of a product for your particular purpose.

NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE MADE REGARDING PRODUCTS DESCRIBED HEREIN, OR THAT THIS CONTENT MAY BE USED WITHOUT INFRINGING THE INTELLECTUAL PROPERTY OF OTHERS. IN NO CASE SHALL DESCRIPTIONS, INFORMATION, DATA, OR DESIGNS DESCRIBED HEREIN BE CONSIDERED A PART OF OUR TERMS AND CONDITIONS OF SALE.

Print your Parts with Forward AM Materials!

Discover our comprehensive services and solutions here

Q&A about Ultrafuse® Support Layer

In which markets Ultrafuse® Support layer will be available for sale and use?

-

- Ultrafuse® Support Layer initially will be available for sales and use in the European Union, Albania, Iceland, Liechtenstein, Monaco, North Macedonia, Norway, San Marino, Serbia, Switzerland, Turkey, and the United Kingdom.

What is this ´Declaration´ and why do I need to sign it?

-

- Currently we have green light for sales and use in the countries mentioned above. Due diligence for other regions are continueing. In order to fulfil our internal compliance rules, we kindly ask your support and request from you to sign the declaration. Standard template is available and will be shared on request.

Will other countries be added to this list in the future?

-

- Due dilligence is ongoing, we cannot currently confirm when Ultrafuse® Support Layer is going to be available in other regions. We will let you know once the process is finished.

When is Ultrafuse® Support layer available for sale?

-

- We will launch the material Tuesday the 24th of May. Our sales partners can place an order as soon as this information is received. Orders can be processed only after ´declaration´ is signed.

Use Cases of Ultrafuse® Metal Solution

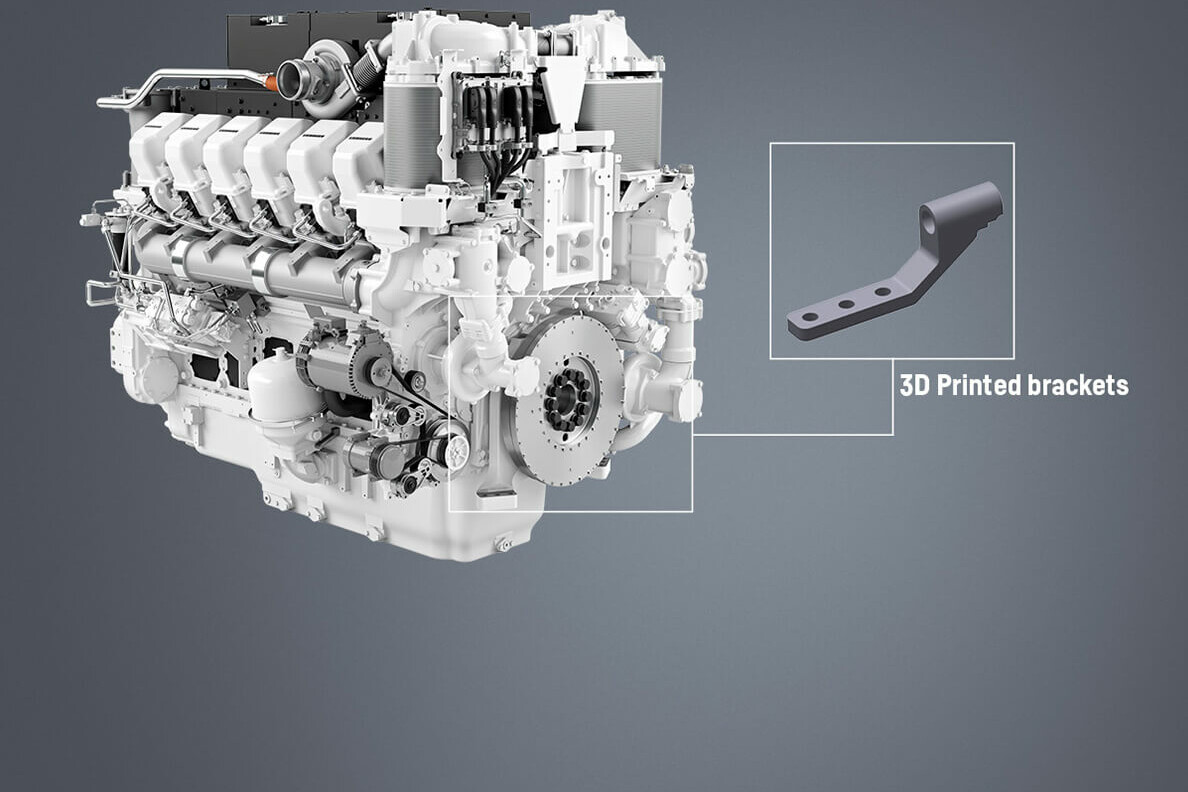

Engine Bracket

When migrating from traditional manufacturing methods to Additive Manufacturing, an experienced and trustworthy AM expert partner is the decisive…

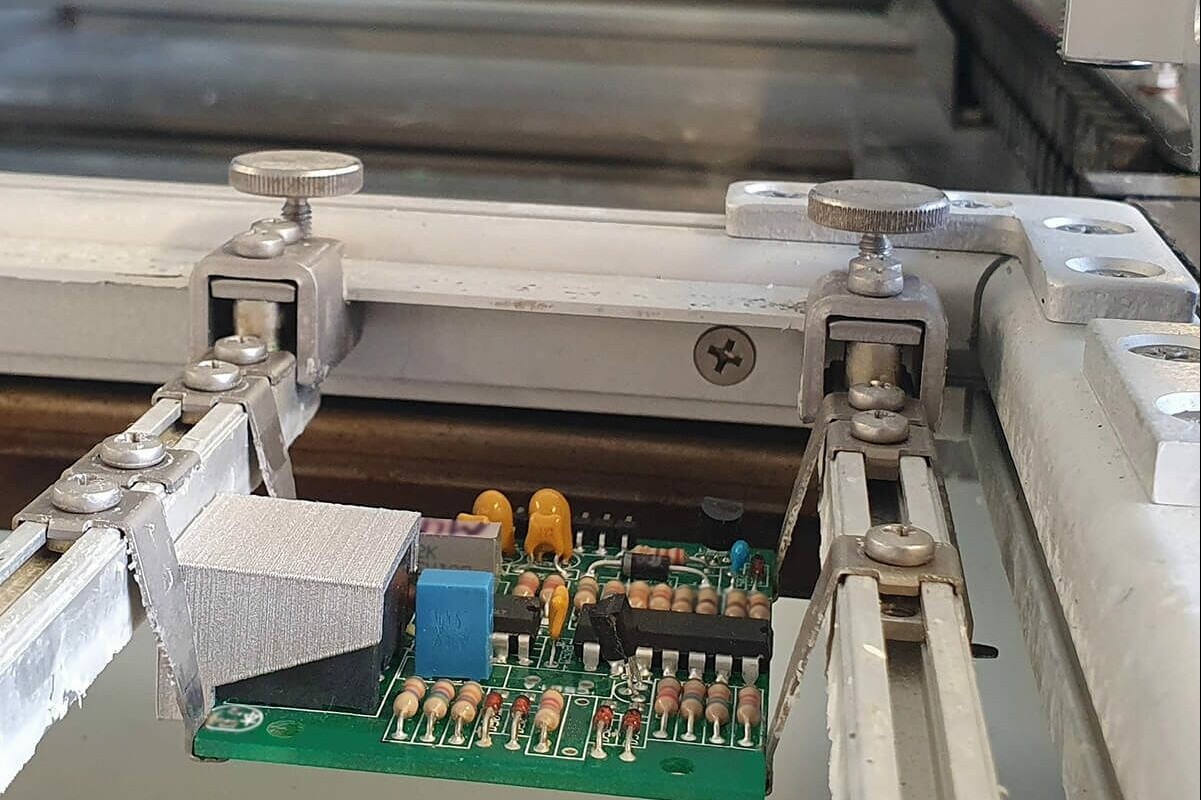

Cover Cap for Electronic Boards

When it comes to the electronics industry, Additive Manufacturing (AM) offers various advantages for manufacturing companies – including faster time…

Tooling Fixtures

Electronic communication systems, avionics, space intelligence, cyber security and weather monitoring solutions – American company L3HARRIS…

Next Steps

Printing Profiles

Select your printer below to access your printer profile. Click here to learn more about how to work with printer profiles.

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Metal Filaments

Ultrafuse® 17-4 PH

The Filament Enabling Stainless Steel Parts for Applications that Require High Hardness and Mechanical Strength

Benefits at a Glance

- High mechanical strength and hardness

- Easy and affordable way of metal 3D printing

- Good corrosion resistance

- Fully hardened enables highest strength

- Wide range of post-processing options for green parts

Ultrafuse® 316L

Stainless Steel Composite Metal Filament for 3D Printers

Benefits at a Glance

- Easy and affordable metal 3D printing

- Fast material exchange and easy handling

- For all open-source FFF printers

- Produces parts of stainless-steel 316L metal

- Uniform particle distribution enhances mechanical properties