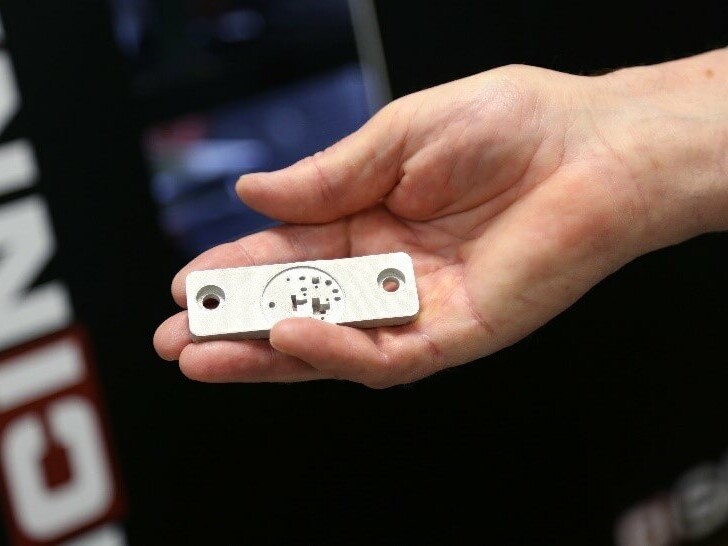

Tooling fixtures

Cost-effective Metal AM with L3HARRIS

Electronic communication systems, avionics, space intelligence, cyber security and weather monitoring solutions – American company L3HARRIS Technologies is a proven leader in numerous business segments, across air, land, and cyber domains. Headquartered in Melbourne, Florida, with 50,000 employees and customers in 130 countries, L3HARRIS Technologies is a true global player.

Project Breakdown

Industry

Industrial applications

Project

Tooling fixtures

Why Forward AM?

Perfect-fit metal filament for serial production

Forward AM materials used

Ultrafuse® 316L

The result

High-quality metal parts

Solution suitable for industry sectors

Jigs & fixtures, tooling, jewelry

Fixturing Components – Keeping It All Together

What do all these industries have in common? And how does Additive Manufacturing (AM) come into play? It’s in the details. Across all its business segments, L3HARRIS requires fixturing components, e.g. for clamping or spacing parts during assembly – and 3D printing is just perfect for manufacturing these. As an industry innovator, L3HARRIS Fuzing & Ordnance Systems was an early adopter of metal AM. The company initially 3D printed metal parts at service bureaus on a regular basis, but quickly decided to increase their AM metal capabilities, so L3HARRIS started looking into ways to do exactly that at maximum cost-effectiveness. They wanted a technology that could satisfy manufacturing tooling applications but would also be an excellent fit for product development.

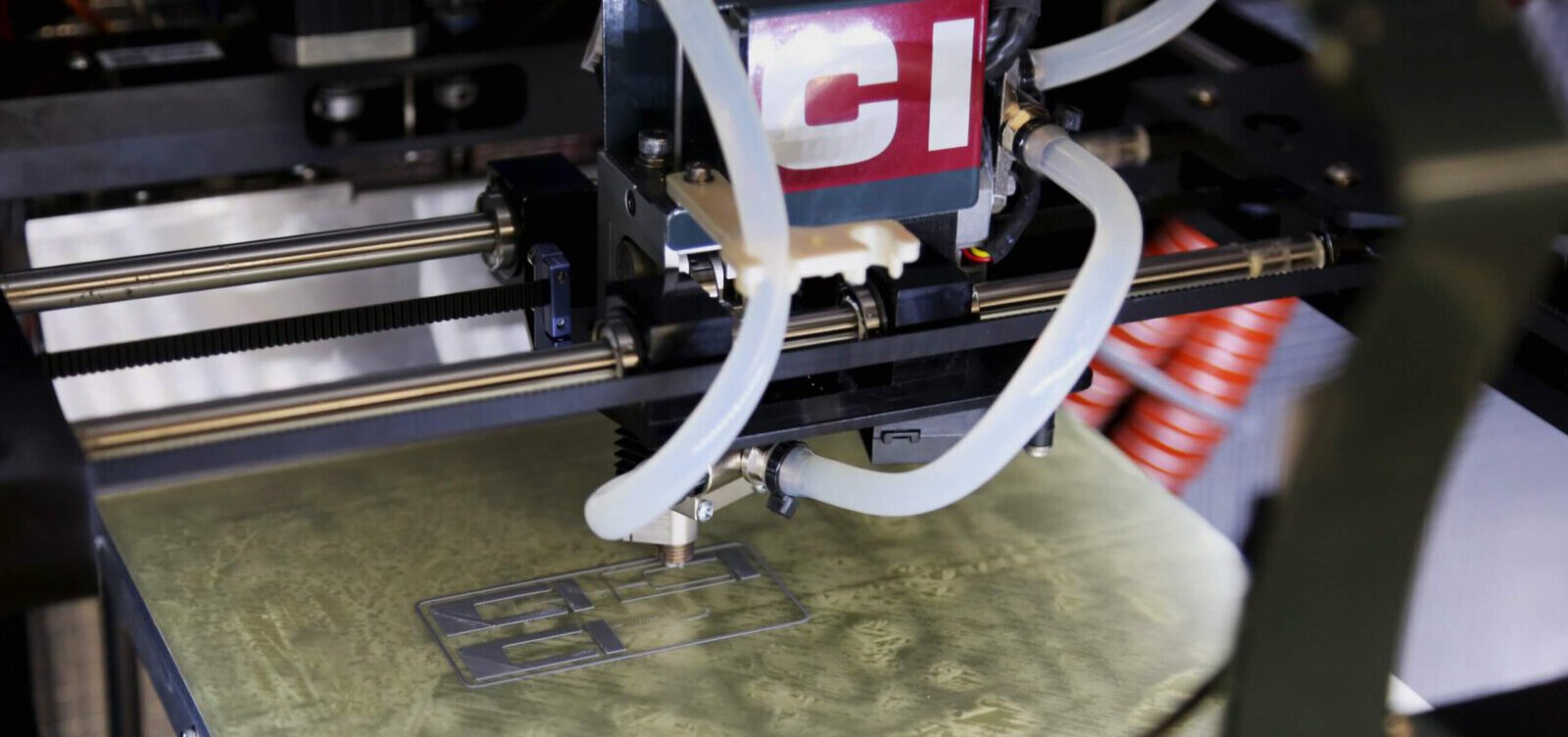

L3HARRIS Fuzing & Ordnance Systems decided to purchase a SAAM HT (Small Area Additive Manufacturing High Temperature) machine from Cincinnati Incorporated. However, L3HARRIS was fully aware that the printer is only one half of the story: To succeed, a proven, reliable and easy-to-handle material is crucial – ideally one that’s already well established in the MIM (metal injection molding) industry for Fused Filament Fabrication (FFF). L3HARRIS, therefore, opted to test Ultrafuse® 316L, an advanced metal filament from Forward AM.

The Material used

Forward AM’s Ultrafuse® 316L is a metal polymer composite filament for the production of metal components in 316L stainless steel. It enables manufacturing by using conventional Fused Filament Fabrication machines, followed by an industry standardized catalytic debinding and sintering process. The filament has a non-slip surface, allowing it to be applied in most Bowden or direct-drive extruders. Thanks to its high flexibility, it can be fed through complex idler pulleys and multiple filament transportation systems in printers – with no extra drying required.

Available at an attractive Total Cost of Ownership, Ultrafuse® 316L enables easy and affordable metal 3D printing. It’s a perfect fit for tooling applications and suitable from serial production to functional prototypes. In short, Ultrafuse® 316L is the perfect solution to partner with the Cincinnati SAAM HT printer.

When comparing AM to conventional machining costs, the numbers speak for themselves. By choosing 3D printing in combination with Forward AM’s filament Ultrafuse® 316L, L3HARRIS was able to reduce their cost by more than 35%.

Cost Savings for Tooling Fixture

|

Method

|

Material

|

# of Parts

|

Total Cost

|

|

Additive Materials

|

Ultrafuse® 316L

|

50

|

$3,806.70

|

|

Traditional Machining

|

316 SS

|

50

|

$6,125.00

|

Note: 50 tooling parts were printed and finish-machined. The cost savings of Additive Metals over 100% machining were $2,318.

*Total Cost includes all costs from material, manufacturing, debinding & sintering, and post-machining.

Result: High quality metal 3D printing saves time and cost

The time invested in expanding its AM capabilities paid off handsomely for L3HARRIS Fuzing & Ordnance Systems.

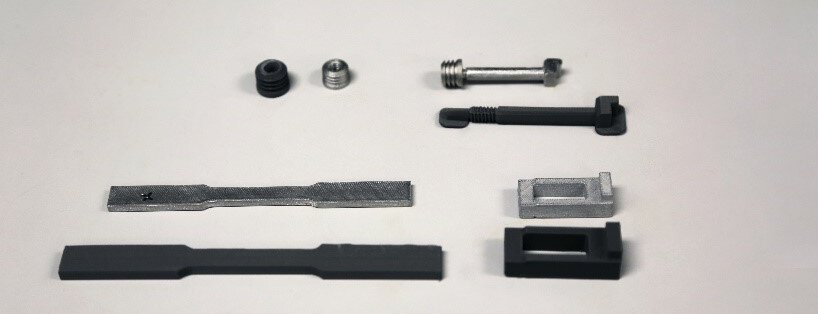

By using Forward AM’s metal filament, L3HARRIS was immediately able to produce safe, assembly-ready and affordable stainless steel fixturing components, tooling for clamping parts, and spacing parts. In addition, the company was also able to use it to speed up product development for housings and other small components. As hard evidence of the quality of the 3D printed components, prototypes using Ultrafuse® 316L metal filament meeting rigorous specifications were used in U.S. Defense Department test programs.

“Forward AM’s solution enabled us to achieve high quality metal part printing with an affordable desktop 3D printer. The great advantage is that we can also use other Forward AM polymer materials in the same machine.”

Mark Holthaus, Lead Designer/Additive Lead, L3HARRIS, Fuzing & Ordnance Systems.

With a now proven concept, L3HARRIS introduced Forward AM’s Ultrafuse® 316L into its development cycle. Pairing this advanced material with a standard desktop 3D printer has proven to be a highly cost-effective, efficient, and faster alternative to traditional machining processes. The ease of use and sheer speed provides for more design freedom during the investigation and development phase, while greatly enhancing the quality and reliability of the components produced.

For this mission, Forward AM also partnered with DSH Technologies, an independent specialist for reliable debinding and sintering. This allowed L3Harris to go directly into metal printing its components. The relationship proved to be the perfect solution for L3HARRIS Fuzing & Ordnance Systems, enabling them to focus on printing top quality green parts while not having to worry about other steps in the metal FFF process.

Share this page

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!