Blazing the Comfort Trail

Perfect-fit material for lattice structures

Backpacks are our everyday companions. In everyday life, business trips, leisure travel and hiking, they are our trusty sherpas when we need to carry a load in comfort while keeping our hands free. Especially longer treks make it rapidly and very uncomfortably clear if our backpack doesn’t make the grade, both ergonomically and functionally.

Project Breakdown

Industry

Consumer Goods

Product

Ultrasint® TPU01

Why Forward AM?

Perfect-fit material for lattice structures

The result

Enhanced backpack carrying experience through 3D printed lattice comfort elements at reduced assembly time and cost

Challenge: No-sweat Hiking

Hiking enthusiasts know the feeling all too well: Uncomfortable equipment quickly kills the joy of the Great Outdoors. The touchpoints between the body and the backpack are vital to comfort – if these don’t perform well, friction and heat followed by sweat, persistent dampness, soreness and unpleasant odor are the result.

Leading German AM polymer processing specialist OECHSLER tackled the challenge of developing a whole new backpack generation, aiming at enhancing the hiker’s carrying experience. Rethinking backpack functionality from zero, they asked themselves two fundamental questions. What would be the perfect waistbelt hip-fin design to maximize wearer comfort – and how could already “ergonomic” back padding possibly be improved?

Solution: Lattices 3D printed with Ultrasint® TPU01

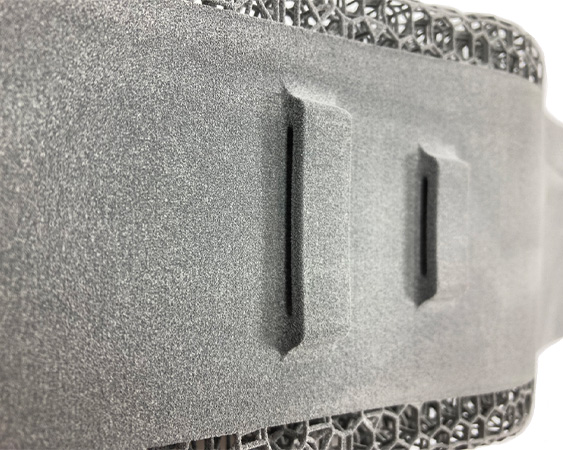

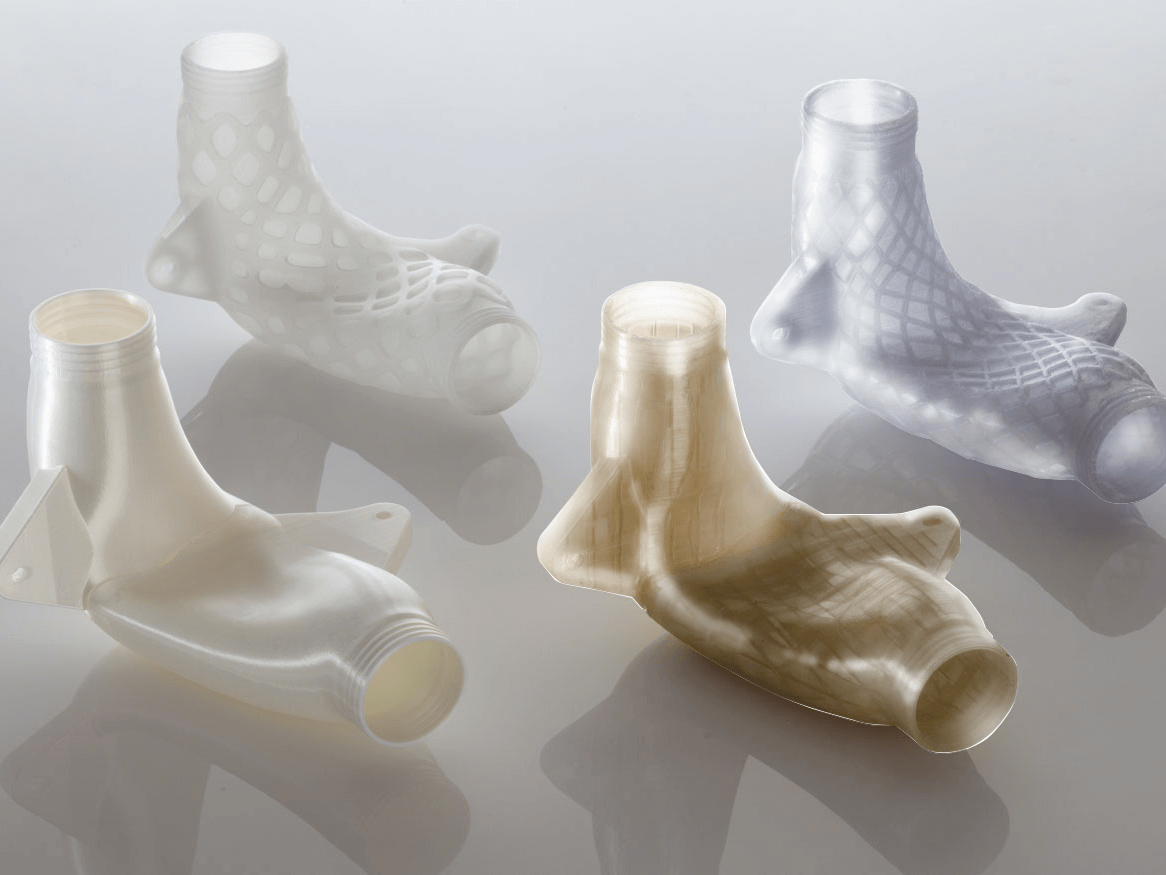

OECHSLER’s radical new approach completely replaces the foam conventionally used in backpack waistbelts and back paddings with 3D-printed lattice comfort elements. Thanks to freely designable lattice structures only possible with Additive Manufacturing, a fully integrated cushioning system unlocks vastly superior comfort. The open-cell structure of the 3D printed back pads and hip fins maximizes ventilation and minimizes heat accumulation, thus significantly reducing body touchpoint temperature and humidity build-up.

Furthermore, this highly innovate lattice design significantly reduces maximum and mean body-contact pressures. The smart lattice geometry makes the cushioning characteristics adjustable through precisely calibrated variations in the strut thickness and overall size of the lattice element. Specific areas can be designed to deliver different degrees of rebound and rigidity to maximize cushioning properties and wearer comfort.

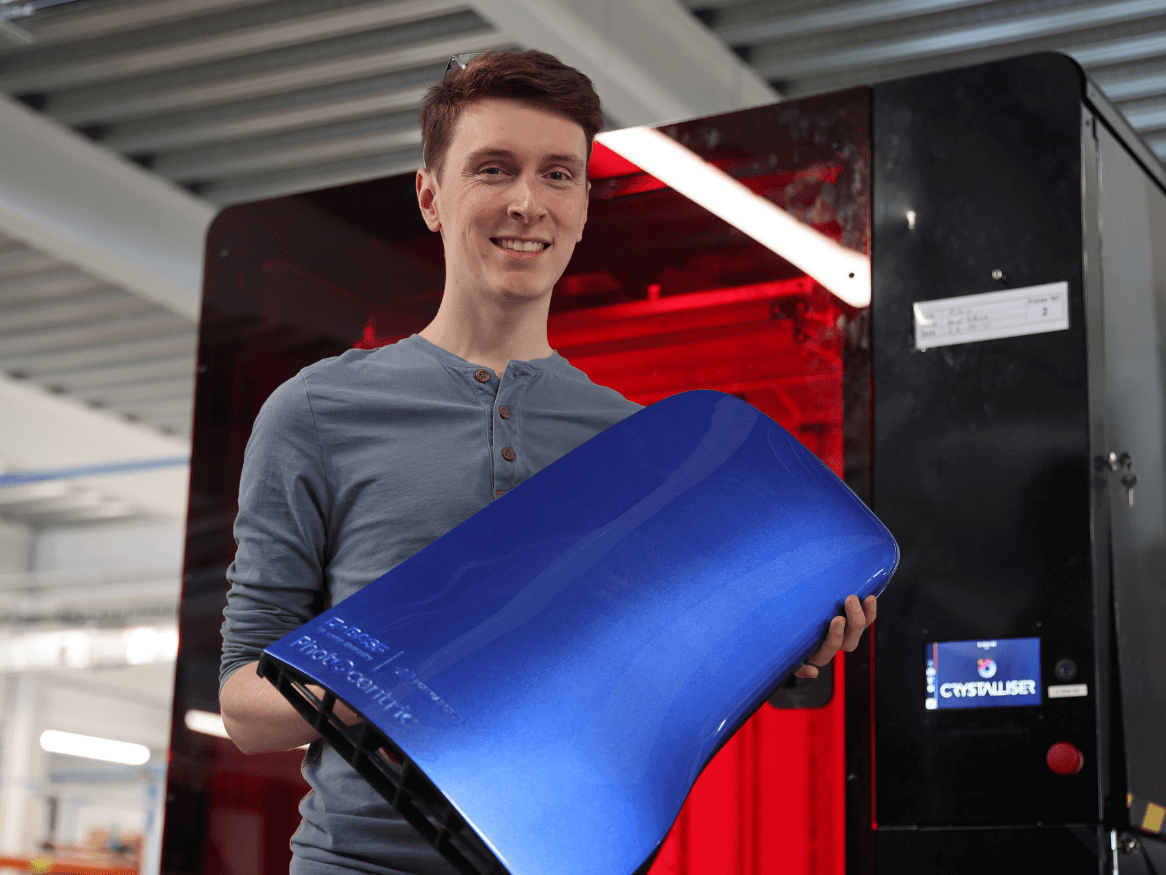

Taking a closer look at the material bringing this new approach to life, Forward AM’s Ultrasint® TPU01 is the perfect fit. This high-performance polymer powder makes 3D printing flexible lattice structures simple, rapid and highly cost-effective. The highly processable multi-purpose material is explicitly designed for HP’s 5200 series Multi Jet Fusion printers – and with one of the highest throughputs for flexible materials it convinces with very high process stability and ease of use.

Thanks to the material’s great abrasion resistance, it doesn’t pose a challenge that the 3D printed parts are constant friction with the wearer’s body – TPU allows a reliable and durable part performance. The combination of lattice structures and TPU01 results in lightweight parts – a clear benefit for the wearer. Even better, having successfully passed skin sensitization and cytotoxicity tests to the demanding ISO 10993-10 and ISO 10993-5 standards, this advanced material can be used in applications in contact to the human body with complete peace of mind. Topping it off, Ultrasint® TPU01 shows excellent UV and hydrolysis resistance – all in all, it’s an outstanding match for outdoor sports such as hiking, even on rainy days.

Underlining Forward AM’s commitment to environmental sustainability, Ultrasint® TPU01 not only supports a very low-waste manufacturing process; as it’s a thermoplastic, this material can be recycled easily at the end of the product’s useful life, fulfilling Forward AM’s circular economy principle and meeting one of the key sustainability requirements for modern outdoor gear.

The two different examples below show the versatile material and design options that are opening up unlimited flexibility regarding function, comfort and visuals:

Focusing on the benefits to the manufacturer, the back pads and hip fins can be produced as a single lattice element – meaning a huge reduction in assembly steps, time and ultimately cost, as no gluing or sewing is required.

Result: Next-level comfort, sustainability and cost-efficiency

Thanks to the new 3D printed integrated lattice comfort pads, the trekking backpack delivers a completely new carrying experience with a wide range of benefits:

- Maximized air ventilation

- Significantly reduced temperature and relative humidity accumulation at the contact area to the hiker’s back

- Reduced maximum and mean contact pressures

- Adjustable damping characteristics through different degrees of hardness in a single printed element

- Unlimited design flexibility

- Easy, rapid assembly resulting in a huge cost and time reduction

- 100% recyclability of the 3D printed material

“Back pads and hip fins represent the key interface between the hiker and the trekking backpack. By leveraging Additive Manufacturing with Forward AM’s Ultrasint® TPU01, we have achieved a completely new level of comfort combined with outstanding functionality. As a passionate hiker myself, I am convinced that this will revolutionize backpack manufacturing.”

Leonhard Klein, Program Manager AM Lattice, OECHSLER.

Additive Manufacturing is opening up whole new frontiers in product creation for the outdoors. Forward AM’s materials make products almost infinitely designable, superbly comfortable, versatile, sustainable and lightweight – and make product development faster and more cost-efficient than ever before. By leveraging lattice structures with Ultrasint® TPU01 by Forward AM, product designers now have complete freedom, the power to incorporate multiple hybrid features in just one 3D print, and can achieve the perfect symbiosis of design flexibility and comfort. The result is a next-generation trekking backpack that delivers the performance and sustainability that today’s outdoor enthusiasts demand.

We’re ready to support your project with Additive Manufacturing – simply get in touch!

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!