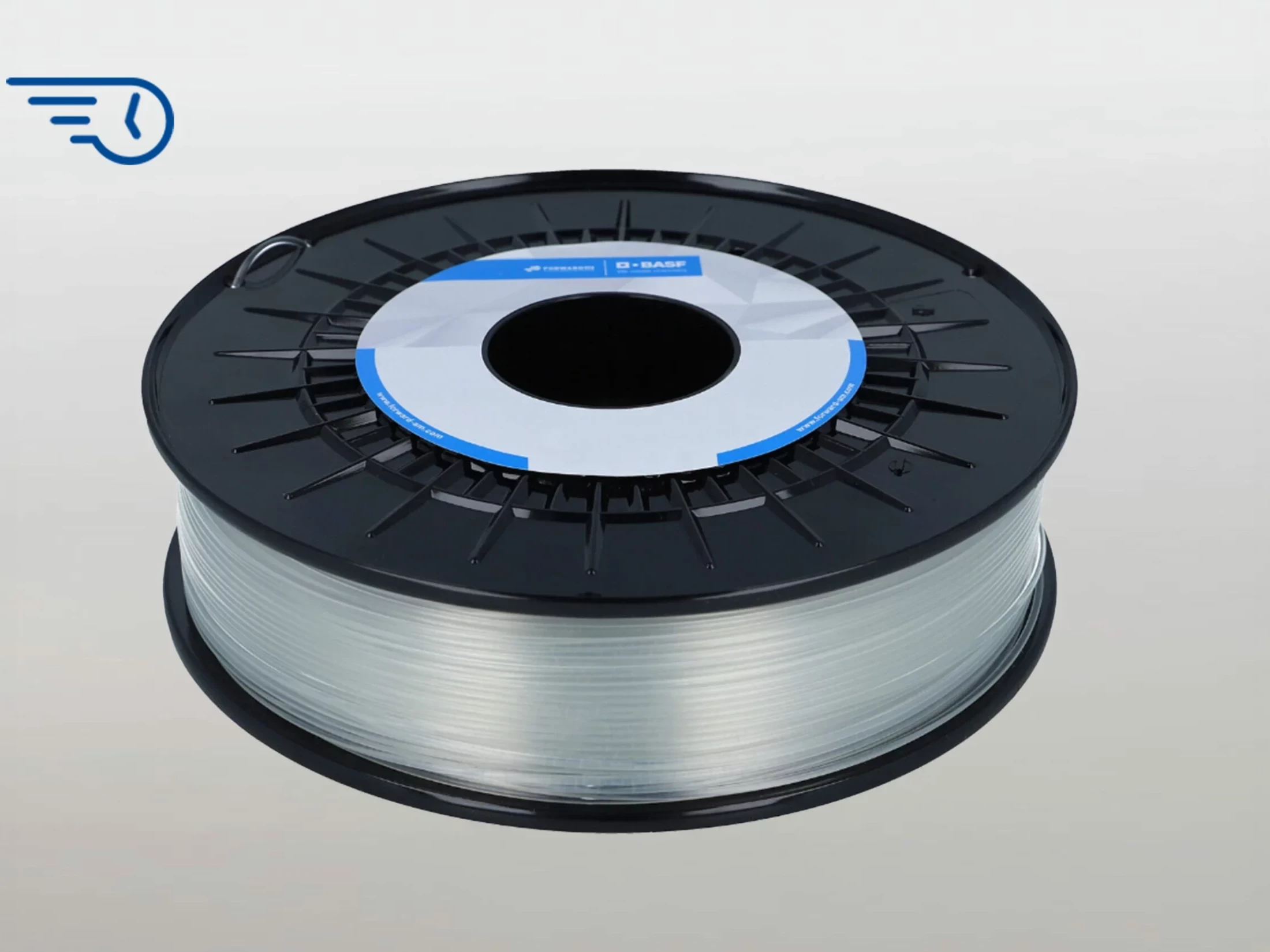

Ultrafuse® PA

First BASF Filament Development Based on Ultramid®

The key features of Ultrafuse PA are the high strength and high modulus. Furthermore, Ultrafuse PA shows a good thermal distortion stability.

Material Details

- Product Leaflet

- Technical Data Sheet: EN, FR, ES, DE, ZH

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

Ultrafuse® PA is the translation of BASF ́s Ultramid® to the 3D printing space. It is based on a copolyamide 6/66 grade of intermediate viscosity. With Ultrafuse® PA, it is possible to print semi-flexible thin parts; however, it is very rigid at higher thicknesses. It has a lower melting temperature than PA6 and PA66, meaning it can be printed at a lower temperature and also has better impact resistance versus PA6 and PA66, opening up a whole new application field for end-users.

Sustainability Check

Recycled Packaging

Generally recyclable

Benefits at a Glance

- Good fatigue resistance

- High mechanical strength

- Low melting point makes it printable for many FFF printers

- Good wear resistance/ lubricity

- Good impact resistance at low temperatures

Example Applications

- Most engineering sectors

- Suitable for a wide range of different components and machine elements, such as high-grade electrical insulation material

Material Properties

- Tensile Strength (MPa): 16.4 (ZX), 61.4 (XY)

- Flexural Modulus (MPa): 2149 (ZX), 2246 (XZ), 2051 (XY)

- Elongation at Break: 0.8 % (ZX), 9.6 % (XY)

- Impact Strength Izod notched (kJ/m2): 1.7 (ZX), 3.9 (XZ), 5.8 (XY)

- Impact Strength Izod unnotched (kJ/m2): 3.2 (ZX), 45.6 (XZ), 28.0 (XY)

- HDT @ 0.45 MPa: 135 oC

Printing Guidelines*

- Nozzle Temperature: 220-250 °C

- Build Chamber Temperature: -

- Bed Temperature: 90 - 120 °C

- Bed Material: Glass + PVA / Kapton tape / PA adhesive

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 30 -60 mm / s

*The product data is provided in good faith and represents typical properties based on our current knowledge and experience; these data are not to be construed as specification limits or mini- mum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application.

Next Steps

Standard Printing Profiles

Select your printer below to access your printer profile. Click here to learn more about how to work with printer profiles.

High Speed Printing Profiles

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® Engineering Filaments

Ultrafuse® PLA PRO1

PLA PRO1 is an extremely versatile, tough biobased PLA filament made for professionals.

Benefits at a Glance

- Speed: Reduce your printing time by 30% – 80%, (subject to printer/ object limitations)

- Strength: Excels overall beyond printed ABS in mechanical properties

Ultrafuse® ABS Fusion+

Ultrafuse® ABS Fusion+ is an easy-to-print engineering material and enables a much more efficient printing process.

Benefits at a Glance

- Easy to print

- Direct printing on heated glass or print bed surfaces

Ultrafuse® ASA

Ultrafuse ASA is a high-performance thermoplastic and offers additional benefits such as high outdoor weather resistance

Benefits at a Glance

- UV stabilized

- Weather resistance

Ultrafuse® PC/ABS FR

Ultrafuse® PC/ABS FR Black is a V-0 flame retardant blend of Polycarbonate and ABS – two of the most used thermoplastics for engineering & electrical applications

Benefits at a Glance

- Fulfills flame retardancy according to UL 94 V-0 (@1.5mm & 3.0mm)

- Outstanding aesthetics