Ultracur3D® Photopolymers

Reactive Urethane Photopolymers

Ultracur3D® reactive urethane photopolymers deliver class-leading performance and consistency to meet your specific application needs, while accelerating design iterations and cutting your development costs. Based on BASF’s decades of experience in polyurethane research and production, the Forward AM range of advanced photopolymer resins and solutions delivers long-term UV stability and structural performance far superior to conventional photopolymers.

Ultracur3D® Photopolymer Product Portfolio

Rigid Line

Rigid, High-Performance Resins

Benefits at a Glance

- Top-notch materials for high-performance applications

- Excellent strength, stiffness and temperature resistance

- High accuracy and low shrinkage

Tough Line

Tough Multi-Purpose Resins

Benefits at a Glance

- Multi-purpose materials for a wide range of applications

- Superior toughness and impact resistance

Flexible/Elastomeric Line

Flexible and Elastomeric Resins

Benefits at a Glance

- Excellent performance for applications requiring elasticity and flexibility

- Very high softness and superior elongation at break

- Fast post-curing, no thermal treatment needed

Dental Line

Dental Resins

Benefits at a Glance

- Optimized properties for use in dental applications

- Cost-effective solutions for dental applications

Daylight Line

Daylight Resins

Benefits at a Glance

- Ideal for large-scale objects with extreme hardness

- High stiffness and flexibility for prototyping

Supplementary Line

Supplementary Products

Benefits at a Glance

- Supporting products to enable easier and more versatile processing

- Enabling a wide range of colors and finishes for printed parts

Brainstorm together

We’re looking forward to hearing from you! Contact us now and we’ll get in touch.

Ultracur3D® Photopolymer Works with Following Technologies

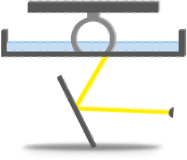

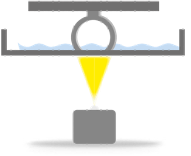

Stereolithography (SLA)

SLA offers extremely high accuracy with finely detailed features, either bottom-up or top-down. Being one of the most precise 3D printing techniques on the market, SLA can be used to create highly complex prototypes with a smooth surface finish.

- High surface finishing and accuracy

- Perfect for printing very large parts

Digital Light Processing (DLP)

Digital Light Processing provides excellent capabilities for 3D printing / Additive Manufacturing processes with an eye on efficiency. DLP is your go-to method when opting for a quick printing process without compromising on the quality of intricate parts.

- High productivity

- For larger and smaller parts

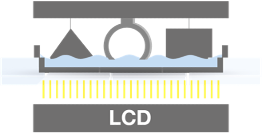

Liquid Crystal Display (LCD)

Liquid Crystal Display (LCD) provides the opportunity to replace low and medium series injection moulds with large parts. One of the biggest benefits of printing with Liquid Crystal Display (LCD) is to enable economic and large-scale production.

- Precise, high resolution prints

- Small and large scale 3D printing

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

Other Material Portfolios

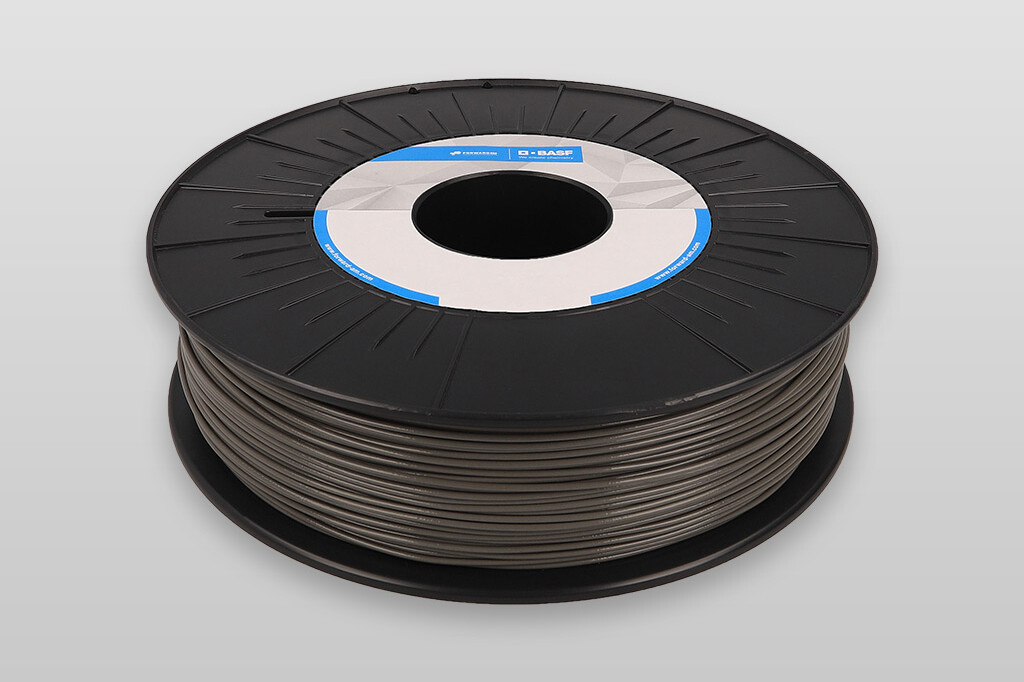

Metal Filaments

Discover our Stainless Steel Composite Ultrafuse® Metal Filaments for 3D Printers

Benefits at a Glance

- Easy and affordable metal 3D printing

- Fast material exchange and easy handling

- For all open-source FFF printers

- Wide range of post-processing options for green parts

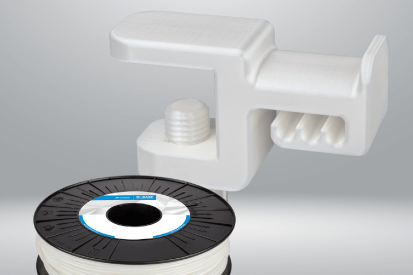

Ultrafuse® Filaments for Fused Filament Fabrication (FFF)

Discover one of the broadest portfolio’s for Fused Filament Fabrication

Ultrasint® Powders for Powder Bed Fusion (PBF)

Explore the Best Production-Grade Powders for 3D Printing