Chemical Smoothing

Optimize your parts to the fullest

Enhance the aesthetics and performance of your parts.

No strings attached!

Chemical Smoothing

What is Chemical Smoothing?

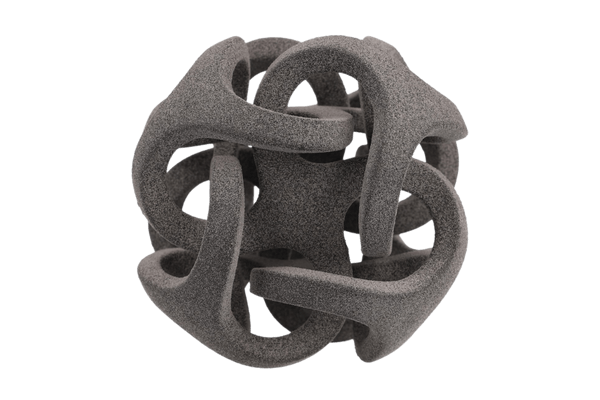

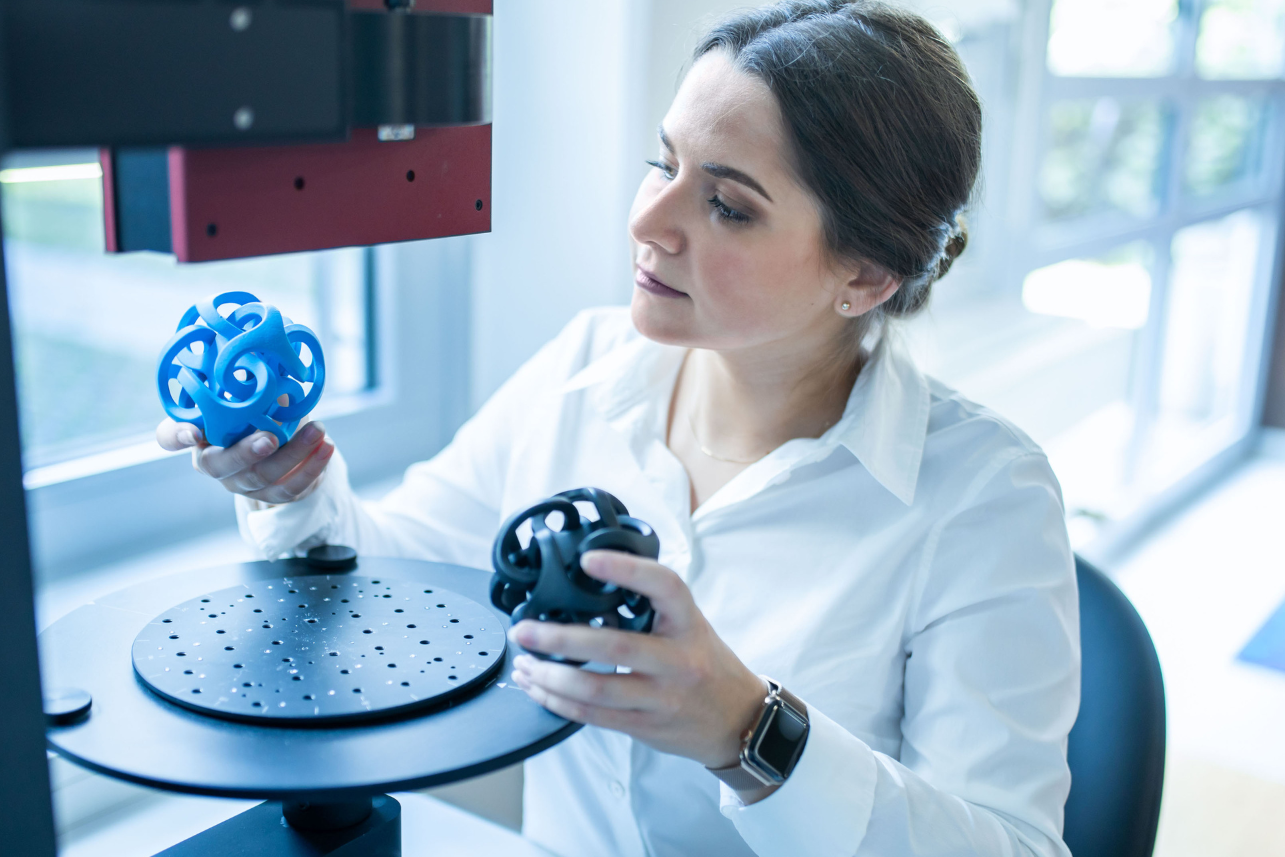

3D printed part surfaces exhibit rough, powdery and porous surfaces, limiting the use for various applications.

Chemical smoothing gives you a wealth of possibilities to enhance the appeal, durability, surface roughness, and overall quality of your 3D-printed part. It provides a sustainable post-processing solution to deliver repeatable and reproducible results for high-volume production.

How does chemical smoothing work?

During the process, a vaporized solvent is injected into the process chamber, where the vapor condenses on the surface of the part. A chemical reaction takes place between the solvent and the outer layers of the material, weakening the bonds of the polymer chains on the surface, resulting in a rearrangement to a more stable position. At the end of the process, the solvent is diffused, leaving a smooth and sealed surface. The accuracy and strength of the smoothing effect is controlled by controlled chamber conditions and exposure durations to achieve the desired surface finish.

Whitepaper

Polypropylene (PP) is a common and versatile polymer used for a variety of applications in automotive, aerospace, medical, and consumer industries. Learn more today.

With Additive Manufacturing, it can be challenging to produce parts with professional-grade surface finishes, making post-processing an essential step in the 3D printing process.

Discover other Services

Ultracur3D® Coatings

Discover the possibilities of coating your part with our Ultracur3D® Coat F+.

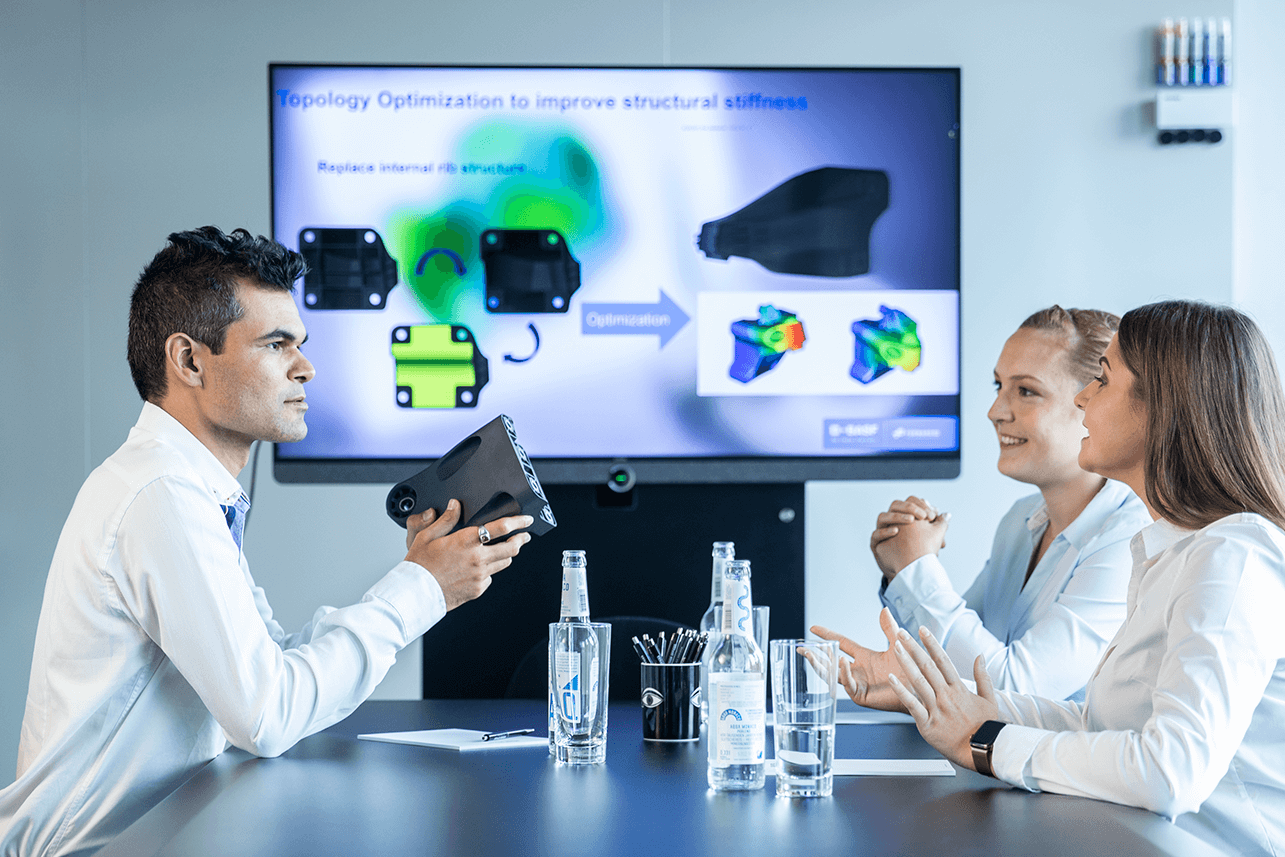

Ultrasim® 3D Consulting

Discover how simulation of part behavior and Design for AM increases the success rate of your 3D printed part.