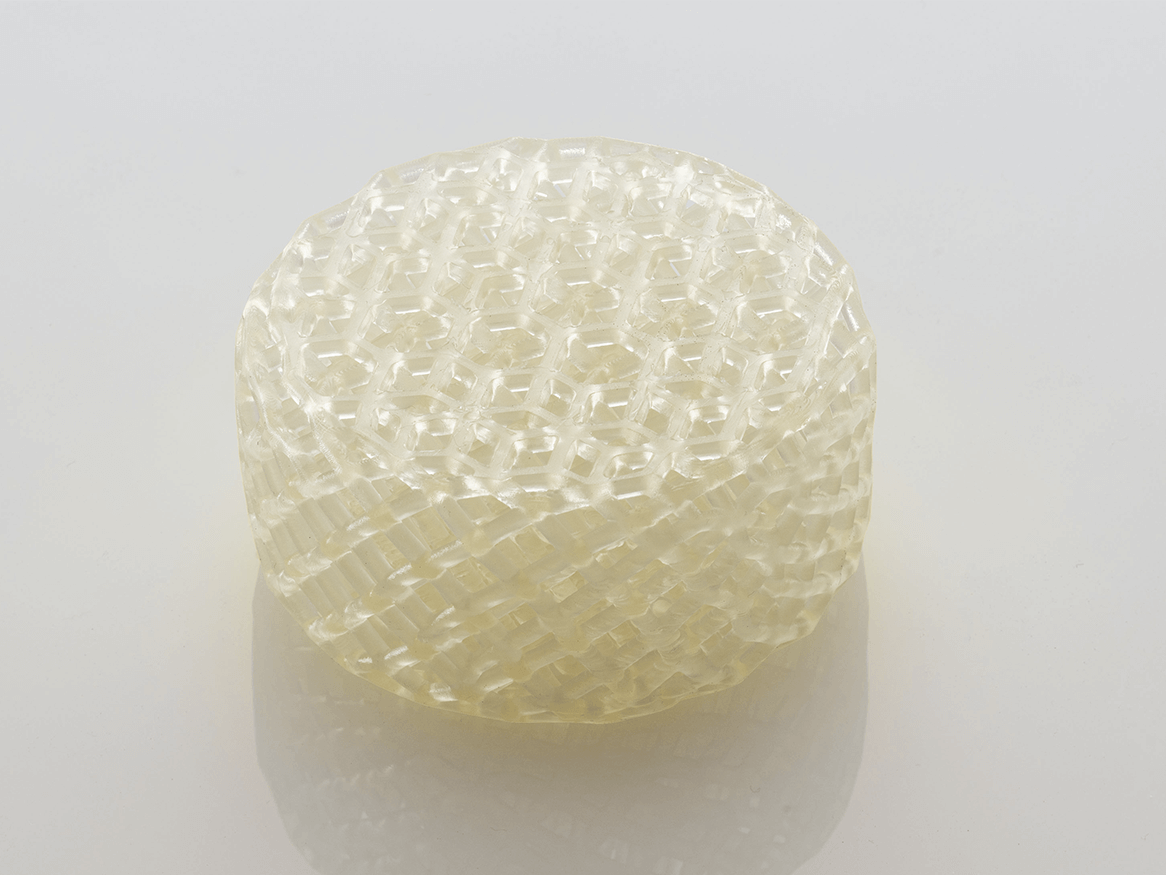

Ultracur3D® FL 300

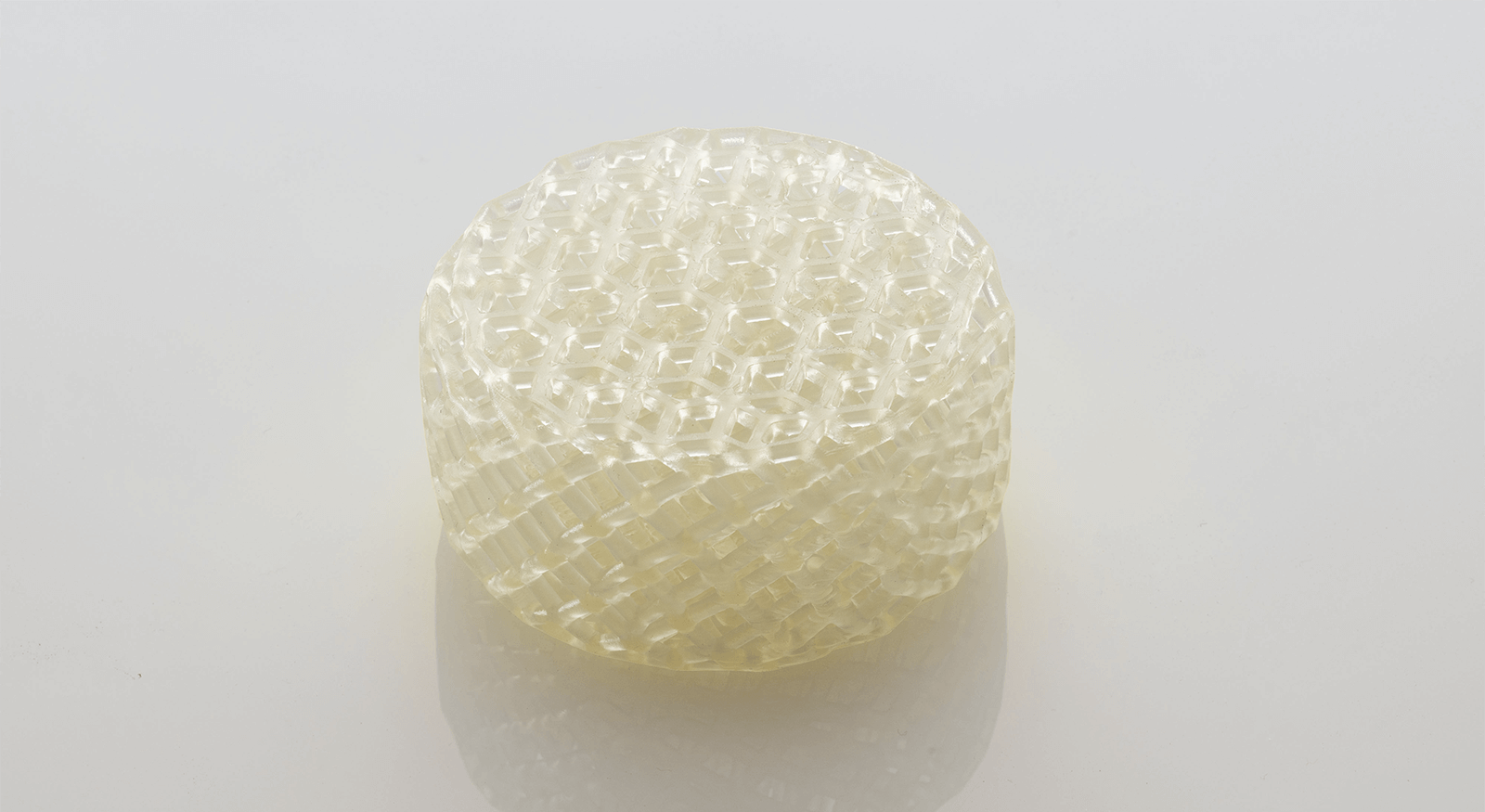

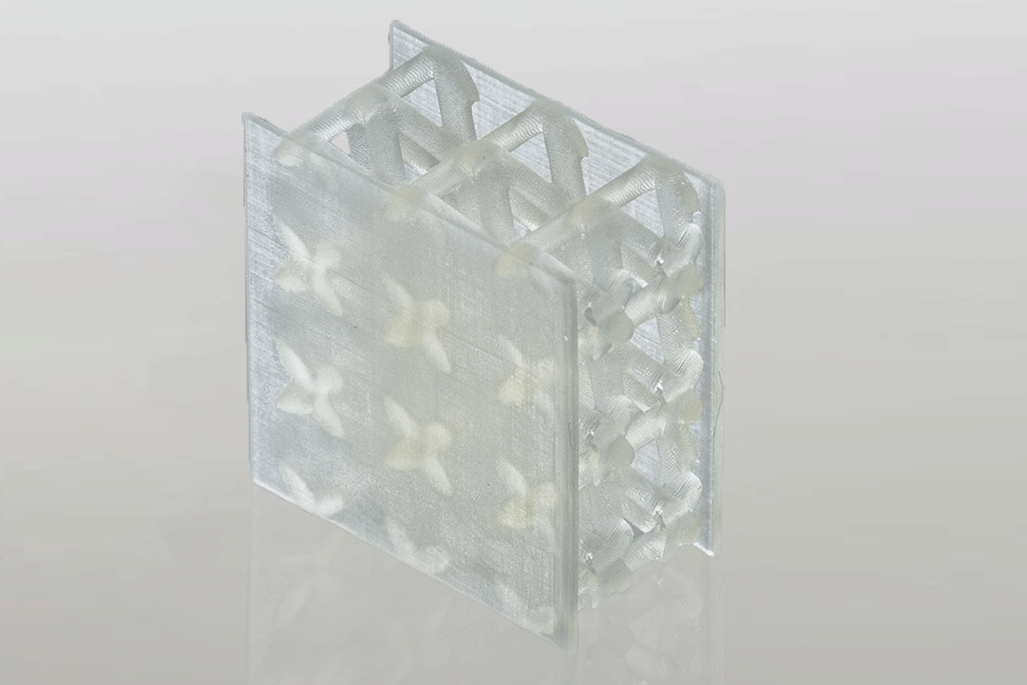

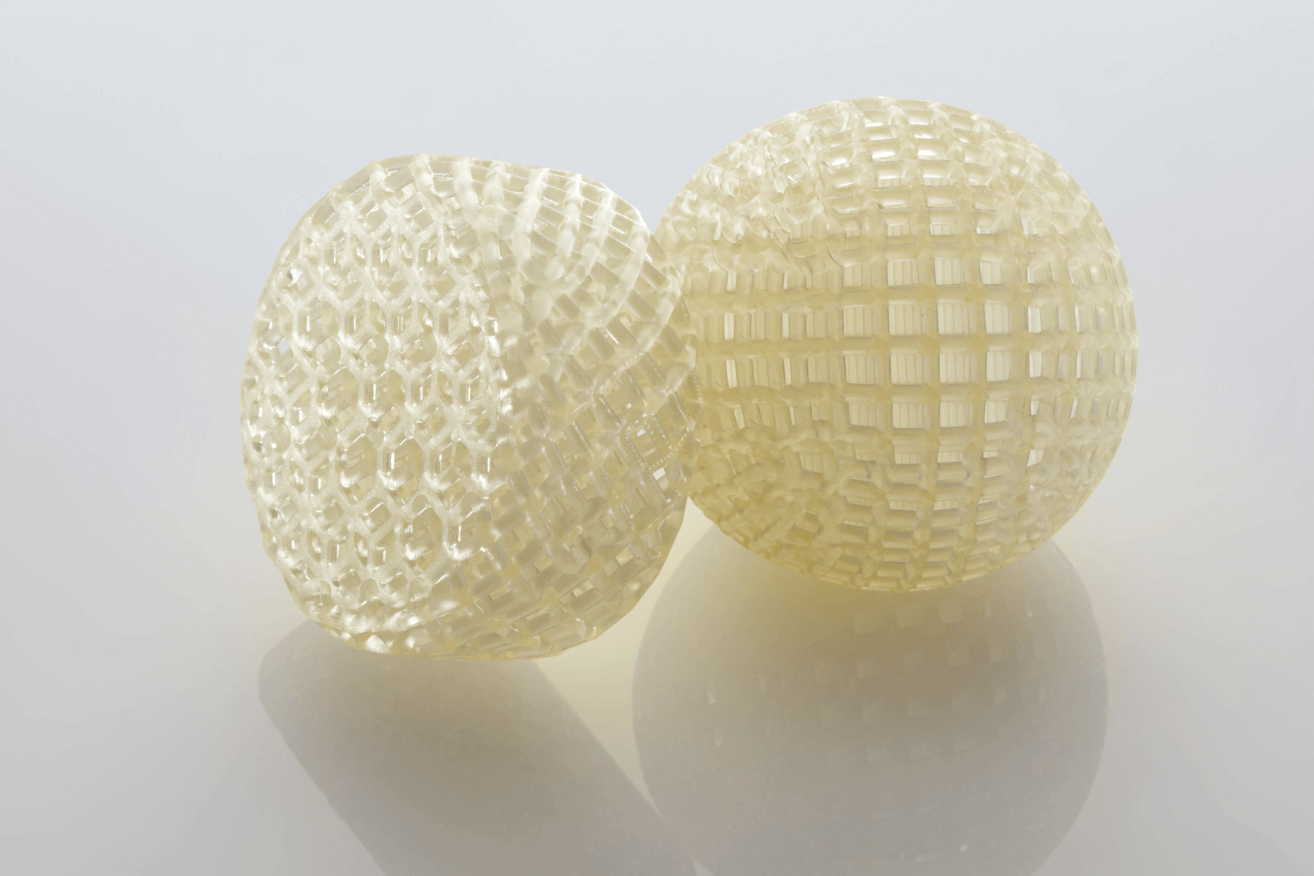

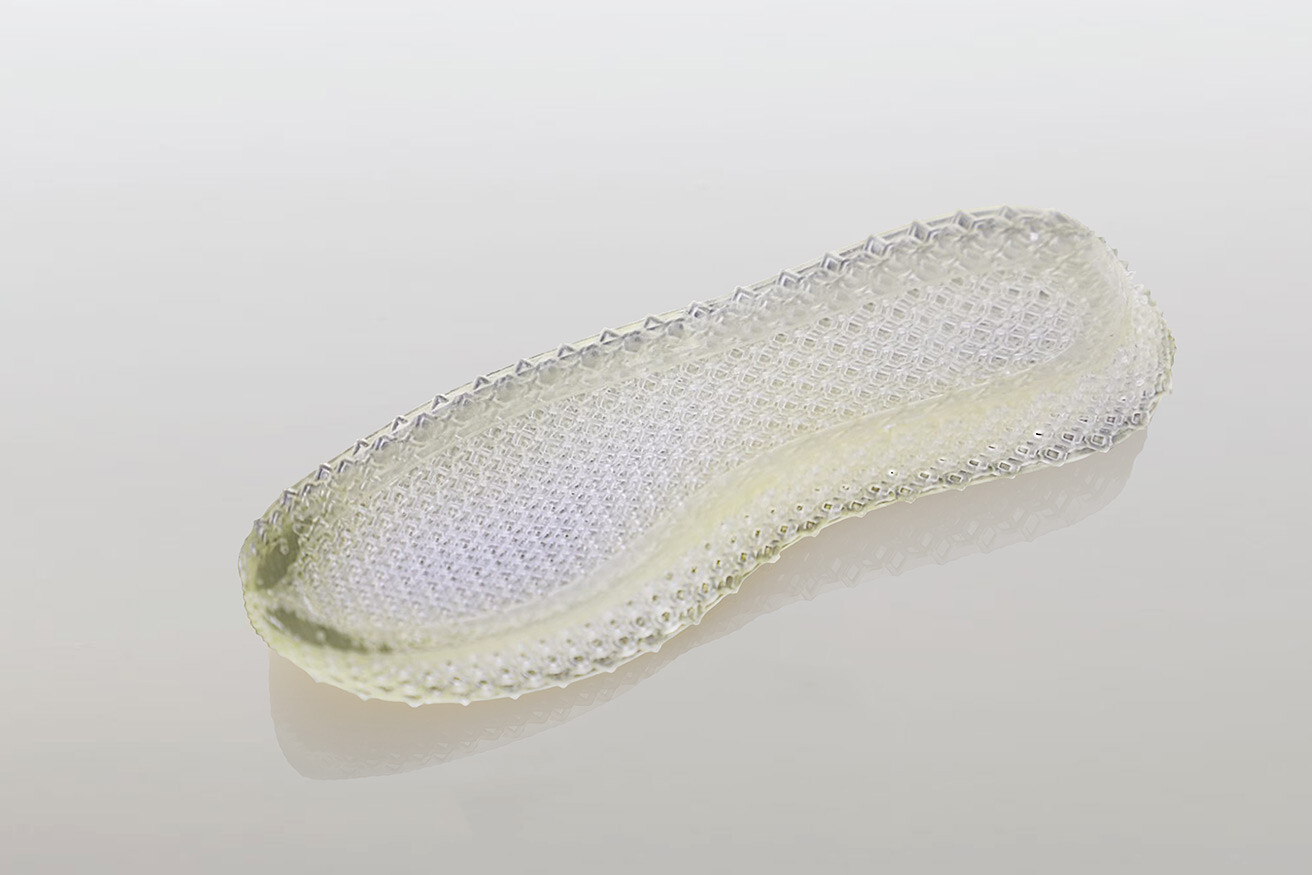

Flexible Resin with Superior Elongation and Softness (Shore 40 A)

Ultracur3D® FL 300 by Forward AM is a well-balanced reactive urethane photopolymer for flexible applications that delivers exceptional torsional flexibility with high tear strength. It provides very high softness (Shore 40 A), superior elongation at break, and consistent rebound.

Material Details

Benefits at a Glance

- Very low hardness (Shore 40 A)

- Superior elongation at break

Example Applications

- Footwear

- Prototyping

- Energy damping

- Cushioning pads

- Flexible grip

Material Properties

- Rebound resilience: 16 %

- Tear strength (Graves): 9 N/mm

- Elongation at break: 245 %

- Hardness: 40 A

Ultracur3D® FL 300 rebound behavior

- The Ultrasim® material model can also be used for simulating flexible materials

- Depending on the material’s energy dissipation the Ultrasim® material model can be adjusted to reflect the correct rebound behavior

Next Steps

Reference Links and Documents

Printing Workflows

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultracur3D® FL/EL Product Range Materials

Ultracur3D® FL 60

Flexible resin with optimum haptics and low hardness (Shore 60 A)

Benefits at a Glance

- Low hardness

(Shore 60 A) - Very good haptics

- Very stable clear-white color

Ultracur3D® EL 60

Flexible resin with quick elastic response and low hardness (Shore 75 A)

Benefits at a Glance

- Low hardness

(Shore 75 A) - Quick elastic response

- Easy to print, also very fine structures

Ultracur3D® EL 150

Flexible resin with optimum strength, rebound, and medium hardness (Shore 77 A)

Benefits at a Glance

- Medium hardness

(Shore 77 A) - Optimum combination of high strength, elongation at break, and rebound

Ultracur3D® EL 4000

Flexible resin with superior strength, rebound, and high hardness (Shore 90 A)

Benefits at a Glance

- High hardness

(Shore 90 A) - High green strength, ideal for printing intricate flexible parts

- Superior strength, rebound, and tear resistance