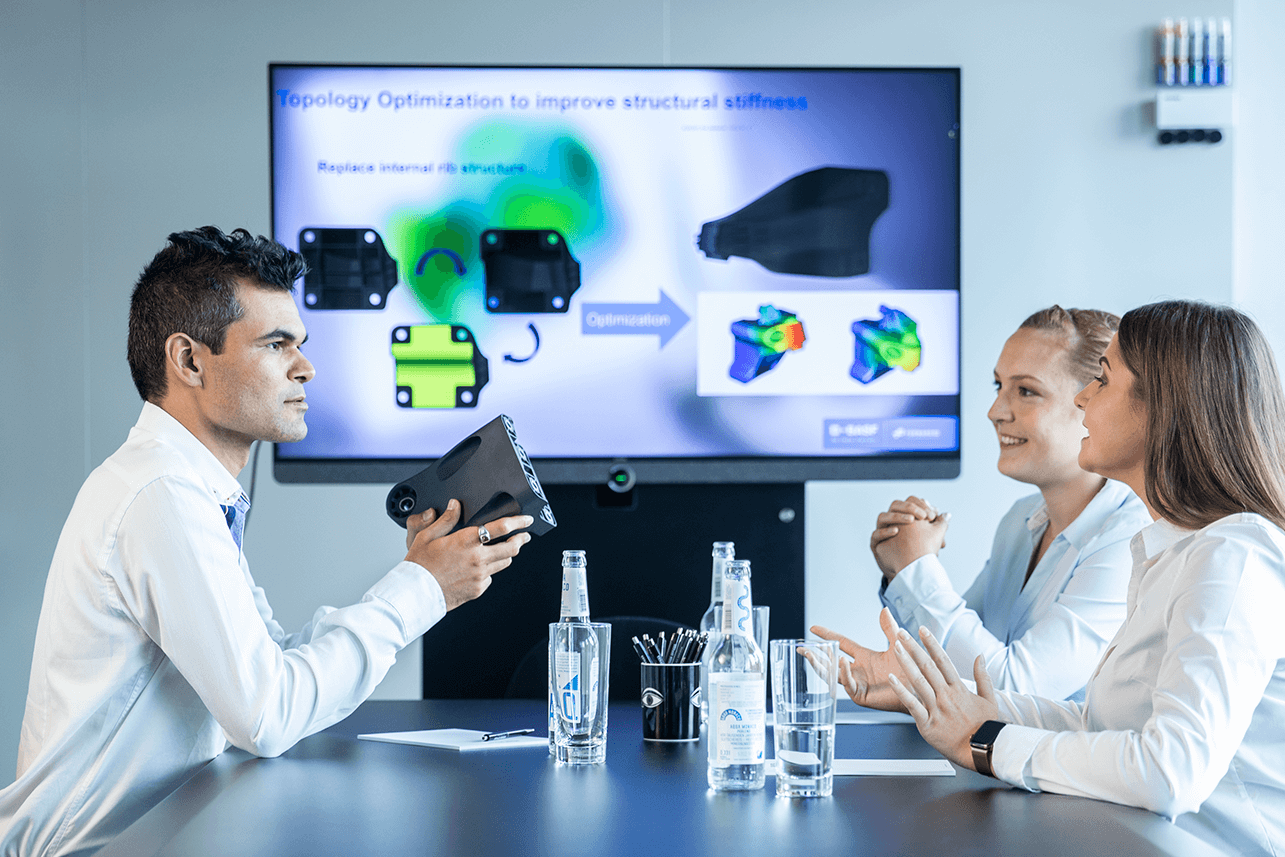

Ultrasim® 3D Simulation (FEA)

Be sure that your 3D printed design works

No strings attached!

Why Ultrasim® 3D Simulation (FEA)?

Ultrasim® 3D Simulation (FEA) helps speed up the engineering process, shortens the testing phase, and increases confidence in part performance using a digital twin of your part. BASF has more than 20 years of experience in simulation, coming from traditional injection molding and continuously developing for Additive Manufacturing.

Benefits at a Glance

- Be sure that your design work

- 3D printing specific material data & modeling

- Quicker development cycles

- Optimization of 3D printed design

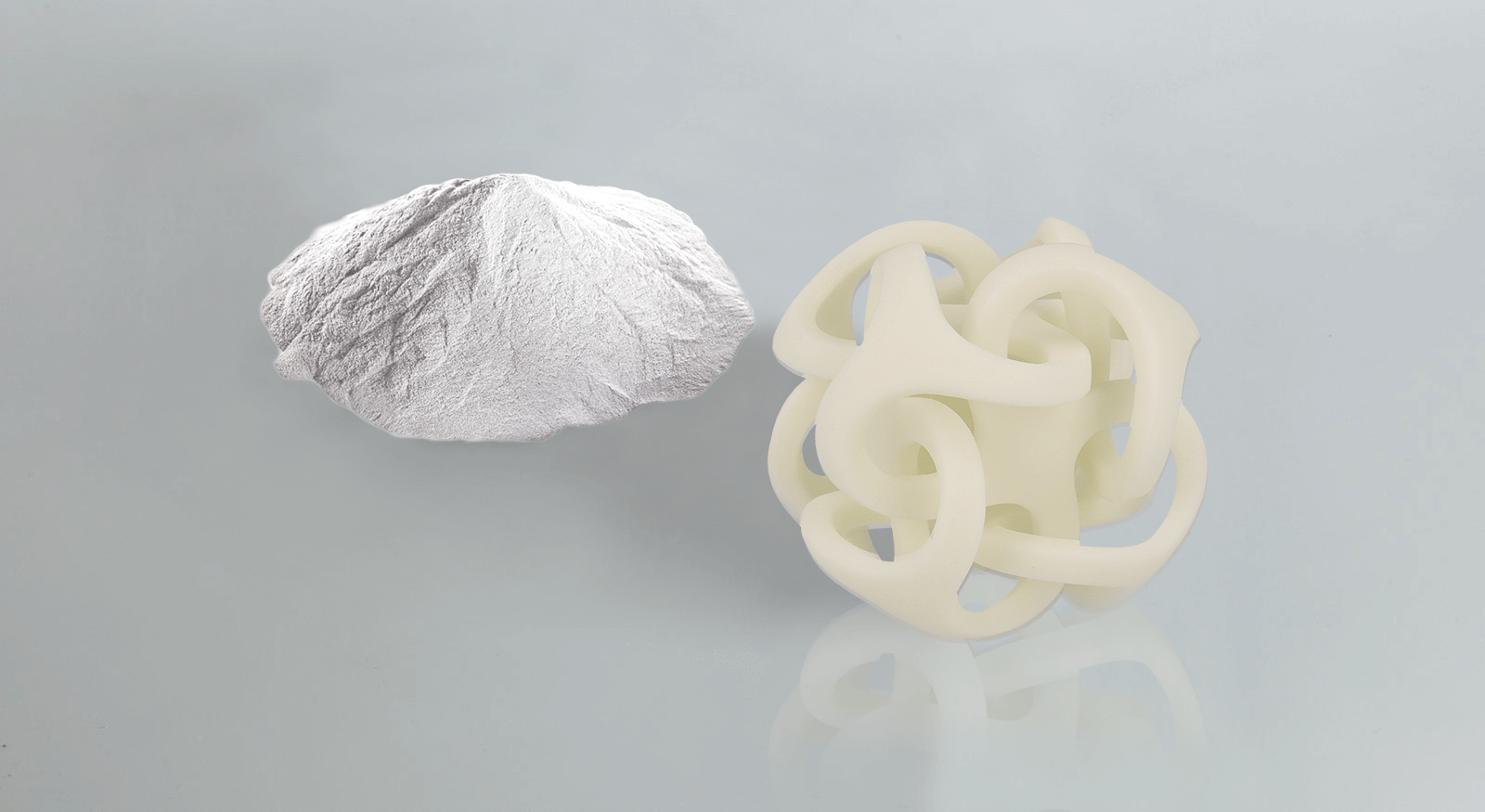

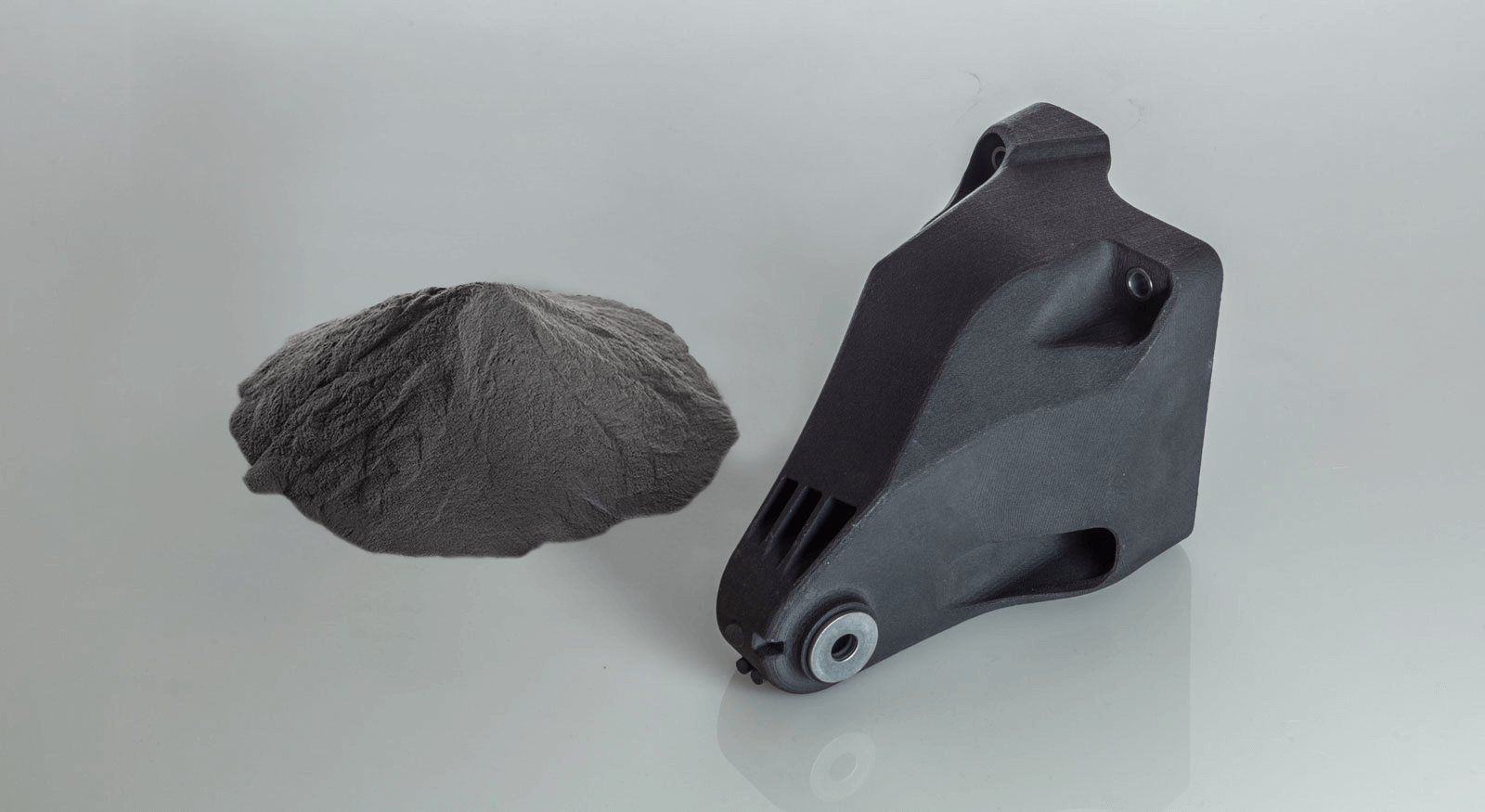

Available AM Technologies

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

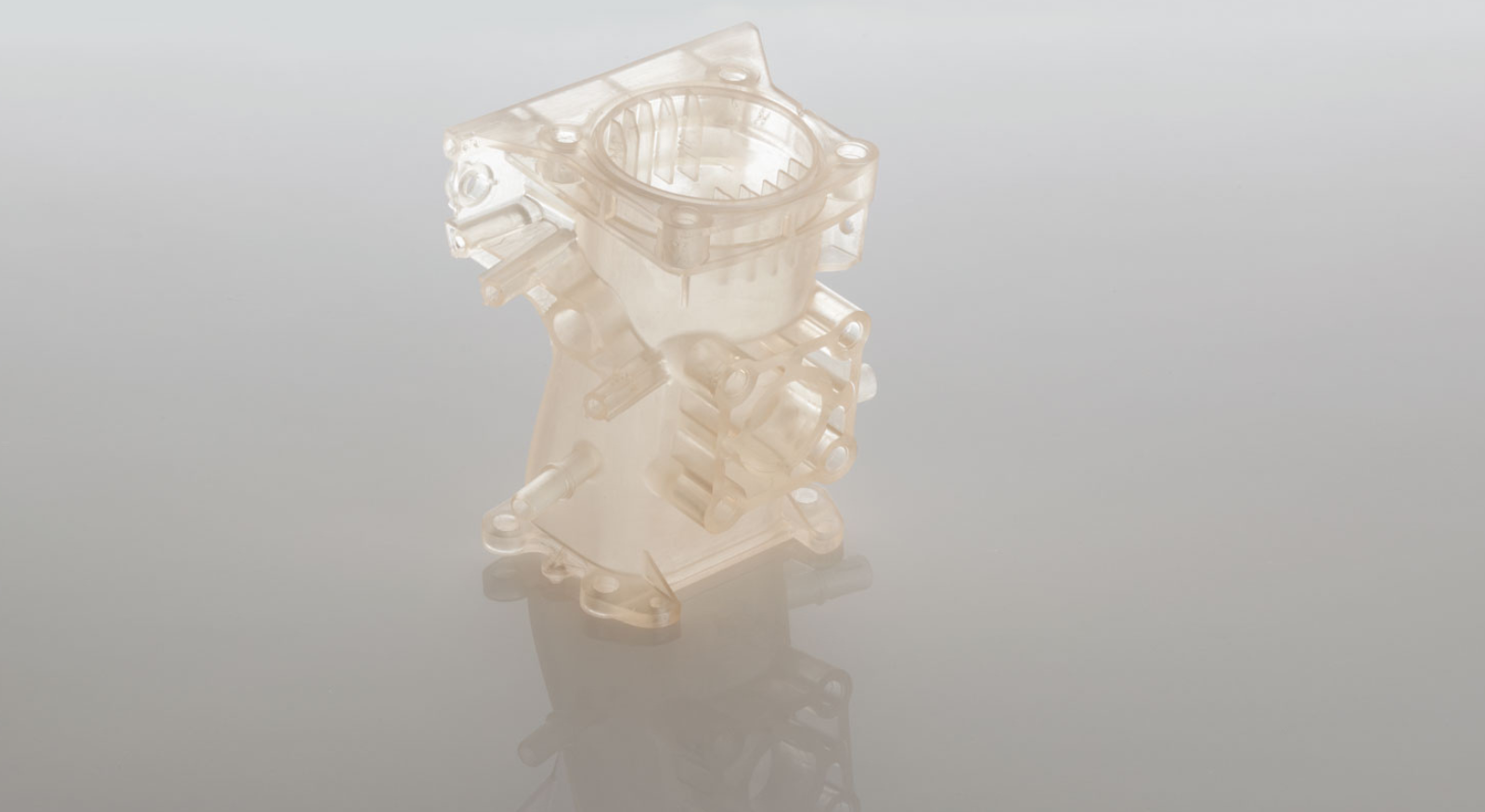

- Digital Light Processing (DLP)

- Liquid Crystal Display (LCD)

Ultrasim® 3D Simulation (FEA)

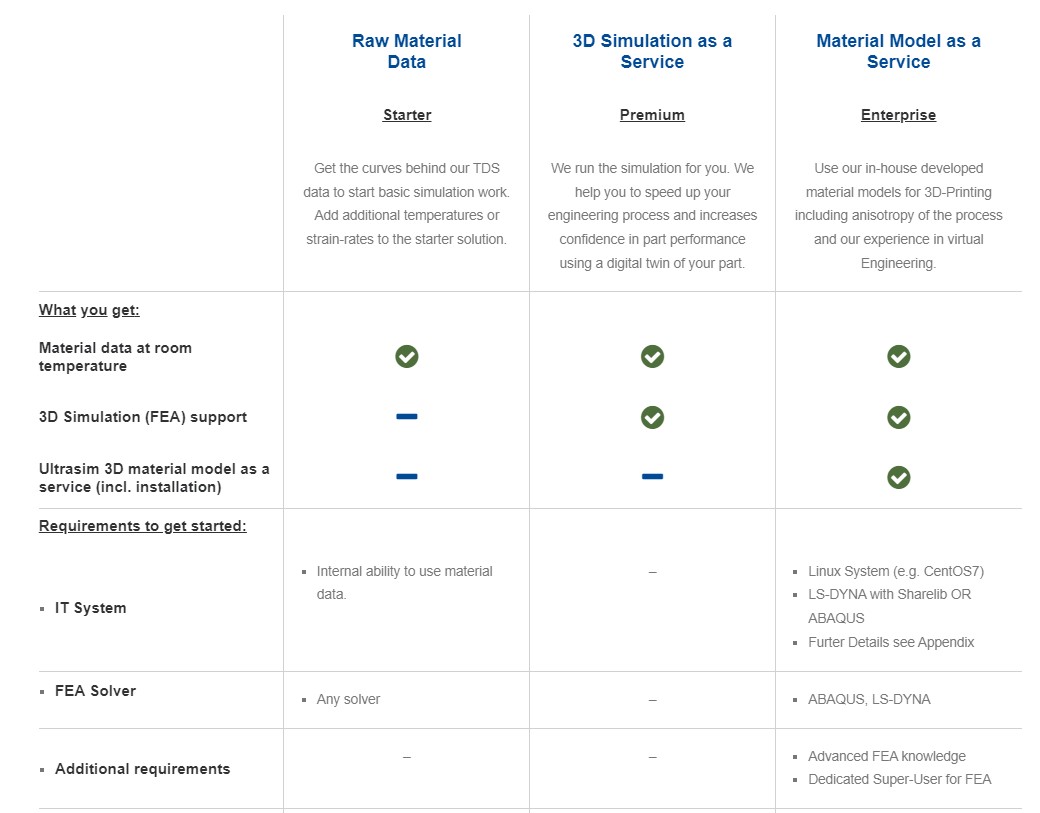

We offer 3 different options – from starter to expert:

Raw MaterialData

Starter

Get the curves behind our TDS data to start basic simulation work. Add additional temperatures or strain-rates to the starter solution.

3D Simulation as a Service

Premium

We run the simulation for you. We help you to speed up your engineering process and increases confidence in part performance using a digital twin of your part.

Material Model as a Service

Enterprise

Use our in-house developed material models for 3D-Printing including anisotropy of the process and our experience in virtual Engineering.

What you get:

Material data at room temperature

3D Simulation (FEA) support

Ultrasim 3D material model as a service (incl. installation)

Requirements to get started:

-

IT System

- Internal ability to use material data.

–

- Linux System (e.g. CentOS7)

- LS-DYNA with Sharelib OR ABAQUS

- Furter Details see Appendix

-

FEA Solver

- Any solver

–

- ABAQUS, LS-DYNA

-

Additional requirements

–

–

- Advanced FEA knowledge

- Dedicated Super-User for FEA

Get you Add-on:

- Material data at additional temperatures and strain rates

- Material data at additional temperatures and strain rates

- Material data at additional temperatures and strain rates

What we need from you:

- Material of interest (see table)

- 1 hour of your time to understand your goal and derive the data set you need.

- 1 hour of your time to understand your problem and derive a solution concept.

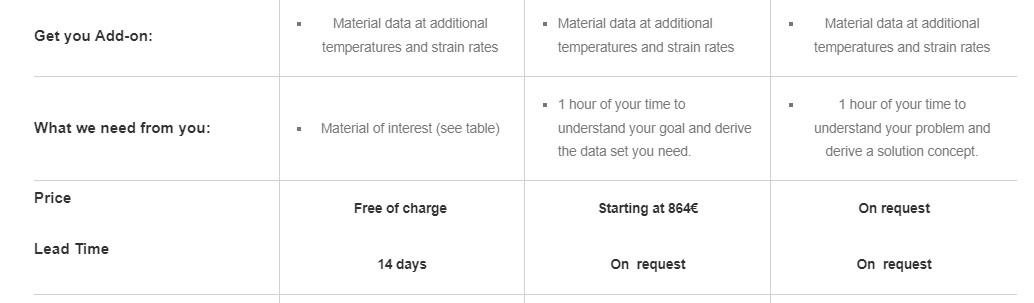

Price

Lead Time

On request

14 days

On request

On request

On request

On request

Ultrasim® 3D Simulation (FEA)

We offer 3 different options – from starter to expert:

Real-Life Applications

Use Cases

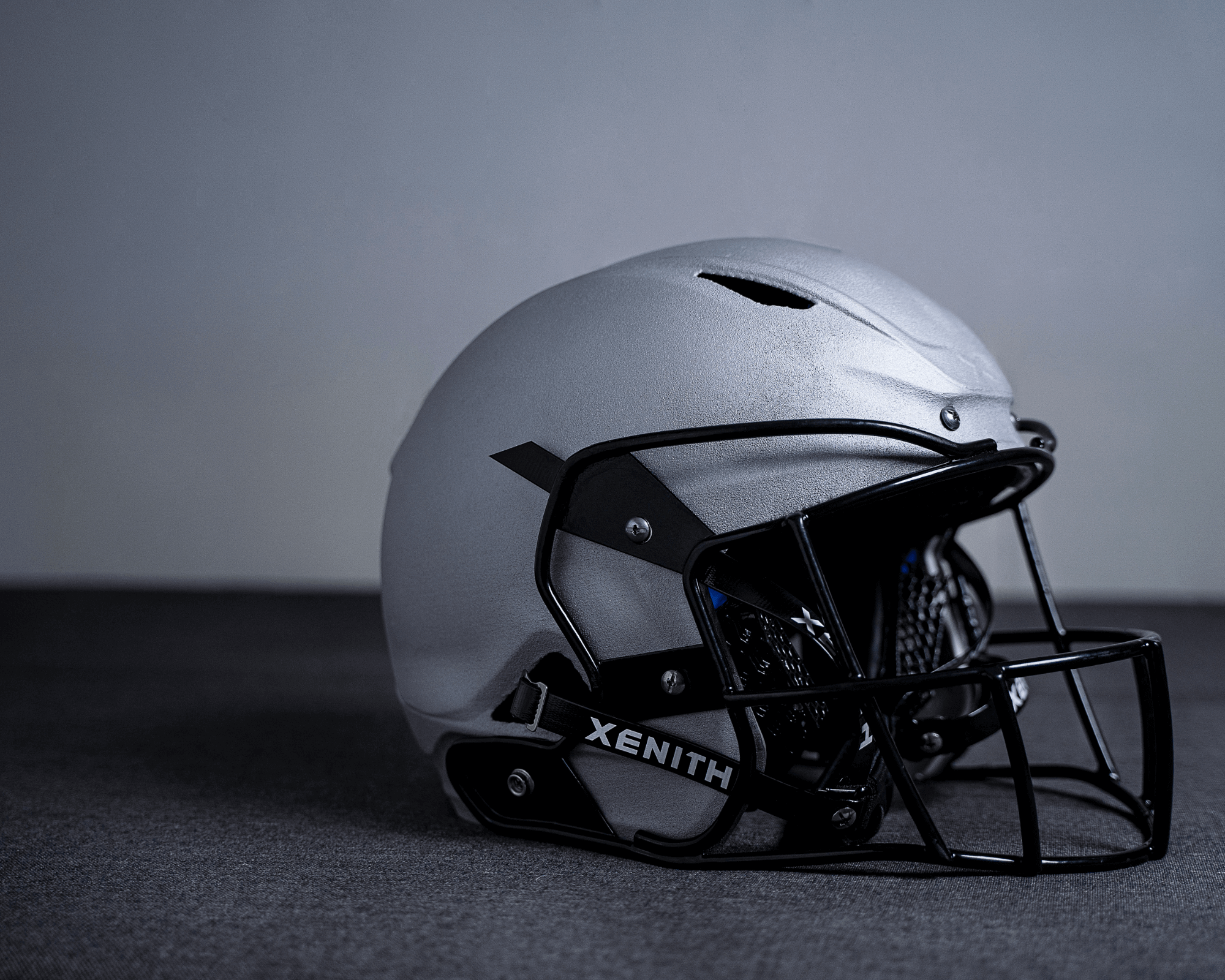

Protective Helmets

In baseball, hockey, football and all other sports, head trauma through collision is an omnipresent risk for all athletes. And it doesn’t stop with…

Protective Pads

When doing sports, rather than worry about the risk of injury we want to focus on our performance and the enjoyment it gives us. With rising consumer…

Webinars:

Full potential for 3D Printing Materials enabled by Ultrasim® 3D Services

The next generation of Football Helmets. Learn more about how BASF 3D printing materials + services result in safer Football Helmets.

Protective Gear - What's up in 3D Printing?

What are the benefits of using AM to produce protective gear? Watch the webinar and learn more about the usage of lattice structures for impact and shock absorption.

How Lattices Drive Applications in AM

Watch the recording of our expert session at Formnext and learn how lattices revolutionize the production of customized components that require cushioning or shock absorption.

Ultrasim® 3D Simulation Material Availability

Discover other Ultrasim® 3D Services

Ultrasim® 3D Cost Analysis (TCO)

Understand the cost structure of your 3D printed part, what drives costs, and how this compares to other AM technologies.

Ultrasim® 3D Consulting

Discover how simulation of part behavior and Design for AM increases the success rate of your 3D printed part.

Ultrasim® 3D Lattice Design

Compliant lattice structures open exciting product design possibilities that would be previously considered ‘unmakeable. Benefit from better aeration, weight reduction, and increased comfort.