Protective Pads

Forward AM Changes the Game with Sports Protection

When doing sports, rather than worry about the risk of injury we want to focus on our performance and the enjoyment it gives us.

Project Breakdown

Industry

Consumer Goods

Product

Protective Pads

Why Forward AM?

High-performance AM materials plus deep simulation expertise

Forward AM materials used

Ultrasint® TPU01, Ultrasim®, Ultracur3D® Coat F+

The result

Protective pads with lattice structures, enabling lightweight sports protection and fast, cost-efficient design cycles thanks to virtual engineering

Challenge: Play smart, play safe

With rising consumer awareness of health and fitness and the general trend towards a more active lifestyle, it comes as no surprise that protective sports equipment is experiencing a strong increase in demand. More and more pro athletes and enthusiasts are keen to invest in their safety while doing what they love. In addition, safety regulations in various sports are getting tighter, another factor boosting rapid growth in protective sports equipment sales. Alongside helmets and headgear, protective pads are key items that can be applied to protect almost every part of the human body. They’re used in gridiron football, rugby, soccer and hockey – all notoriously prone to on-field injury. We can add motorcycling, mountain biking and a host of indoor sports to the high-risk list. But until now, protective pads have generally been bulky, heavy – and let’s face it, sweaty – items that mostly get in the way of sports enjoyment.

Solution: Unlocking the power of the lattice – with virtual engineering and FEA-simulation

So how does Additive Manufacturing come into play?

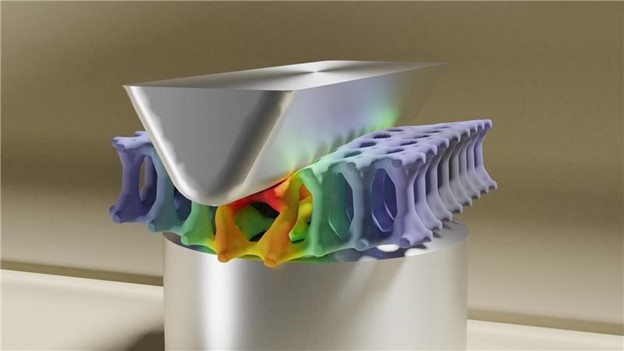

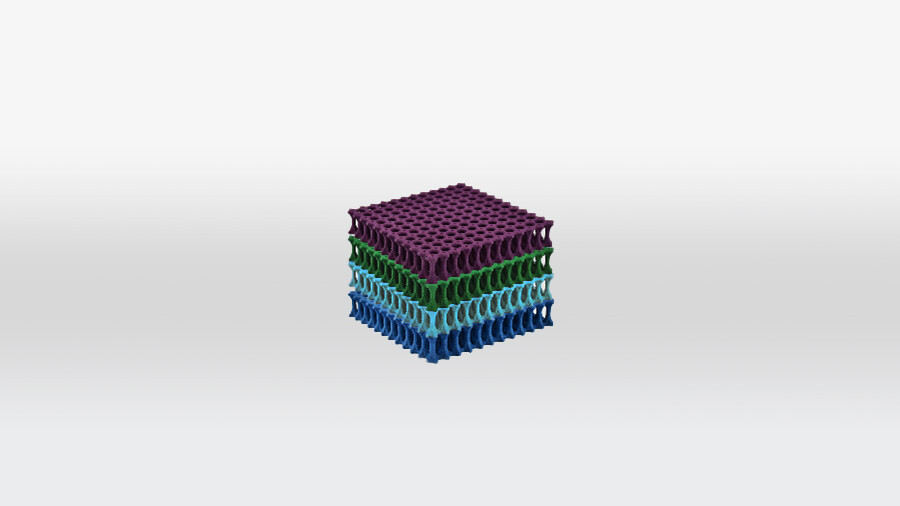

There is a specific material structure that is the perfect match for protective pad design – and can only be achieved through Additive Manufacturing: the lattice. What makes them unique is how they distribute materials into design elements. They form an ideal impact-cushioning structure comprised of node and strut micro-architectures. This format drastically reduces weight, delivers excellent structural integrity, and offers advantages of critical performance characteristics in protective sports gear applications:

- Ventilation

- Local control of impact absorption

- Individualization

- Strength-to-weight balance

- New design possibilities

To keep a long but fascinating story short: Using lattices fulfills all the vital requirements of modern protective sports equipment, i.e. an outstanding strength-to-weight ratio, superb control on impact absorption, complemented by a featherweight open design enabling excellent passive climate control.

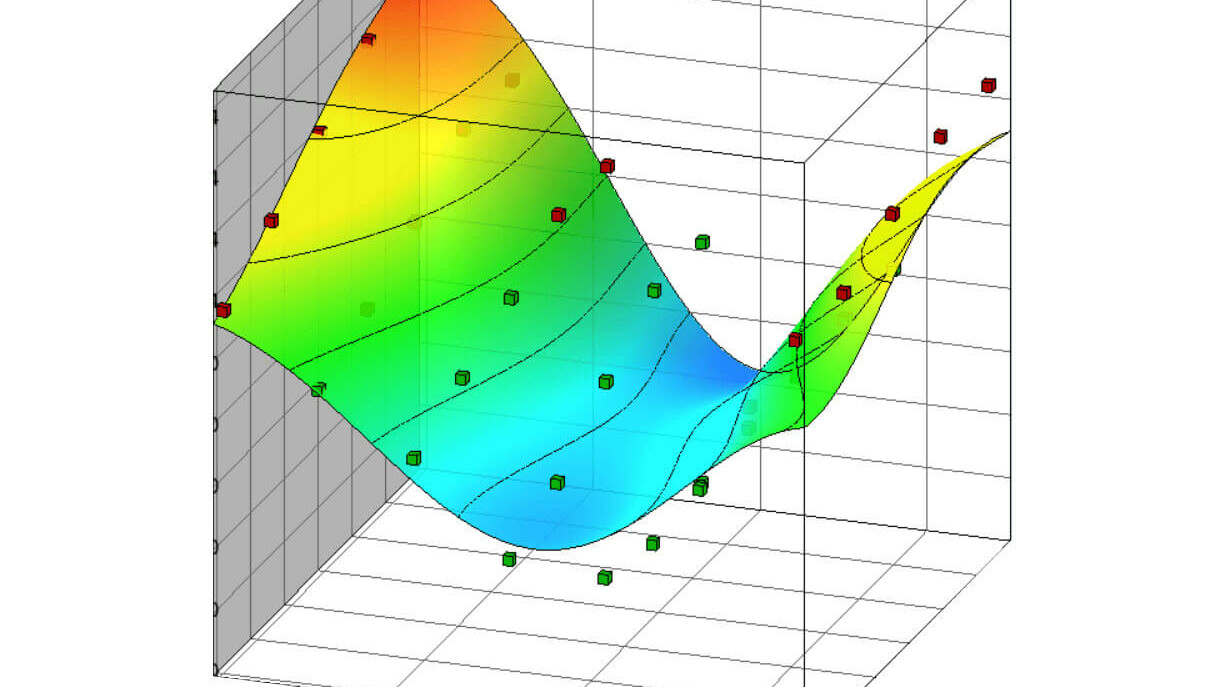

Until now, identifying and creating the right lattice structure for an application fulfilling impact requirements meant time- and cost-intensive “design-print-test-redesign” iterations. Ultrasim®, the virtual engineering suite by BASF, overcomes this challenge and is establishing itself as the industry 3D optimization service of choice. A powerful digital optimization workflow, Ultrasim® enables the smart search for the optimal lattice geometry to fulfil each application’s unique mechanical performance requirements. By accelerating design and test iterations, Ultrasim® cuts concept-to-component time, unlocking major cost and material savings. Topping it off, it also identifies the optimal balance of component performance and weight – especially relevant in protective sports equipment. Interested in finding out more about our Lattice Engineering offer? Head over here.

“With our digital geometry-design services we enable a smart search for the optimal lattice geometry – always tailored to the unique mechanical performance requirements of each customer’s component and project. With Virtual Engineering, we accompany our customers from first idea to living conceptual computer model to finished part – making sure to identify and manufacture the ideal lattice for the best possible result.”

Andreas Wüst, Head of Dynamic Structural Analysis, BASF

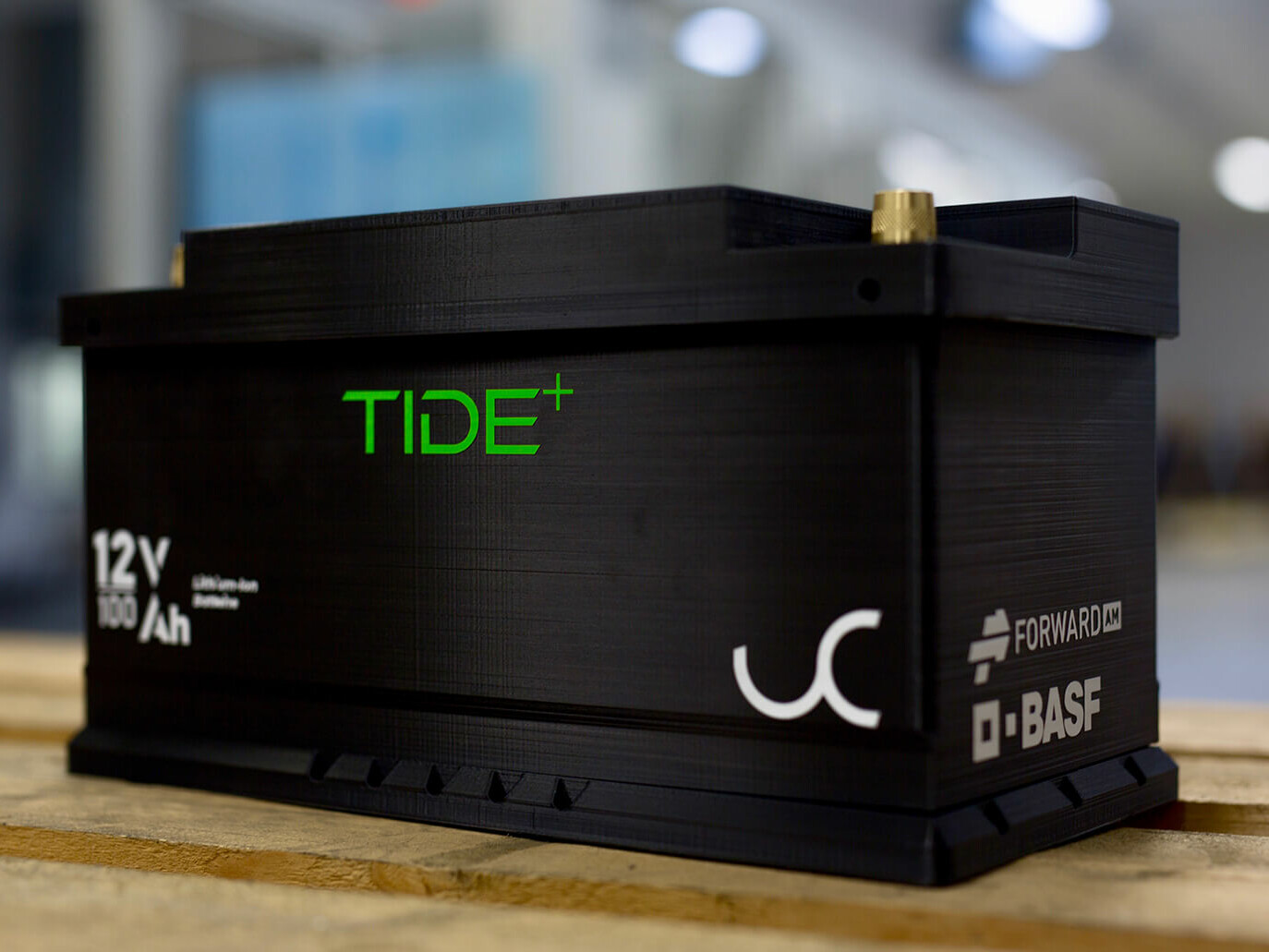

In terms of the right 3D printing material, Forward AM’s Ultrasint® TPU01 and 88A are the ideal matches for lattice applications. These thermoplastic polyurethane powders’ high flexibility combined with the high stiffness make them perfectly suited to printing highly detailed lattice structures. With both materials having successfully passed skin sensitization and cytotoxicity tests in accordance with ISO 10993-10 and ISO 10993-5, they can be used in applications close to the human body with complete peace of mind.

Simulation always needs the real-life validation. Thus, Forward AM’s specialists sent the first completely digitally engineered lattice structure for a protective pad to TÜV Süd as a printed part for exhaustive testing: It successfully passed ISO1621-2 with flying colors under real-world conditions. From digital file straight to successfully passed tests at TÜV Süd – spot landing! This European Standard specifies and regulates the minimum coverage to be provided by back protectors as worn by motorcyclists in normal road traffic.

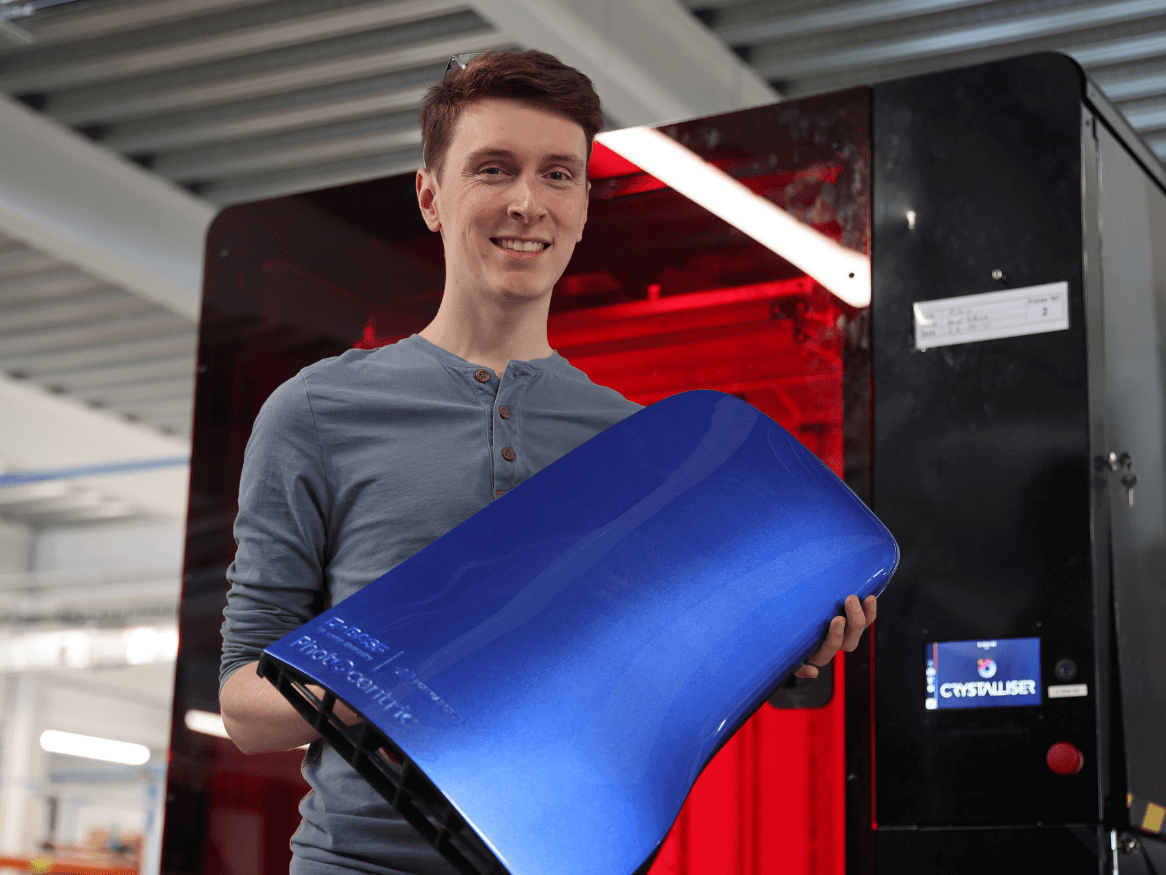

As protective pads are clearly visible, we don’t stop once the part is printed. By adding our Ultracur3D® Coat F, the pads gain an enhanced visual appearance as well as functional improvements. This flexible coating is specially developed to give TPU parts a colorful touch – and like our TPU, it has successfully passed both skin contact and cytotoxicity tests. With convincing adhesion and outstanding elasticity, it’s the perfect fit for applications such as lattice structures, additionally increasing their abrasion resistance. The successfully completed Rossflex test of 100,000 bending cycles proves its durability and strength, even in demanding applications like sports equipment.

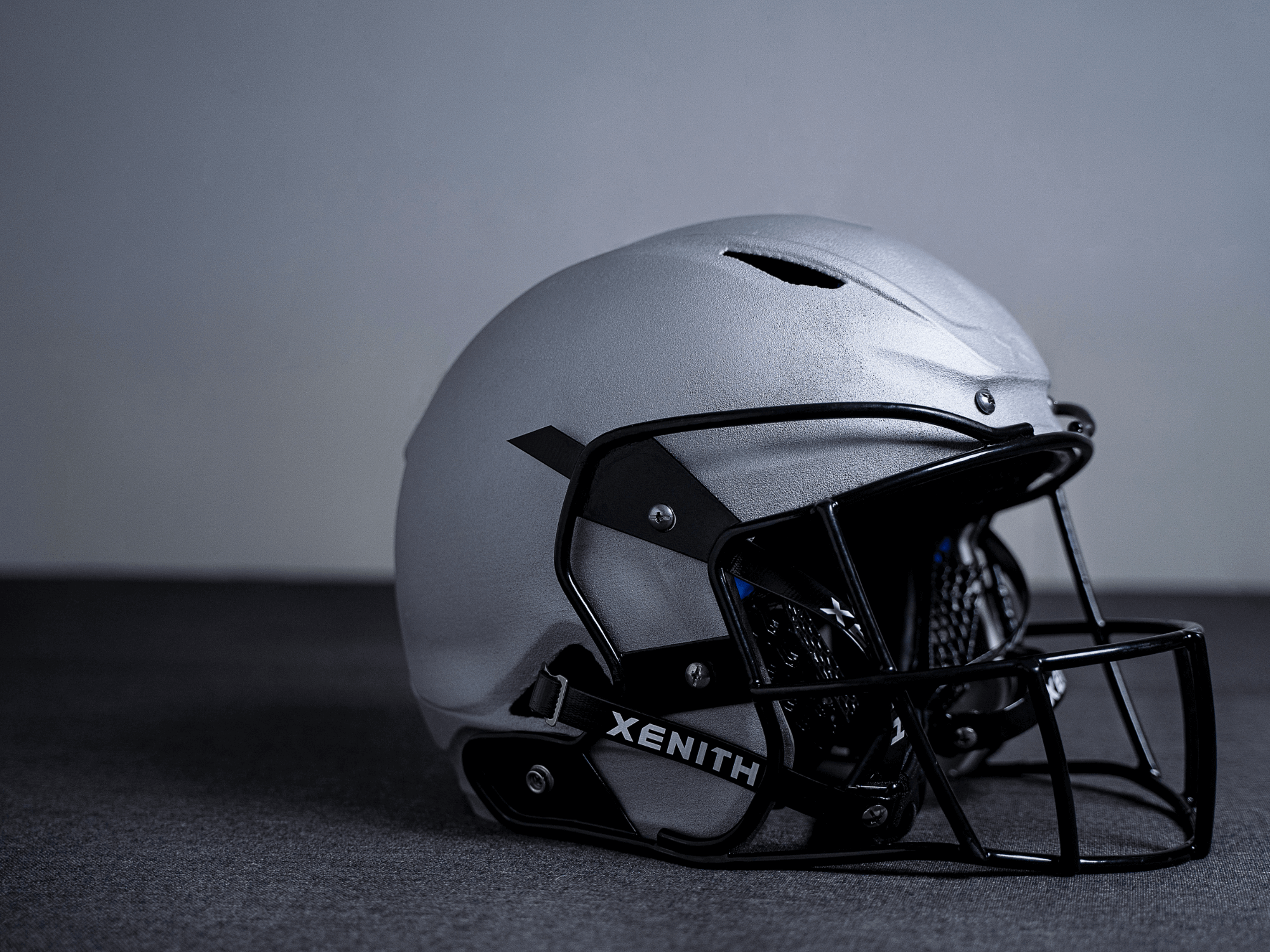

“The Ultrasim® capabilities of Forward AM Team are second to none – deep knowledge of lattice performance, durability and design for AM. When provided a design goal this workflow can be applied to filter the number of design options and converge on a physical product to meet this goal in a very time efficient manner. This is a game-changer to solving the very complex problems with virtually an infinite number of possible solutions!“

Dr. Ron Jadischke, Chief Engineer, Xenith.

And for the finishing touch, Forward AM goes beyond the standard colors to offer customized color shades for individual requirements – making it easy for sports teams and companies to express their identity or branding. Currently, the color shades comprise amongst others – Pure Red, Grass Green, Purple Violet, Metallic Blue, Metallic Silver, Light Blue and Canola Yellow.

Share this page

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!