Leak Test Seals Exceed Performance Expectations

State-of-the-art materials and advanced 3D printing technologies provide strength, accuracy and reduced production costs

Valiant TMS – a global company specializing in welding and joining, automated assembly and test, industrial parts washers, final assembly, and material handling systems – is producing Leak Test Seals utilizing BASF Forward AM’s Ultracur3D® ST 45 B resin in combination with the Stratasys Origin® One P3TM DLP printer.

Project Breakdown

Industry & Application

Automotive

Product

Ultracur3D® ST 45 B

Partner

Valiant TMS

Technology

DLP

Why Forward AM?

Material expertise ensured great results in finish quality while also reducing the manufacturing cost.

Valiant TMS is a global company with over 1,500 employees working at 20 facilities spread throughout 11 countries. They design, build and integrate intelligent automation solutions that leverage new technologies to create smart and sustainable factories for the world’s leading companies.

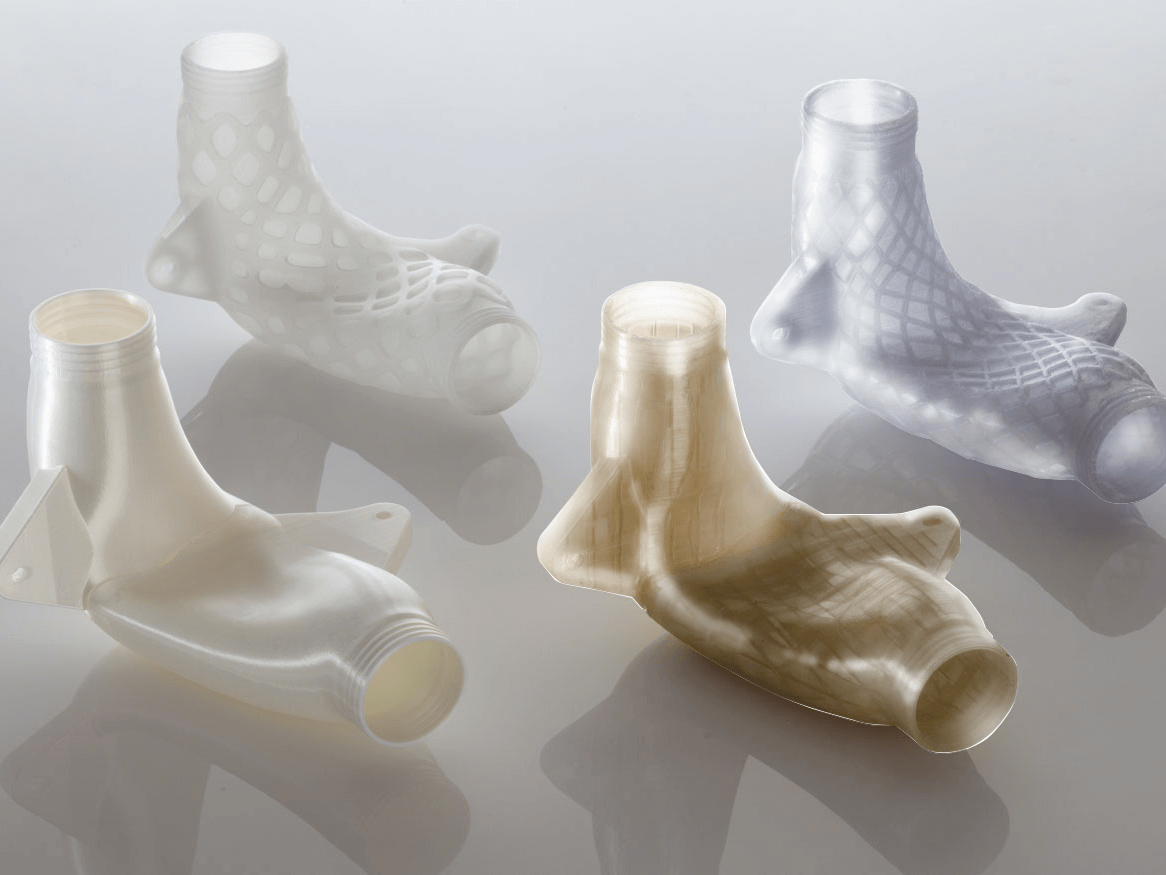

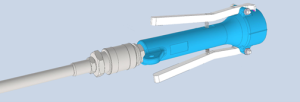

Leak Test Seals are used during the end-of-line test of batteries to determine whether the coolant loop on the battery pack is properly sealed. The seal must be capable of adhering completely to the many different geometries as well as in areas of very low clearance. This makes them very challenging to manufacture using traditional machining methods. Through the utilization of BASF Forward AM’s Ultracur3D® ST 45 B resin, Valiant TMS was able to achieve great results in finish quality of the seal while also reducing the manufacturing cost.

The Challenge

Many of the sealing areas on the battery are plastic electrical connectors, which can be easily damaged. Therefore, it is crucial that the seals are both non-conductive and produced with materials that will not scratch or damage the connectors.

Previous seals were made with machined aluminum or Delrin bodies, but these seals were bulky and not ergonomic while also carrying the potential of damaging the electrical connectors. An additional difficulty was machining the O-ring grooves in these seals. Originally Valiant TMS tried to print the sealing gasket material, but the dimensions were too small for the material so a sealing O-ring was adopted instead.

The Solution

During the development of the Leak Test Seals, Valiant TMS was looking to find an advanced material for the application as well as a reliable and trusted technology to produce it. The goals were to maximize part strength, improve part quality and surface finish, optimize production time, improve part accuracy and reduce costs.

By collaborating with Forward AM, Valiant TMS was able to find a best-in-class material which is fully compatible with commercial available DLP and LCD printers in the market. Ultracur3D® ST 45 B material, a tough multi-purpose resin with optimum toughness and processing speed, was identified as the ideal choice for the requirements. This innovative material is very well-suited for 3D printing high-performance, functional parts requiring high-accuracy and mechanical strength. It also ensures very fast printing and outstanding surface finishing.

The material properties of Ultracur3D® ST 45 B become isotropic, which improves part strength while also offering a smooth surface finish that is superior to other manufacturing technologies. Additionally, the accuracy of the part is also much higher, meaning secondary post-processing may be eliminated. Printing the tools with Ultracur3D® ST 45 B allowed Valiant TMS to make the Leak Test Seals smaller and fit in the restricted space as well as making the assembly process easier.

The Result

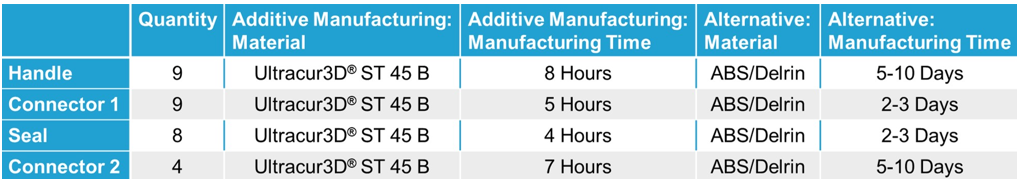

Through the utilization of Additive Manufacturing, the production time required was substantially lower than that of traditional manufacturing. 3D printing also enabled Valiant TMS to lower the cost by 150% when compared to alternative manufacturing methods. The table below illustrates the significant changes in manufacturing time of parts printed with Ultracur3D® ST 45 B compared to alternative manufacturing methods assuming immediate availability of each technology.

The table refers to following parts:

Producing the parts in-house is clearly beneficial for Valiant TMS as the tools can be produced on demand and with significantly lower manufacturing time.

“It’s clear that the way we use additive manufacturing in our company draws the attention of the OEM’s and it shows that we have a story to tell in the AM industry. Working closely with partners like BASF Forward AM, we can create case studies that can provide other companies a recipe for success as they begin their AM journey. Our success leads to OEM’s success and eventually provides a better product to the market.”

Adrian Pop, Additive Manufacturing Leader at Valiant TMS

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!