Ultrafuse® 17-4 PH

The Filament Enabling Stainless Steel Parts for Applications that Require High Hardness and Mechanical Strength

Ultrafuse® 17-4 PH is a filament for the production of metal components in 17-4 stainless steel on standard Fused Filament Fabrication (FFF) printers.

Material Details

- Product Leaflet

- Technical Data Sheet: EN, FR, ES, DE, ZH

- User Guidelines

- Process Guidelines

- Safety Data Sheet: EN, other languages

- Printing Profiles

Description

This stainless steel can be fully heat treated to high levels of strength and hardness. It is therefore ideal for Petrochemistry, Aerospace, and the Automotive. Parts printed with our metal-polymer composite filament Ultrafuse® 17-4 PH obtain their final properties through a catalytic debinding and sintering process known from traditional Metal Injection Molding.

Benefits at a Glance

- Easy and affordable metal 3D printing

- High mechanical strength and hardness

- Good corrosion resistance

- Fully hardened enables highest strength

- Wide range of post-processing options for green parts

Example Applications

- Tooling

- Jigs and fixtures

- Functional prototypes

Material Properties

- Heat-treatable stainless-steel parts

- Increased strength and hardness by precipitation hardening

- Martensitic

- Magnetic

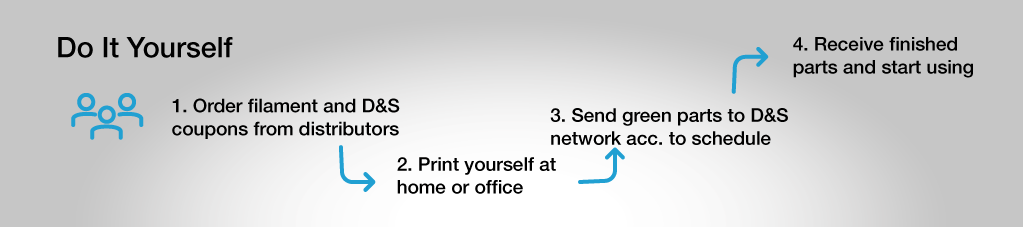

Print your Parts with Forward AM Materials!

Discover our comprehensive services and solutions here

Do you want to order Ultrafuse® 17-4 PH

Example Applications

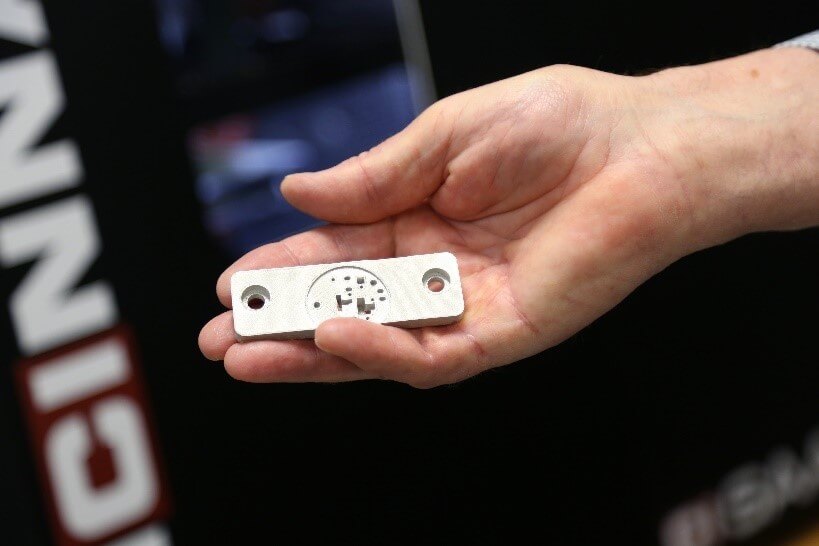

Spare Part Solar Panel Clamp

- Discontinued serial product

- Need for weather resistance (UV-radiation, heat, moisture)

- Long-life solution (upgrade from aluminium to stainless steel)

Spare Part Gate Lock

- Small-series production

- High mechanical strength required

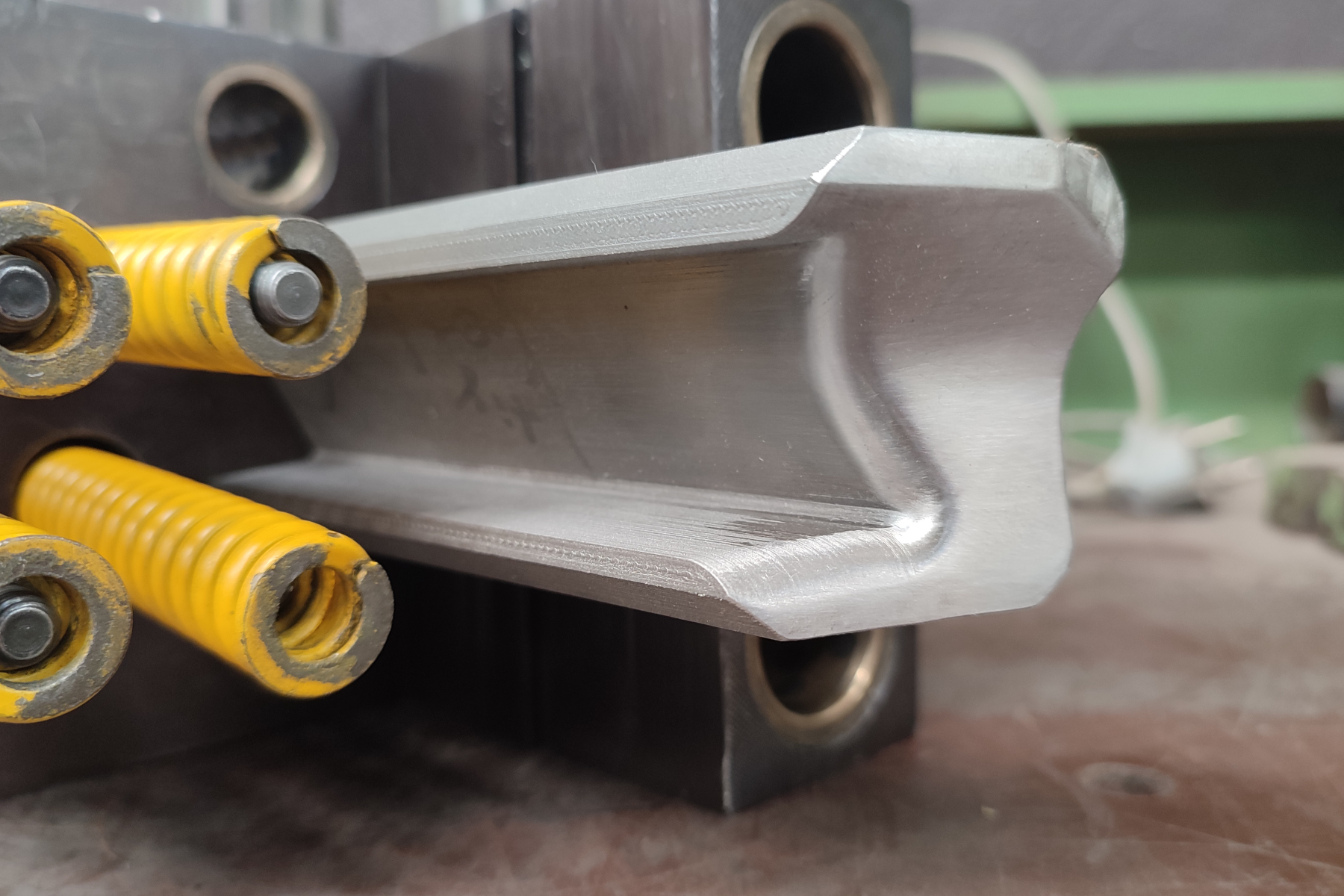

Customized Tool Insert

- Accessibility of individualized tools

- Increased productivity

- High stiffness for high tool loads

Use Cases and Whitepaper of Ultrafuse® 17-4 PH

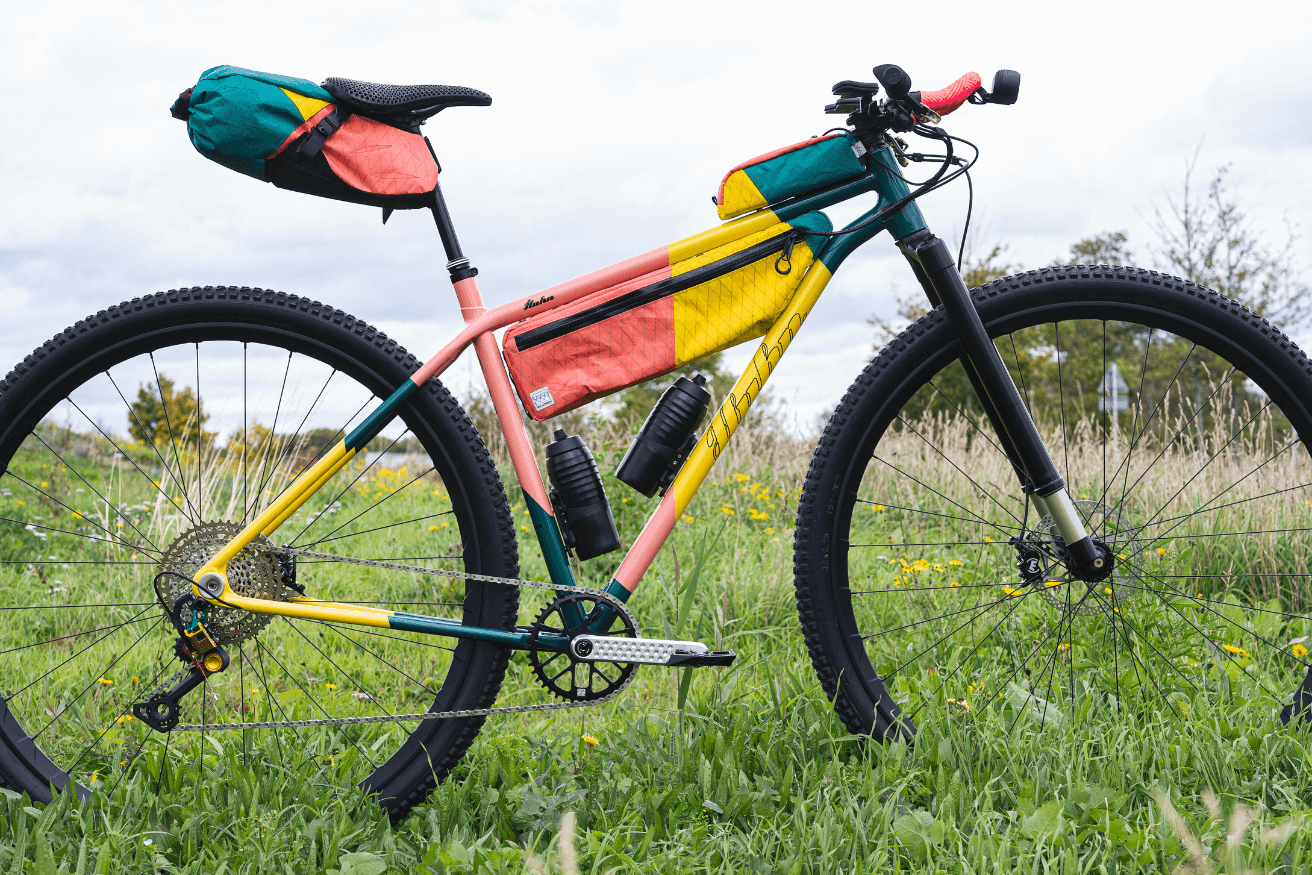

Innovative Materials and Technology Create Essential Metal Components for Custom Bicycle Frames

Innovative material and enhanced design provides superior performance and exceptional durability for industrial filtration screens

Automotive Industry Benefits from 3D Printed Prototypes Offering Extensive Design and Manufacturing Solutions

Metal Fused Filament Fabrication (MFFF) with Ultrafuse® 17-4 PH allows WKW.automotive to create the highly accurate and strong tools needed to…

Tooling Fixtures

Electronic communication systems, avionics, space intelligence, cyber security and weather monitoring solutions – American company L3HARRIS…

Our solution and added value for the customer

With Ultrafuse 17-4PH we offer an efficient way to produce metal parts with high mechanical strength. Ultrafuse 17-4PH is compatible with most FFF 3D printers, giving our customers a high degree of flexibility and freedom. Spare parts, tools or customized geometries are now easily and cost-effectively accessible.

Customer Reference

Next Steps

Printing Profiles

Select your printer below to access your printer profile. Click here to learn more about how to work with printer profiles.

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Metal Filaments

Ultrafuse® 316L

Stainless Steel Composite Metal Filament for 3D Printers

Benefits at a Glance

- Easy and affordable metal 3D printing

- Fast material exchange and easy handling

- For all open-source FFF printers

- Produces parts of stainless-steel 316L metal

- Uniform particle distribution enhances mechanical properties

Ultrafuse® Support Layer

Ultrafuse® Support Layer creates a barrier during sintering and facilitates the separation of support from the metal part

Benefits at a Glance

- Printable on any metal FFF printer

- Allows for a wider range of designs and complex geometries to be printed

- Excellent surface quality of supported areas of the part

- Minimize the distortion of the printed part during debinding and sintering