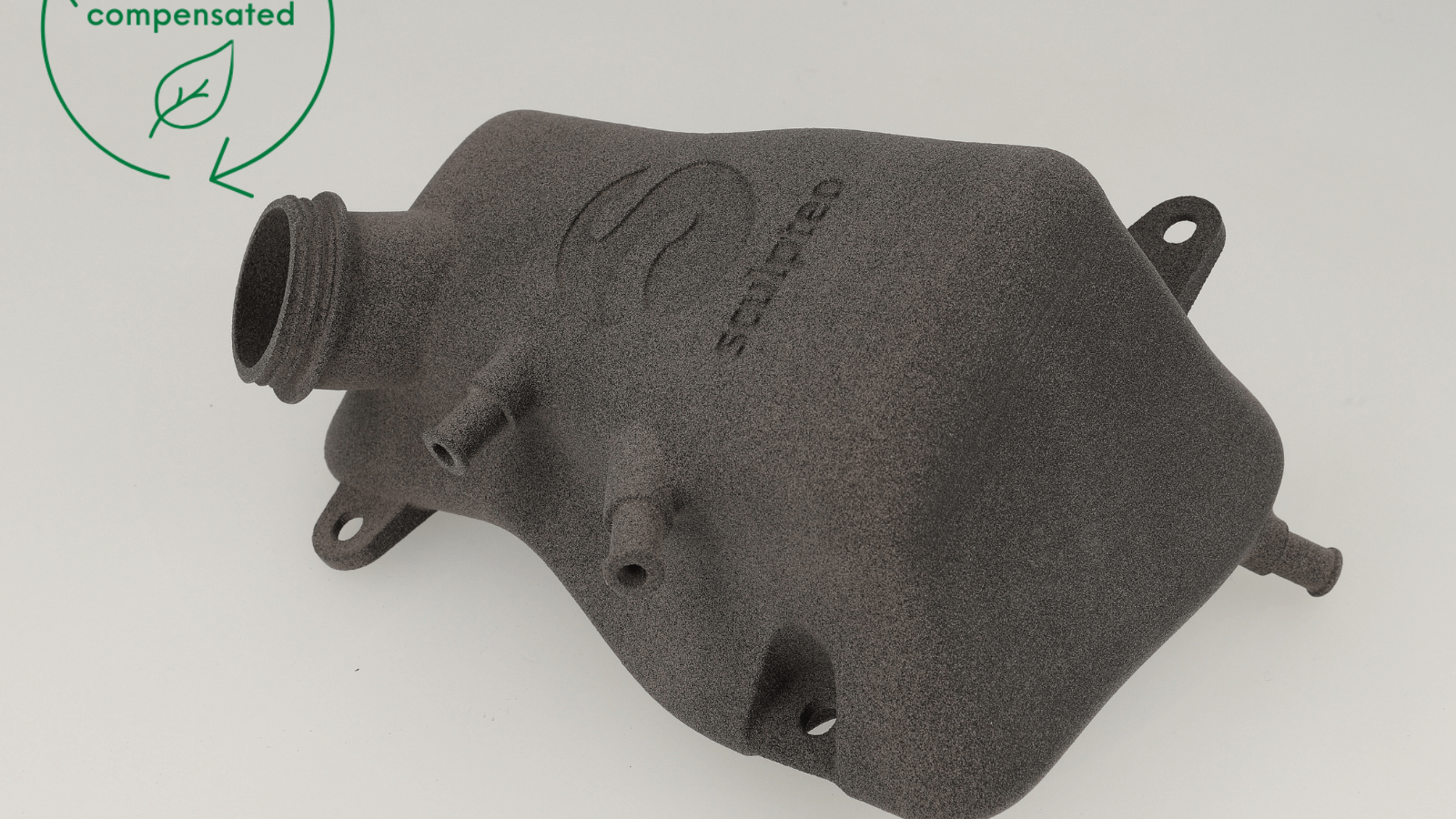

HP 3D High Reusability PP enabled by BASF

Fully functional polypropylene for use on HP JF5200 series printers

HP 3D High Reusability PP enabled by BASF makes commodity plastics finally available for HPs Multi Jet Fusion technology.

Description

With one of the highest throughputs and lowest cost per part in the industry, it sets new standards towards industrially proven serial production of fully functional parts. Its versatility makes the PP suitable for a wide range of applications from automotive to medical.

Sustainability Check

Lifecycle assessment available

Carbon compensation offered

Generally recyclable

Benefits at a Glance

- Genuine PP material for HP MJF technology

- Excellent chemical resistance

- Weldable with injection molded PP

- Low moisture absorption

- Appealing cost per part

- Up to 100 % reuse of surplus powder

- Color (printed part): anthracite

Example Applications

- Car interior parts

- Fluid and HVAC systems

- Tubes, pipes, reservoirs

- Medical devices

- Orthotics

- Functional prototypes

- Multi-purpose industrial goods

Material Properties

- Tensile strength: 30 MPa

- Young’s modulus: 1600 MPa

- Elongation at break: 20 %

- Charpy impact notched: 3.5 kJ/m²

- HDT B: 100 °C

Print your Parts with Forward AM Materials!

Discover our comprehensive services and solutions here

Use Cases and Whitepaper of HP 3D High Reusability PP enabled by BASF

Additive Manufacturing Delivers Complete Solutions for Optimizing Water Systems

Innovative material and enhanced design provides superior performance and exceptional durability for industrial filtration screens

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

Ultrasint® PP Product Range materials

Ultrasint® PP 1400 Black

Advanced Polypropylene Powder for a Wide Range of Innovative Applications

Benefits at a Glance

- Easy to process PP

- Isotropic behavior

- Excellent chemical resistance