Additive Manufacturing Delivers Durable Mold Parts for Quick Tool Production

DREIGEIST is driving Rapid Tool applications and Injection Molding into the future while maintaining both high-quality and reducing overhead costs

When updating products or changing technologies, companies often require prototypes or small batch sizes. The process to secure these essential parts can often be hindered by the high costs and long lead times of traditional injection molding. By utilizing Additive Manufacturing (AM), DREIGEIST provides 3D printed molds or mold inserts that are both cost-effective and have significantly reduced lead times.

Project Breakdown

Industry

Injection Molding/Tooling

Material / Product

Ultracur3D® RG 3280

Why Forward AM?

Ability to quickly produce durable and accurate molds in small batch sizes with high-quality materials and able to withstand the extreme IM process conditions

The result

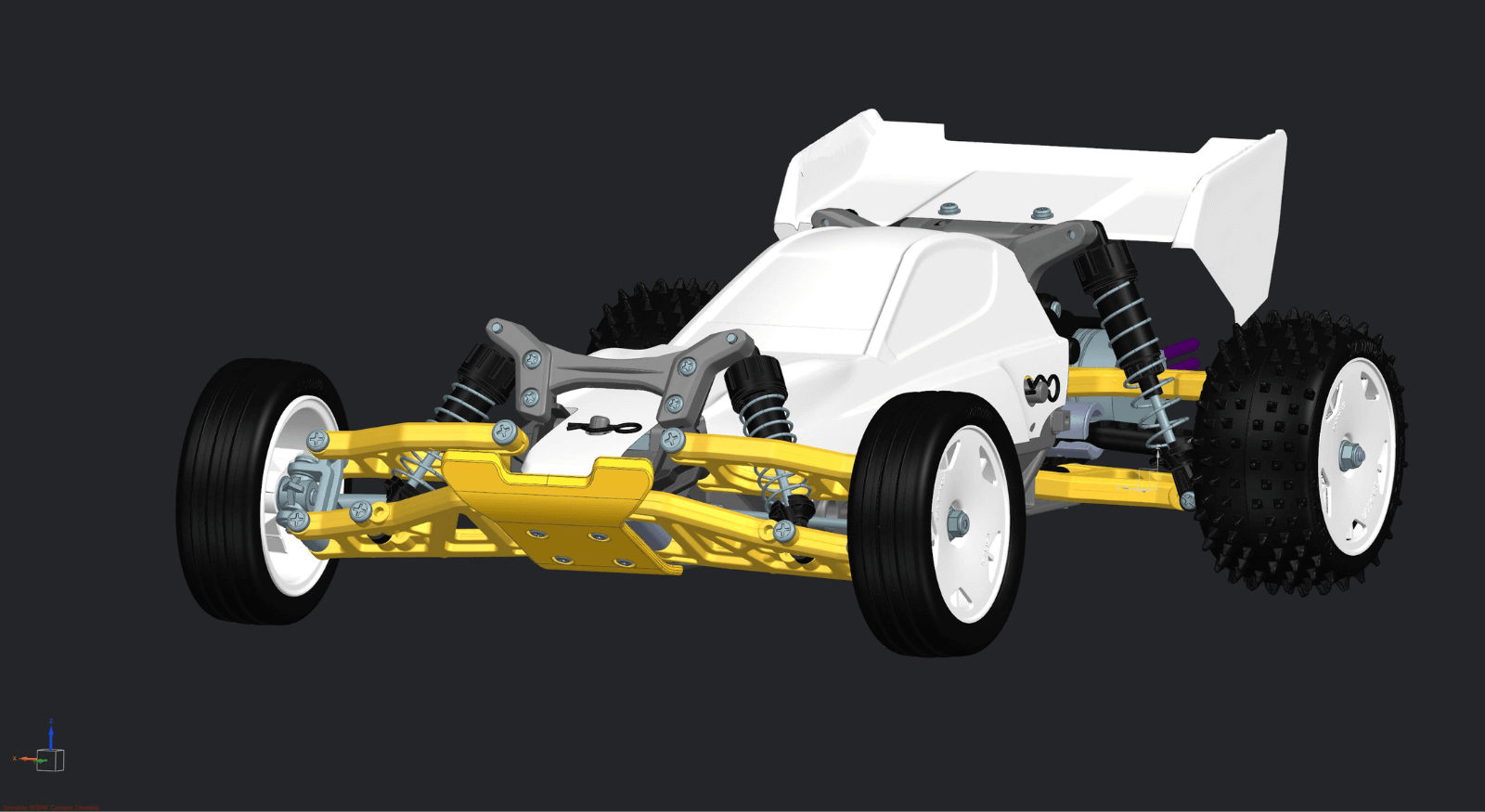

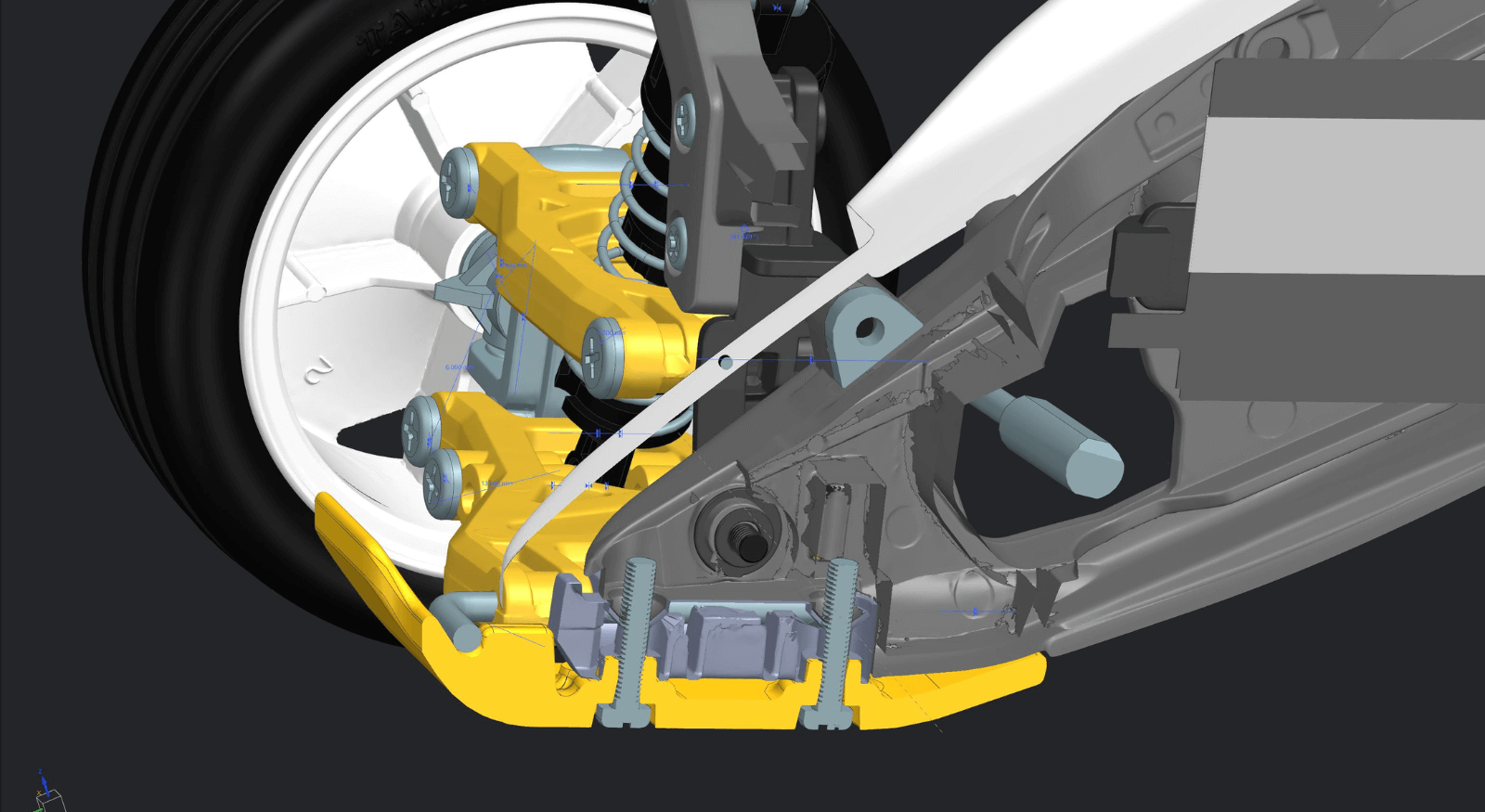

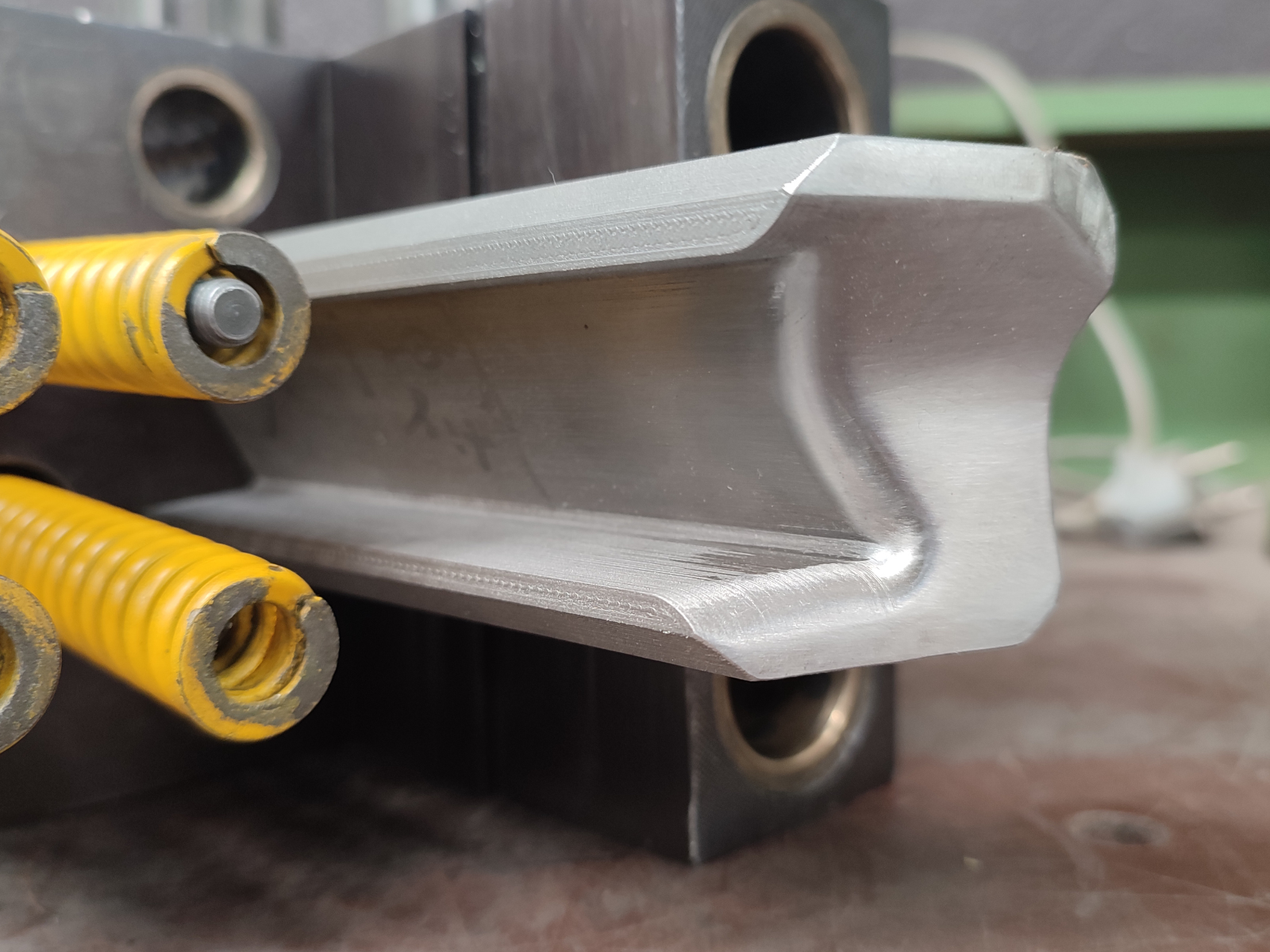

An injection molded bumper for high-performance RC cars

As Additive Manufacturing continues to change the way products are designed, engineered and manufactured, the ability to create innovative solutions is leading many companies in a variety of industries to adopt 3D printing. In 2015, DREIGEIST was founded by Christopher and Mareike König in Nürnberg, Germany with a focus on using the transformative power of 3D printing and making it a key success factor for companies. The name DREIGEIST, meaning “Three Spirits,” represents the tenets which guide the company: to Discover, Develop, and Deploy. By collaborating with Forward AM and capitalizing on our extensive material selection and project support, DREIGEIST is pushing the boundaries of 3D printing through the creation of injection molds using Ultracur3D® RG3280 and Digital Light Processing (DLP) technology.

Challenge: To create accurate molds or mold inserts in a short amount of time and for limited costs

When updating products or changing technologies, companies often require prototypes or small batch sizes, but can be hindered by the high costs and long lead times of traditional injection molding. The goal was to develop a process to produce high-quality and accurate parts via Injection Molding (IM) from part design to production in less than 24 hours. To meet this challenge, 3D printing was chosen for its demonstrated ability to quickly facilitate tool design changes and part production while meeting quality standards and timeline demands.

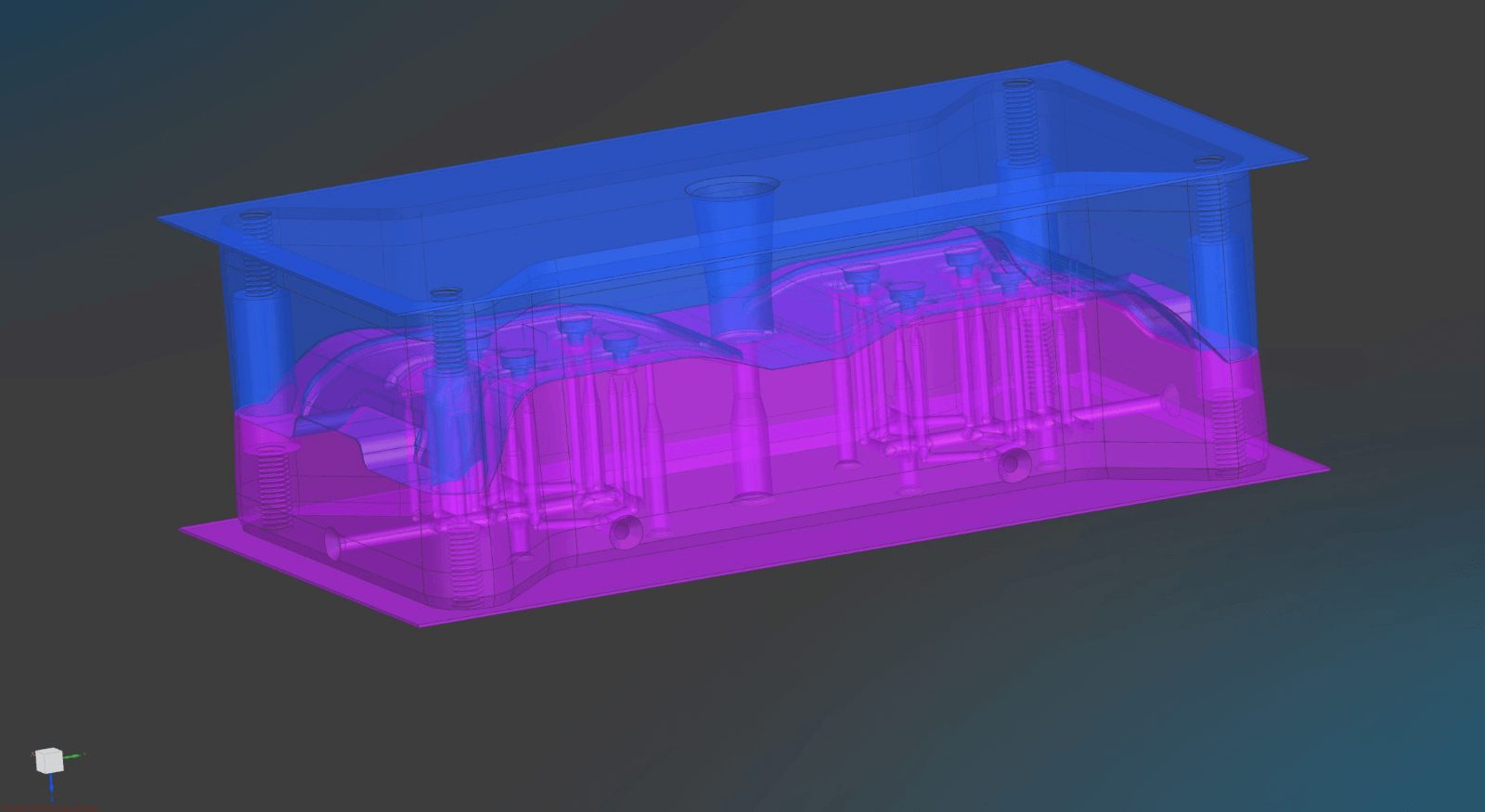

Traditional manufacturing uses conventional techniques for tool making such as milling. However, the milling process requires multiple processing steps resulting in extended production time when compared to AM. 3D printing technologies would ensure the design could integrate the necessary enclosed ventilation drills, a step which would not be possible through traditional milling methods.

The final challenge was to determine which 3D printing material would be able to withstand the extreme IM process conditions such as clamp force, injection pressure, high temperatures, and fiber-reinforced thermoplast processing.

Solution:

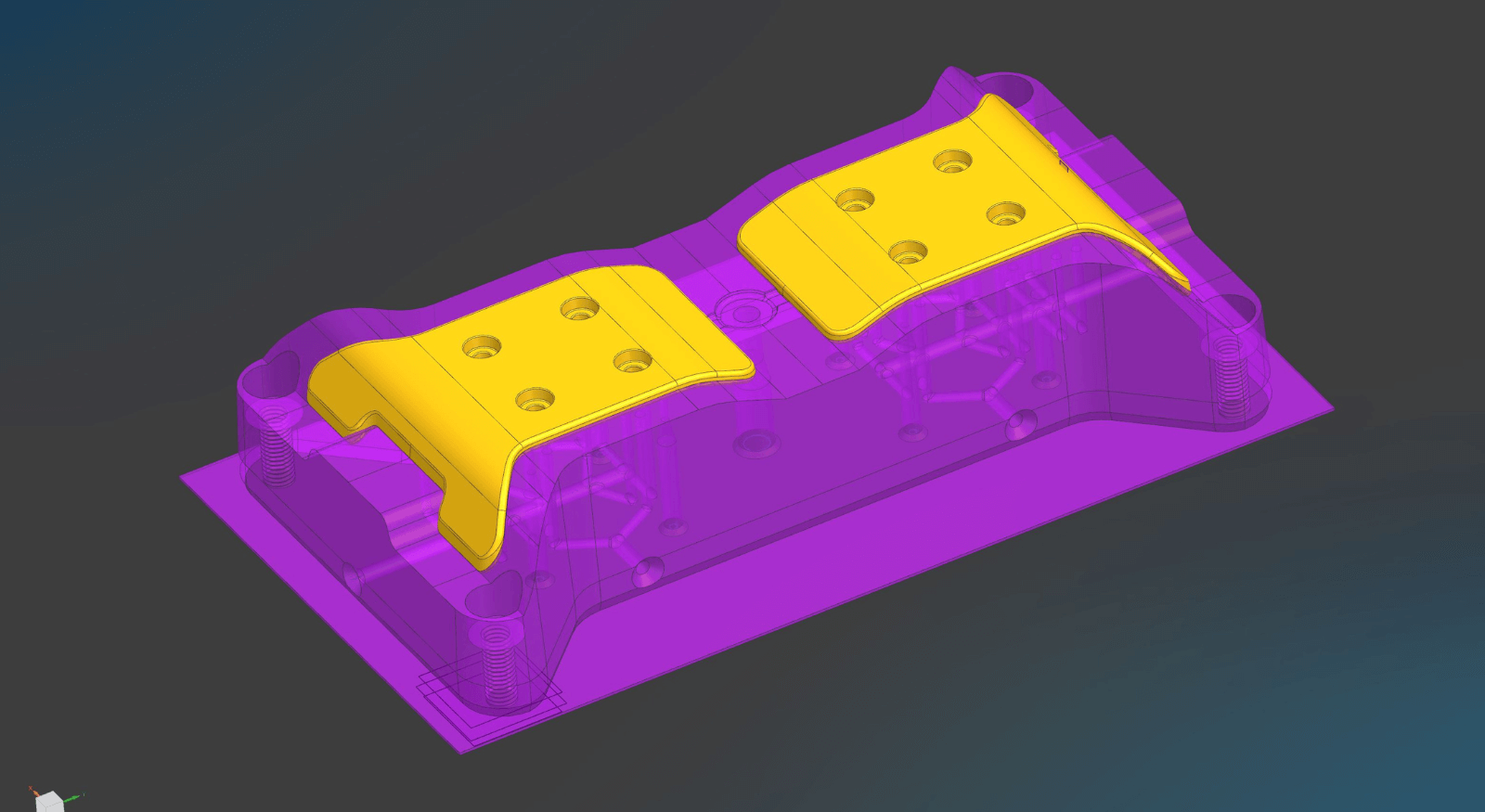

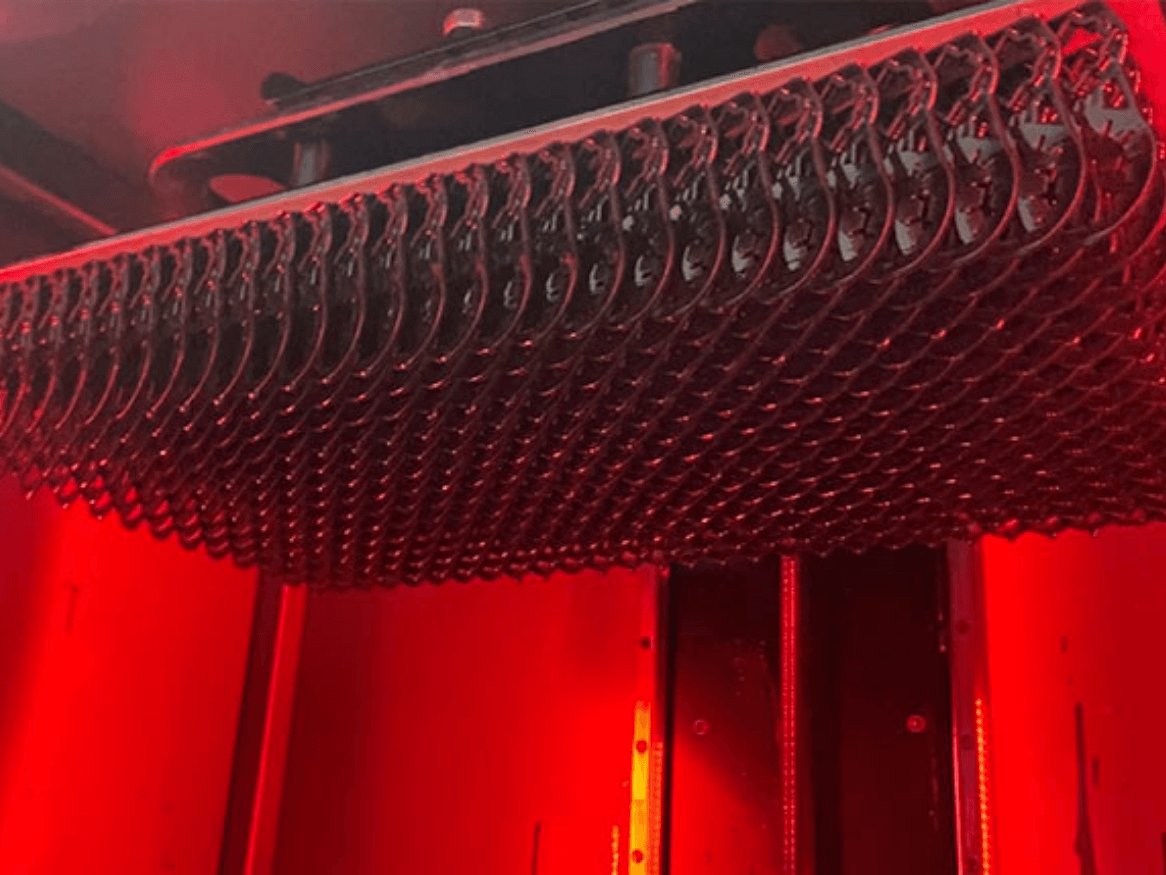

With the ability to meet all the above challenges, Ultracur3D® RG 3280 is the perfect material for injection molding with qualities that meet or exceed the characteristic process requirements as well as ensure an increase in production speed for mold making. This advanced resin material is filled with ceramic particles, delivering superior stiffness and high HDT which are both necessary for the IM process conditions. Ultracur3D® RG 3280 also allows for the precise printing of lattice structures providing the ability to create a part with a fully optimized design.

Ultracur3D® RG 3280 is also engineered for use with DLP technologies. While SLA can provide a higher resolution in the curvatures of the X-Y plane, the projector-based DLP process offers shorter build times. This results in a decrease in production time while still ensuring the part will maintain a high heat deflection temperature and superior stiffness.

The required the post-processing was usual for resin printing which included washing, UV curing and a thermal post-cure. And to fit the mold base perfectly, the back plane needed to be evenly milled.

Result:

This application of Rapid Tooling demonstrates what is achievable with AM and how 3D printing drives conventional part production techniques such as Injection Molding forward.

Ultracur3D® RG 3280 in combination with DLP technology offers easy, fast, and detailed printing of a material possessing the required characteristics of high stiffness, increased strength and heat deflection. There was also a significant cost savings through Rapid Tooling as production through conventional methods such as milling (creating two halves) of around the same size, can vary in cost from 2500 to 6000 Euros and take between four to six weeks to deliver. By implementing in-house 3D printing, the net cost of a tool through AM is less than 500 Euros and can be realized within 9 hours of total processing time.

By utilizing innovative materials like Ultracur3D® RG 3280 from Forward AM, DREIGEIST can offer customers shorter process chains, lower production costs, freedom of design, as well as the ability to shorten the part production cycle from design to the manufacturing of IM components to less than 24 hours.

“Additive Manufacturing of injection molding tools for small series applications has it all; Freedom in design, short process chains, and parts that exceed all expectations!”

Christopher König, Co-Founder and CTO of DREIGEIST

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!