Cycling Enthusiasts Find Increased Comfort and Improved Performance Through Customized Bike Saddles

The precision design and innovative materials available with 3D printing provides cost-efficient production and scalable mass customization to meet individual customer needs

Posedla was exploring ways to offer cyclists something more than off-the-shelf saddle options. By utilizing Ultrasint® TPU01, they were able to create an innovative lattice-based design and manufacture a customized bike saddle which optimized features to benefit both the comfort and health of the athlete as well as increase performance.

Project Breakdown

Industry

Consumer Goods

Material / Product

Ultrasint® TPU01

Technology

MJF 5200

Why Forward AM?

Complex lattice structures and scalable mass customization

The result

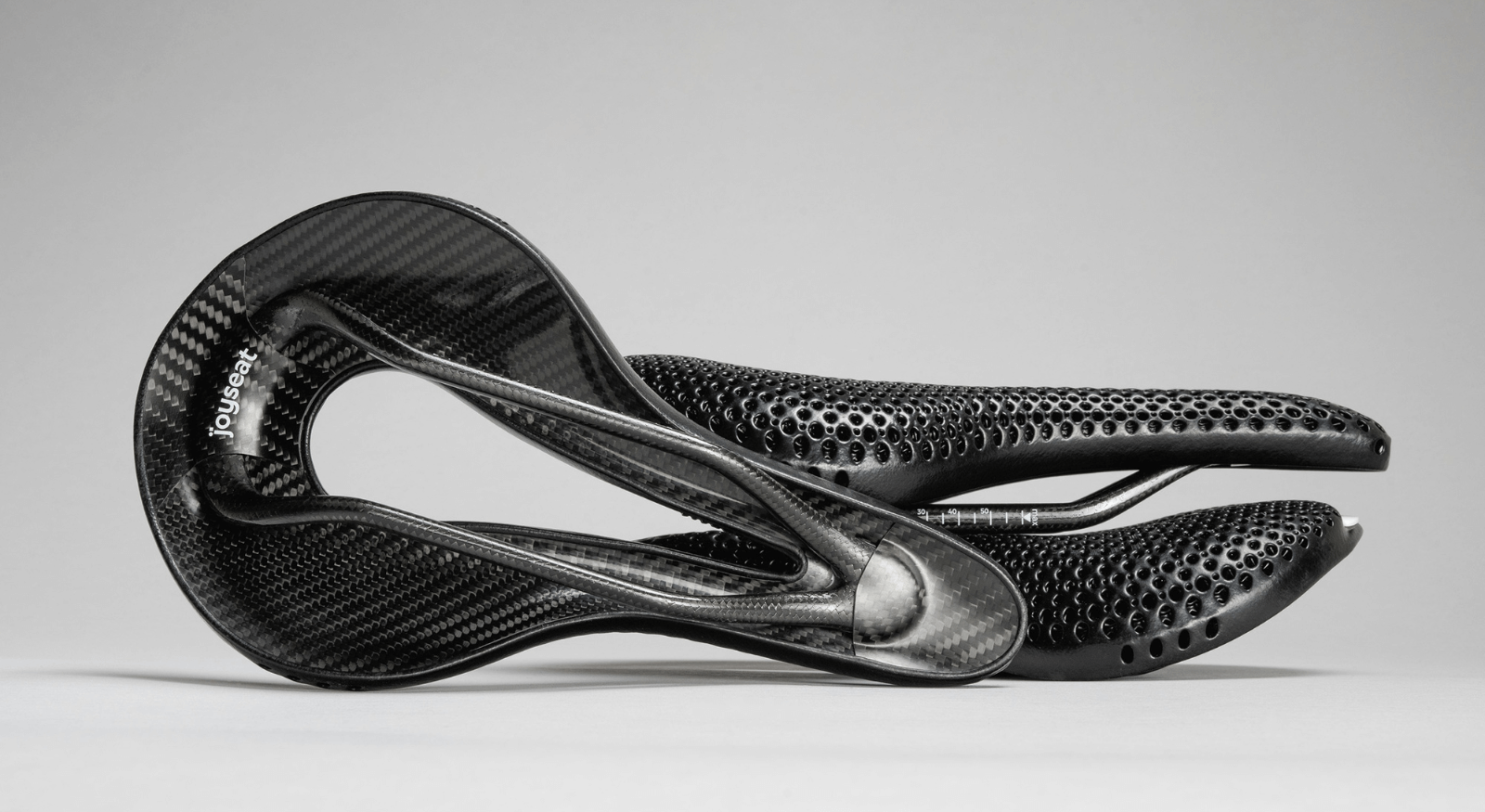

Customized Bike Saddle (The Posedla Joyseat)

With foam having hit a plateau regarding design and functionality, bike saddle manufacturer Posedla turned to Additive Manufacturing with Ultrasint® TPU01 from BASF Forward AM. This innovative material was used to create lightweight, custom saddles which provide cyclists with both improved performance and increased comfort. The company was founded in the Czech Republic by Martin Ripa and Jiri Duzar, both passionate cyclists who turned a hobby into a business with the unique goal to create customized bike saddles for every level of cyclist. After hundreds of design iterations and countless hours of discussions while riding, the Joyseat was launched in May of 2022 and is the world’s first custom-made 3D-printed saddle.

Beginning with an algorithm based on the individuals needs and preferences along with the “Smiling Butt Kit,” cyclists can purchase uniquely customized saddles created with Ultrasint® TPU01 utilizing complex and intricate lattice structures, which are only possible through 3D printing. This innovative material and tailor-made design ensure higher levels of comfort throughout multi-pressure zones, as well as an aesthetically pleasing look and feel.

Challenge:

For decades, bike saddle manufacturers have relied on traditional forms of manufacturing to produce standardized bike saddles. This has led to little variation in terms of structural and design possibilities. Bike stores offer a variety of different shapes, sizes and technologies, but to-date customized saddles have not been readily available for individual non-professional riders.

Cyclists’ demands differ depending on their activity and standard saddles simply cannot cater to unique personal requirements, such as commuting short distances in urban areas or sports biking, as each activity can require a saddle that provides different levels of stiffness and flexibility. In combination with the type of riding the athlete is participating in, saddles must also meet the specific needs and preferences of the individual regarding height, weight and gender. As men and women have differing pelvic anatomies, it is imperative that the shape and the stiffness of the padding in the individual zones of the saddle are produced specifically for male and female cyclists, ensuring a healthy and comfortable riding position for both.

Companies have found it difficult to develop unique equipment designed to suit each user, as the ability to produce customized parts through traditional manufacturing is both cost-prohibitive and time consuming. To help meet this challenge, BASF Forward AM offers 3D printing solutions to bicycle manufacturers giving them a significant advantage in their abilities to create customized parts adapted to an individual.

“The promise of 3D printing saddles from the start was the actual individual customization for each rider, but that never really materialized until Posedla and their Joyseat. I’m really excited about their customization process.”

Cory Benson, EU Tech Editor, Bike Rumour

Solution:

The design and production process begins with an algorithm based on a questionnaire about the individuals’ type of bike, the average time and miles spent riding, the body position on the bike, physical flexibility off the bike as well as age, gender and weight. Using this information, along with the “Smiling Butt Kit,” cyclists can order uniquely customized made with Ultrasint® TPU01 and utilizing Additive Manufacturing techniques which deliver a fully dimensional production platform along with the ability to produce complex and intricate lattice structures, which are also only possible through 3D printing.

Parts printed with Ultrasint® TPU01 deliver on strength, flexibility and durability when it comes to performance. Combined with excellent surface quality and level of detail, this material opens unlimited design possibilities as it is extremely easy to print, scalable and combines very high process stability with one of the highest throughputs of flexible materials in the 3D printing market. TPU01 is also designed for comfort, high replicability, and has a proven success rate with vapor smoothing methods. These unique characteristics make it a perfect fit for bike saddle serial production with HP Multi Jet Fusion printers.

Additionally, Ultrasint® TPU01 shows excellent weather and UV resistance, which also makes it ideally suited for this application. Its high recyclability rate means a very low-waste manufacturing process and since it’s a thermoplastic, the material can be recycled easily meeting one of the key sustainability requirements for the modern consumer industry.

Upon receiving the ten ride parameters and a picture of the “Smiling Butt Kit” imprint, a unique algorithm designs every single aspect of the saddle to create the perfect match for the cyclists’ distinctive anatomy which can then be 3D printed. Through this specially developed process, Posedla can manufacture a custom saddle based on the athlete’s sit bone width and weigh distribution, with the one-of-a-kind impression generating a pressure map, indicating the precise mass and pressure distribution applied to the saddle by the individual.

“I have tried 10 to 15 brands in my career so far. Every saddle is a bit different, but the Joyseat is the only one with which I managed to not have a chafed butt after 25 hours of riding a week.”

– Daniel Turek, Professional Cyclist from the Czech Republic

Result:

A perfectly individualized, lightweight and durable saddle that optimally distributes bone and muscle pressure, maximizing rider comfort by minimizing peak-pressure points. Through the utilization of complex and intricate lattice structures, only made possible through the 3D printing of Ultrasint® TPU01, the Posedla Joyseat provides customized features to benefit both the comfort and health of the athlete as well as increase performance.

The Posedla team noted that without Ultrasint® TPU01, “…the level of customization we offer in our product would be otherwise impossible to achieve.” They have also successfully reduced the production time from ten weeks to between three to four weeks, with their manufacturing plant at full capacity. In addition, there has been a significant reduction in the weight of the product, which now stands at less than 140 grams. And while not specifically designed to be ultralight, this added benefit gives the Posedla Joyseat a competitive edge compared to non-custom and more expensive standard bike saddles on the market.

Finally, another fundamental aspect was the post-processing of the final product. AMT, known for its advanced post-processing solutions, enables the certification of parts for use in the most demanding industries. In the case of the 3D printed saddles for Posedla, AMT PostPro’s Vapor Smoothing technology was the best choice. The vapor smoothing method, as the name suggests, seals the porous surface of the saddle, reinforcing its mechanical and structural properties, while also giving it a final finish similar to injection molding. As a result, Forward AM’s Ultrasint® TPU01 material was able to pass skin contact and irritation tests after being post-processed with Vapor Smoothing. In addition, end-use parts were tested for mechanical damage and fatigue and passed with flying colors, meeting ISO standards for bicycle saddles.

“We managed to break the mold of assembly-line production of saddles by taking full advantage of industrial 3D printing. We are driven by positive feedback from our customers who appreciate comfort and welcome the possibility of finally having a fully customized saddle.”

Martin Ripa, co-founder of Posedla

Listen to a Podcast from the Kolektif Berlin Bike Fair about 3D printing and mass customization in cycling industry at: https://posedla.com/blogs/podcast/live-from-kolektif-berlin-bike-fair

Learn how to use the “Smiling Butt Kitt” here

Posedla was among the Czech TOP innovators for 2022. They were also featured in the Best Bike & Gear Awards for 2022 as part of the prestigious American magazine Bike Rumor.

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!