Protective Lattice Layer for Cobots

How Forward AM and OECHSLER Enable Robots and Humans to Collaborate Safely at Profitable Speed

In today’s modern factories around the globe, many production steps are automated and carried out by robots.

Project Breakdown

Industry

Robotics

Product

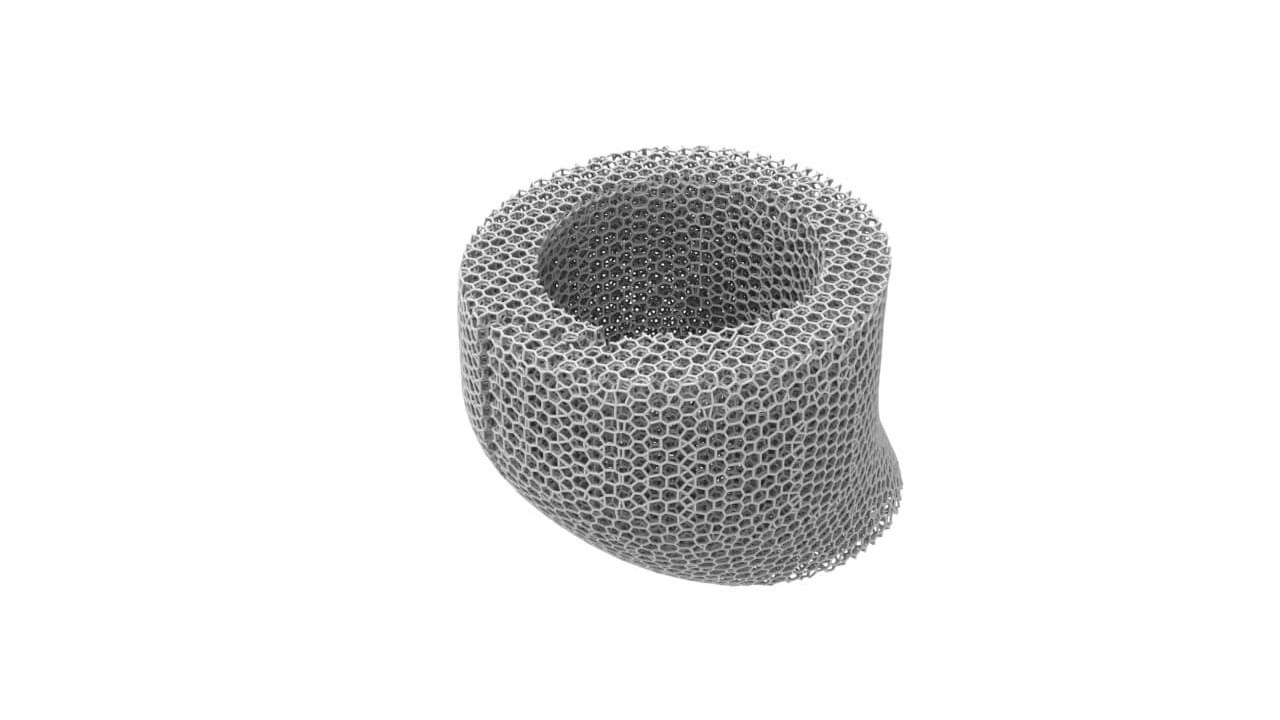

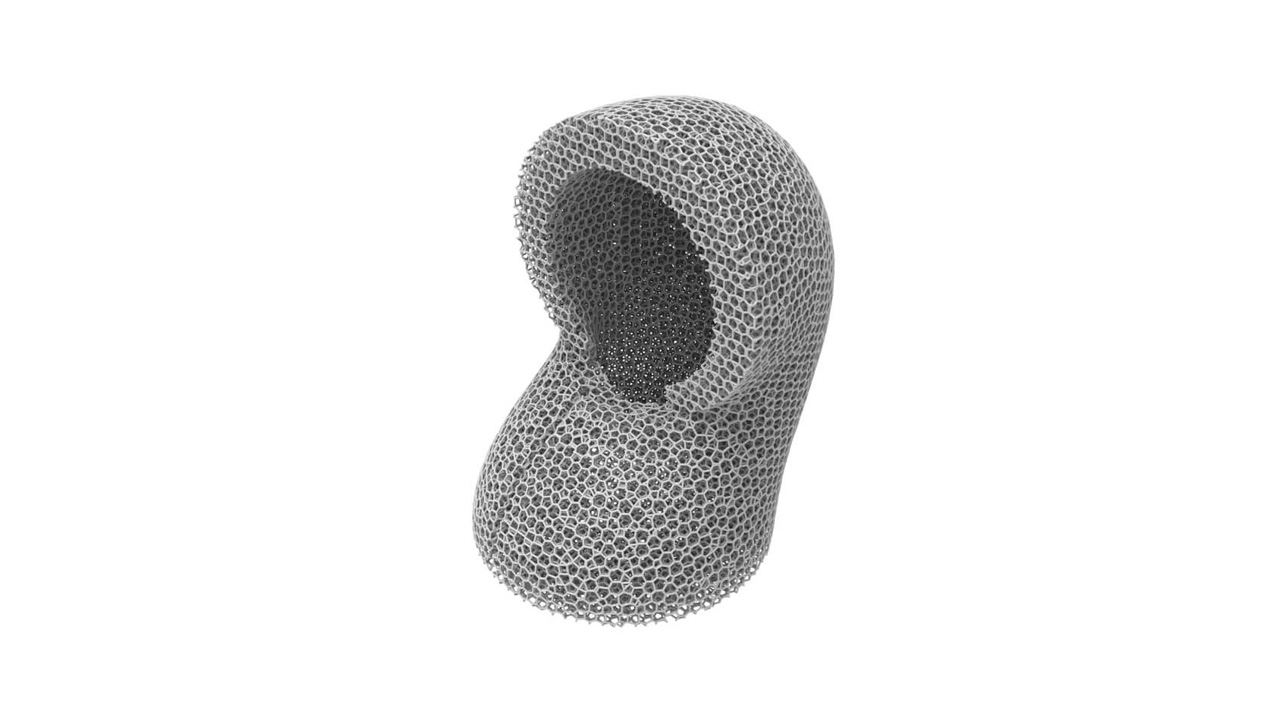

Protective lattice layer for cobots & end of arm tooling (EOAT)

Why Forward AM?

Perfect-fit material for lattice application

Material Used

Ultrasint® TPU01

The result

Lattice skin that adds protective layer to robots in close cooperation with human workers, enabling increased safety and higher productivity

Humans sharing a workspace and collaborating with robots has become a reality that companies and their smart factories just can’t do without, as it allows flexible manufacturing in variable batch sizes with maximum efficiency. In short, successful human-machine interaction is key for future-proof manufacturing.

With Additive Manufacturing (AM), it is now possible to create new functionalities for robots and to unlock novel possibilities. The AM technology is perfectly suited for the production of small, customized batches for robotic parts like grippers – and it is ideally capable to integrate internal ducts, as air pressure and vacuums play an important role in this industry.

The challenge – safe human-robot collaboration at profitable speed

Collaborative robots (short: cobots) become increasingly present in manufacturing. Designed to work alongside humans in shared areas, they work together ‘hand in hand’ – which makes it crucial to ensure safety by avoiding collisions of cobot and human co-worker.

This is prevalently achieved by inherent optical sensors which trigger an immediate stop of the cobot in case of unexpected contact: whenever a human co-worker enters the defined warning zone, the system lowers its speed to a minimum and if the person keeps approaching, the system stops – only after the individuum departs, the system accelerates back to full speed. It’s obvious: this results in highly limited processing speeds of the cobot and thus higher cost and lower productivity for the manufacturing company. These interruptions in the workflow may lead to unstable cycle times as well, and foremost – it is absolutely contrary to the intention of cobots being deployed flexibly and easy to integrate as a plug-and-play system: To achieve an appropriate reaction to an approaching human co-worker, cobots have to be programmed accordingly; always depending on the cobot’s task, its exact form of cooperation with the human worker, and its physical position in the factory. Whenever the cobot is deployed at another workstation on the assembly line, or performs different tasks and movements, its programming has to be adapted. This limited flexibility only allows pre-defined reactions of the cobot.

The solution – a protective lattice skin for cobots made of Forward AM’s Ultrasint® TPU01

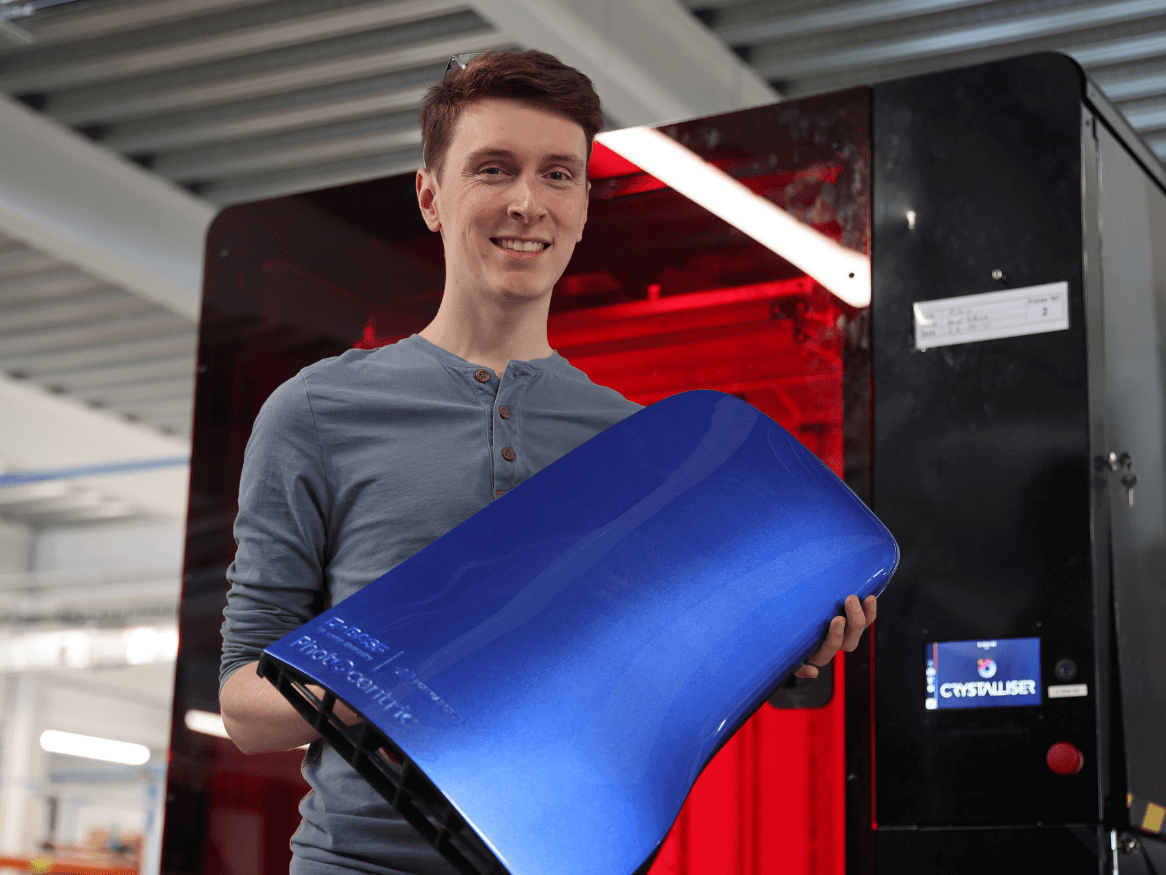

A new approach by Forward AM and OECHSLER, a leading German polymer processing company, enables humans and cobots to share a workspace without any safety risks and manufacturing companies to keep productivity constantly high.

How? By adding a new layer to the current solution – literally. A thin, high cushioning second ‘skin layer’ is wrapped around the cobot’s joints. Using Forward AM’s Ultrasint® TPU01 to 3D print the RoboSkin enables a flexible and individualized lattice structure. Ultrasint® TPU01 is a thermoplastic polyurethane powder specifically designed for HP 5200 series Multi Jet Fusion printers. This flexible material is ideal for producing parts requiring high shock absorption at excellent flexibility depending on the functional requirements of the application, making it the perfect match for the cobot’s protective skin and its cushioning function.

The benefits of the lattice RoboSkin are manifold. Putting safety first, it reduces the risk of injuries to human workers interacting with the cobot. At the same time, production speed can be increased strikingly: Since the collision forces and pressures are highly damped by the RoboSkin, the cobot’s speed can accordingly be higher up to 150 percent– thus enabling increased productivity for the manufacturer.

The overall handling of the skin is easy: Because the RoboSkin works as a mechanical collision buffer, it requires no additional sensors, just the TPU layer that takes up only minimal installation space and is mounted with an easy system. Moreover, the lattice design of the skin is easily, rapidly and cost-effectively adaptable to every cobot type, thanks to the advantages of 3D printing. In production halls, cobots are often deployed at different workstations. The RoboSkin eliminates the need for dismantling, re-assembly and re-calibration, thus saving time and cost.

An additional benefit of the lattice structure is that it acts as permeable skin, preventing heat accumulation thanks to its open structure. What’s more, it serves as an isolating layer as it covers the cobot’s supply hoses and wires. At the same time, it works without restricting the cobot’s movements, overheating, additional sensors, or work area surveillance.

“The RoboSkin solves a complex problem with a seemingly simple solution, enabling the end user to optimize the productivity of the human-robot-collaboration application. With AM, we can offer a configurable soft skin according to the safety needs at reasonable pricing – and which is reliable, easy to handle, lightweight, space-saving and permeable to ensure profitable performance.”

Meike Wischgoll, Program Manager, OECHSLER

Together, OECHSLER and Forward AM are enabling a solution that delivers a significant increase in safety and productivity. Harnessing the advantages of AM, human workers and cobots can work together at minimum risk of injury while maximizing productivity.

Have we sparked your interest? Get in touch and dress up your cobot with our innovative RoboSkin!

For more information about OECHSLER and its solutions in Additive Manufacturing, head over here.

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!