PlastiPUSH Hand Spikes

Smart Car Bodywork Repair – with Plastfix and Forward AM

Every car driver out there knows it only too well – just a split second of distraction and the car bodywork shows an annoying dent. Plastic fender dents are blemishes on otherwise perfect-looking vehicles, so it’s no surprise that removing these is bread-and-butter business for auto repair companies.

Project Breakdown

Industry

Industrial / Automotive

Product

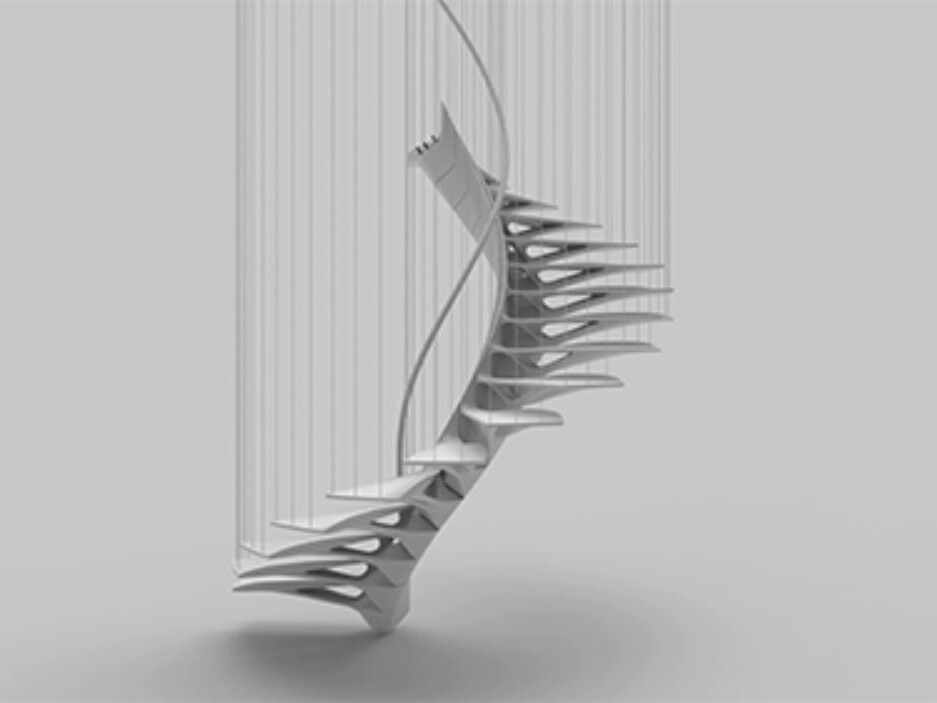

PlastiPUSH Hand Spikes

Why Forward AM?

Perfect-fit AM material, expert scale-up support

Material Used

Ultrafuse® PLA, Ultrafuse® PLA PRO 1

The result

Vehicle plastic bodywork repair with 3D printed hand spikes, providing increased functionality at lower cost than traditional filler

Challenge: Restoring not replacing exterior plastic car bodywork

For collision repair centers, the traditional approach to repairing a fender dent means using fillers, or if that falls short, even replacing the whole fender. But working with fillers always entails adding an additional layer of foreign material plus solvent, which brings several risks: The overall component weight is increased, and adhesion issues with the coating, cracks or deformations often occur, leading to a decrease in component performance. In short, using fillers goes hand-in-hand with a great deal of warranty-sensitive work that consumes both time and money.

Solution: First 3D printed end-user tool for the collision repair industry

Searching for a way to make this frequent repair operation more efficient, Australian startup Plastfix has developed an innovative solution: The Plastfix Repair Process, which leverages Additive Manufacturing and advanced 3D printing filaments by Forward AM.

How does it work?

By applying a combination of heat and 3D printed hand spikes, automotive plastic components can now be returned quickly to their pre-collision shape.

PlastiPUSH hand spikes are 3D printed with Forward AM’s advanced Ultrafuse® PLA and Ultrafuse® PLA PRO1. These highly impact-resistant, thermally stable Fused Filament Fabrication (FFF) materials not only enabled Plastfix to print and test different tool designs in a cost-effective way but also to produce the definitive hand spikes quickly in small batch runs.

Plastfix knew rapid, agile action was the key to gaining market traction, printing production runs as small as a single set of PlastiPUSH hand spikes while scaling-up their new business – perfect conditions for harnessing the benefits of Additive Manufacturing. Plastfix identified the perfect-fit materials for their innovative idea as Ultrafuse® PLA and Ultrafuse® PLA PRO1 by Forward AM. Having tested numerous different filaments, Ultrafuse® PLA offered the best quality and highest printing consistency, both vital factors for this fast-growing company with global scale-up on the horizon. Printing with Ultrafuse® PLA is exceptionally simple, making scale-up easy as no dedicated 3D printing experts are required.

Moreover, using plastic filaments for a tool to repair plastic vehicle fenders is highly advantageous: It replaces sharp-tipped tools that can perforate warm plastic parts, as well as inappropriately blunt tools such as screwdriver heads. Coming in a wide variety of color shades, Ultrafuse® PLA also allows Plastfix to 3D print in colors and designs customized for each collision-repair shop.

“Thanks to Ultrafuse® PLA we were able to get our innovative solution to market very quickly. We see Additive Manufacturing as key pillar of our expanding business – and with Forward AM’s expertise and advanced materials, we have a strong partner by our side for this journey.”

Mario Dimovski, CEO Plastfix

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!