The #vanlife of the Future – Realized by BASF for HYMER

Concept Van HYMER VisionVenture

Global demand for premium Recreational Vehicles (RVs) has been rising continually for several years now and is currently at an all-time high.

Project Breakdown

Industry

Automotive

Product

Exterior Side Cover, Wheel Arch, Interior Lamp

Why Forward AM?

Perfect-fit Materials, Virtual Engineering Expertise, Post-Processing Solutions

Forward AM materials used

Ultracur3D® EPD1006, Ultrasint® TPU01, Ultrafuse® 316L, Ultrasint® PA6 FR, Ultrasint® TPU 88A, Ultracur3D® Coat F+

The result

Fast and cost-effective appearance prototypes

Destination: Freedom

More and more vacationers want to escape the uniformity, inflexibility and high cost of hotel destinations, and shun the inconvenience of camping in adult life. They prefer freedom of choice regarding their vacation destination and the ‘mobile cocoon’ lifestyle that a modern RV such as a campervan offers. Some are even selling up their bricks and mortar dwellings completely and moving permanently into a fully-featured, spacious and highly mobile home on wheels.

So how will RV life look in 2025?

This is the question that HYMER, the world’s leading manufacturer of premium campervans, and BASF asked themselves back in 2018. The joint answer is the HYMER VisionVenture: a fully functional and outstandingly well-equipped glimpse into the future of campervan life. Using more than 20 innovative BASF materials and the development expertise of the BASF Creation Center, HYMER has created a new class of campervan that completely changes the game thanks to its lightweight construction, energy efficiency and autonomy, and a whole new level of ergonomic interior design.

Conceived completely from the ground up, the campervan of the future features groundbreaking solutions based on advanced BASF materials for the vehicle’s bodywork, energy management, thermal insulation, lighting, heating and entertainment systems as well as bespoke NVH (Noise, Vibration and Harshness) measures. It features over 100 3D printed components from Forward AM, using four high-performance materials such as the exterior side covers, individualized wheel arch linings and an interior lamp.

Challenge: Fast and cost-effective appearance prototypes for concept vehicles

When developing concept vehicles like the VisionVenture, part production is oftentimes challenging: low volume production of only one piece per part, numerous design iterations to identify the final part and all this without having specific tools in place. AM is the perfect solution for these requirements, as it enables appearance prototypes providing the design of the final part without having to perform like the series part.

Exterior side covers

On modern RVs, they need to be able to take heavy punishment over hundreds of thousands of miles in harsh operating conditions and extreme temperatures. They need to demonstrate long-term structural resistance to vibration, pebble impact, thermal deformation and UV degradation, minimize NVH and maximize thermal insulation to optimize passenger comfort – and all this at minimal component weight to contribute to excellent vehicle fuel efficiency.

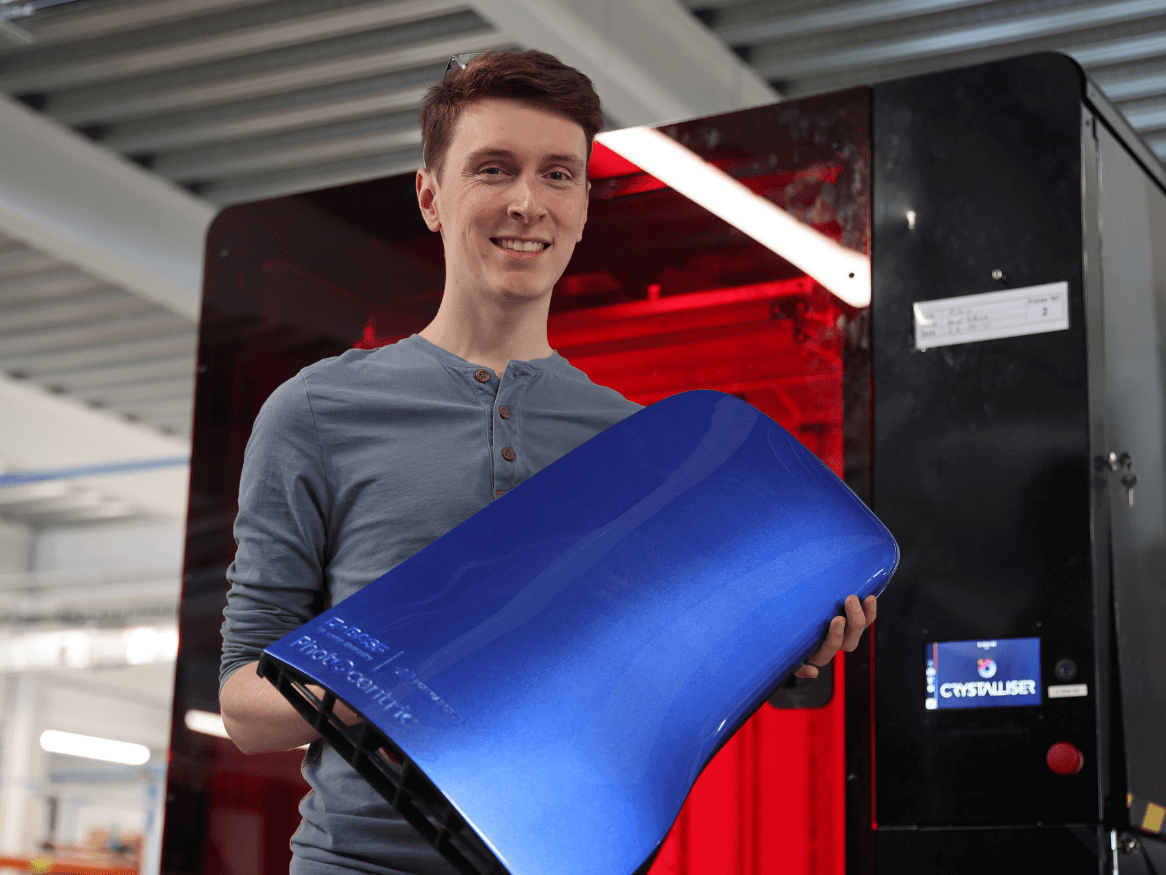

For this application, the material had to accelerate design iterations in the prototype phase to significantly reduce development costs, deliver a perfectly smooth surface that was easy to finish and coat and be 3D printable in matching dimensions as well.

The material of choice for the large panels is Forward AM’s Ultracur3D® EPD 1006, which proved to be the stand-out solution to accelerate design iterations in the prototyping phase, thus minimizing development cost and maximizing speed to the definitive component. The initial tests confirmed that the exterior side covers in Ultracur3D® EPD 1006 printed quickly and with extremely high structural consistency, with minimal post-processing effort required to produce perfect coating results in finishing.

Wheel Arch

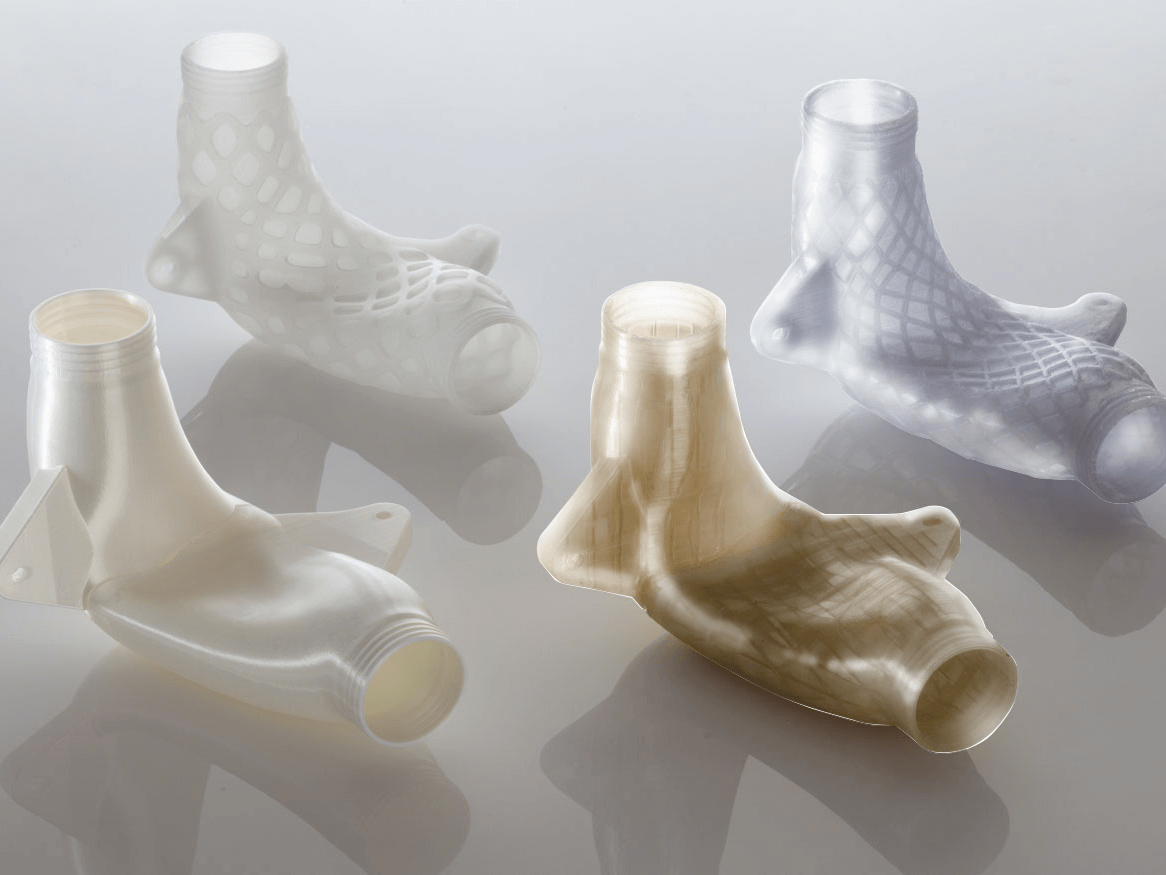

Looking at another component, Forward AM was challenged to design a mass-customizable wheel arch lining for the VisionVenture.

Campervans are often sold to rental agencies as well as to individual consumers. Both customer groups have a strong desire to customize their vans – private buyers wanting bespoke fittings and finishings on their vehicle to reflect their own unique tastes and personality, while rental fleet operators require their highly mobile investments to display their unique company logos. Granting this wish has so far been prohibitively expensive, as mass customization has not been economically viable for OEM RV brands using traditional manufacturing materials and technologies. Worse still, a corporate design, logo or name applied as a coating or foiling can discolor or even structurally degrade the underlying material, often necessitating a full panel replacement or at least a full professional respray. This makes removing or renewing customized exterior elements on RVs very time and cost-intensive.

Hymer needed an RV component in a material on which logos and names could be 3D printed during the original production process itself. Extremely high printing precision to accurately reproduce often complex logos and name artwork, long-term deformation and fissuring resistance under harsh operating conditions, outstanding wear-resistant finishing and of course maximum process cost-effectiveness were the criteria for Forward AM to deliver a solution.

By identifying Ultrasint® TPU01 as ideal AM material for this mission; long-term structural integrity under persistently harsh real-world operating conditions thanks to excellent shock absorption, flexibility and elasticity to withstand vibration and eliminate deformation were guaranteed. Crucially for this specific application, Ultrasint® TPU01 delivers the print consistency and accuracy as well as thermal and UV stability required to print the edges and contours of highly detailed 3D designs – and keep them sharp after hundreds of thousands of miles on the road.

A further key advantage is that components printed in Ultrasint® TPU01 require a minimum of post-process finishing and bond easily with a wide range of specialized coatings and finishes. After 3D printing in Ultrasint® TPU01, the VisionVenture’s wheel arch liners are finished with the advanced Elastocoat C polyurea spray coating by BASF, which gives the liner and its unique, customer-specified design long-lasting protection from stains, scratches, and pebble impact damage.

Using Ultrasint® TPU01, Forward AM successfully 3D printed wheel arch liners for the VisionVenture that integrated bespoke customer logos and name artwork right from the OEM production process.

Interior Lamp

Also for the interior, the VisionVenture holds several 3D printed applications – such as wall hooks, furniture handles, a tablet holder or a hanging lamp in several designs.

The lamp housing as well as the lamp shade are 3D printed with materials from Forward AM – Ultrasint® PA6 FR polymer powder being the perfect fit as it is the first officially UL certified flame retardant PA6 powder for Laser Sintering (more information here). The lamp shade was printed with Ultrasint® TPU 88A – the flexible, translucent material opens up new possibilities for designers and interior stylists. Topping it off, the lamp shade features the flexible Ultracur3D® coating, in a specifically for this project developed color. By combining the high-performance materials smartly, a complex, illuminable geometry was achieved – resulting in a lamp that outshines the traditionally used ones in RVs.

Solution: Cost-effective appearance prototypes with high-performance materials

The success of the VisionVenture is great: it has already received the German Design Council’s highest accolade of “Best of Best” in the Automotive Brand Contest. At 2020’s European Innovation Award the VisionVenture was awarded in not just one but three categories: Interior Design, Exterior Design and Blogger’s Favourite. The VisionVenture was also one of the biggest visitor magnets at the 2019 K Trade Fair in Düsseldorf, Germany, the world’s premier showcase for the latest innovations in the synthetic industrial materials and fast-growing Additive Manufacturing (AM) sector.

More information about HYMER VisionVenture and BASF here.

Share this page

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!