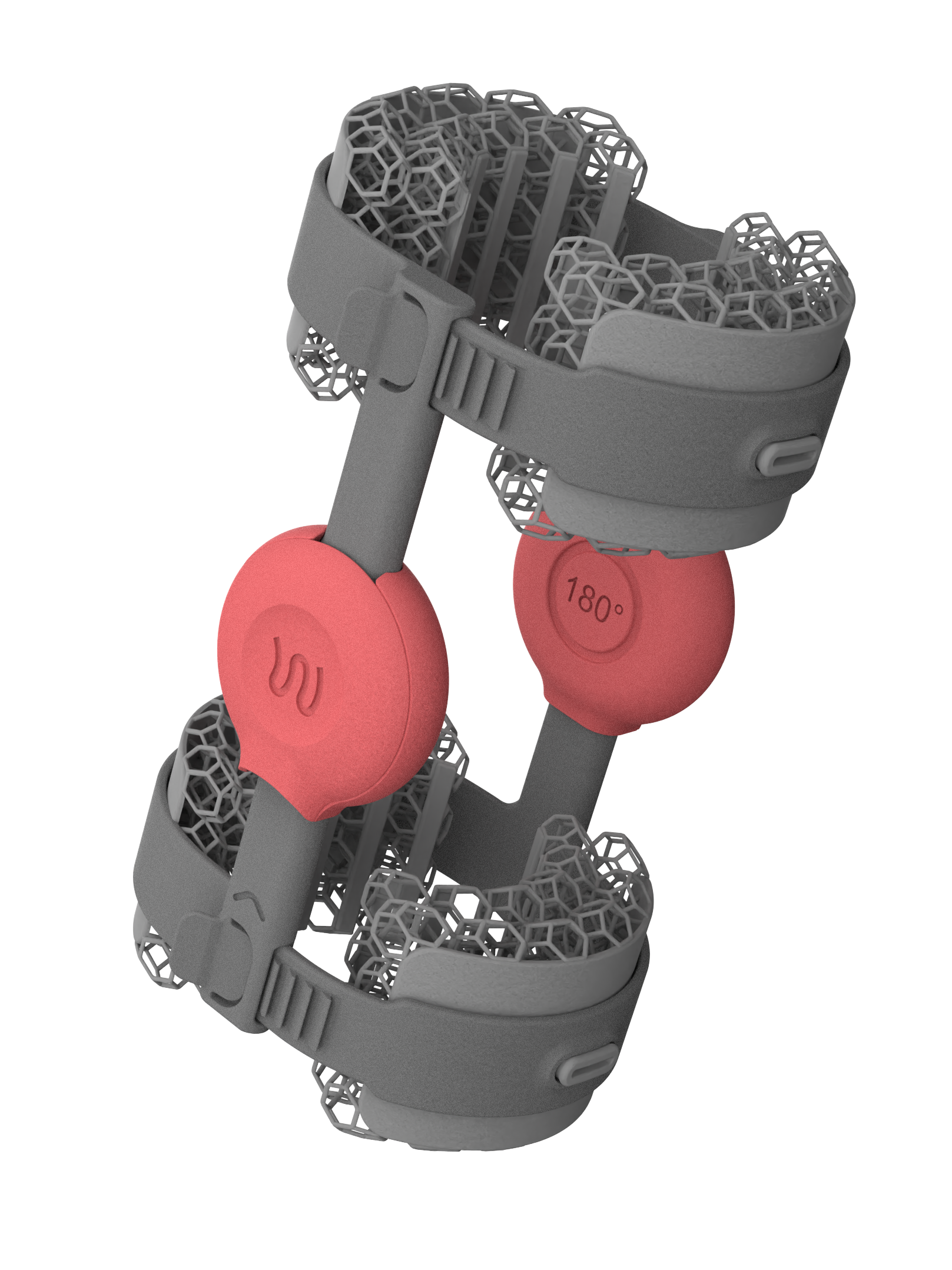

3D Printed Elastic Insert for Canine Orthosis Provides a Lightweight and Comfortable Solution for Recovery

Innovative material and the utilization of lattice structures provides an orthotic that fits snugly around a dog's limb, enabling customized fit and ensuring a comfortable healing experience.

Made from Ultrasint® TPU01, this lightweight and durable orthosis provides key advantages for canine recovery while being cost-effective, comfortable, and easy-to-clean. TPU01 is also certified to meet various regulatory standards including ISO 10993 for biocompatibility, ensuring it is non-toxic and safe for skin contact validating the material’s suitability for medical and veterinary applications.

Project Breakdown

Industry & Application

Healthcare, Orthosis for animals

Product

Ultrasint® TPU01

Partner & Technology

HP 3D Printing, MJF

Why Forward AM & TPU01?

Additive manufacturing allowed for the production of custom inserts designed specifically for each dog’s anatomy, ensuring safety with biocompatible and non-toxic materials.

BASF Ultrasint® TPU01 meets key regulatory standards like ISO 10993, confirming its non-toxicity and safety for skin contact.

Key Numbers

Wimba produced 500+ parts, reducing lead time from 6 weeks to 7 days.

Wimba, an innovative startup located in Krakow, Poland, is changing the landscape of the veterinary industry. Through the use of Additive Manufacturing, Wimba is 3D printing orthopedic products which are revolutionizing the field of customized orthopedic supplies allowing them to address degenerative, post-accidental, or congenital abnormalities in a way that is tailored to the specific needs of the patient.

This project, in partnership with Forward AM, focuses on the development of a 3D printed Elastic Insert for Orthosis, designed specifically to provide optimal comfort and support for dogs during their recovery from injuries. The insert is made from Ultrasint® TPU01, ensuring a lightweight and easily cleanable solution. The additional utilization of lattice structures provides key advantages with the ability to fit perfectly around the dog’s limb ensuring a glove-like fit and a healing experience that is both comfortable and secure.

The Challenge

Rethink the design and materials used for traditional orthotic devices — which are heavy, uncomfortable and difficult to clean — to both address product limitations and significantly decrease the discomfort dogs experience during their recovery process.

The Solution

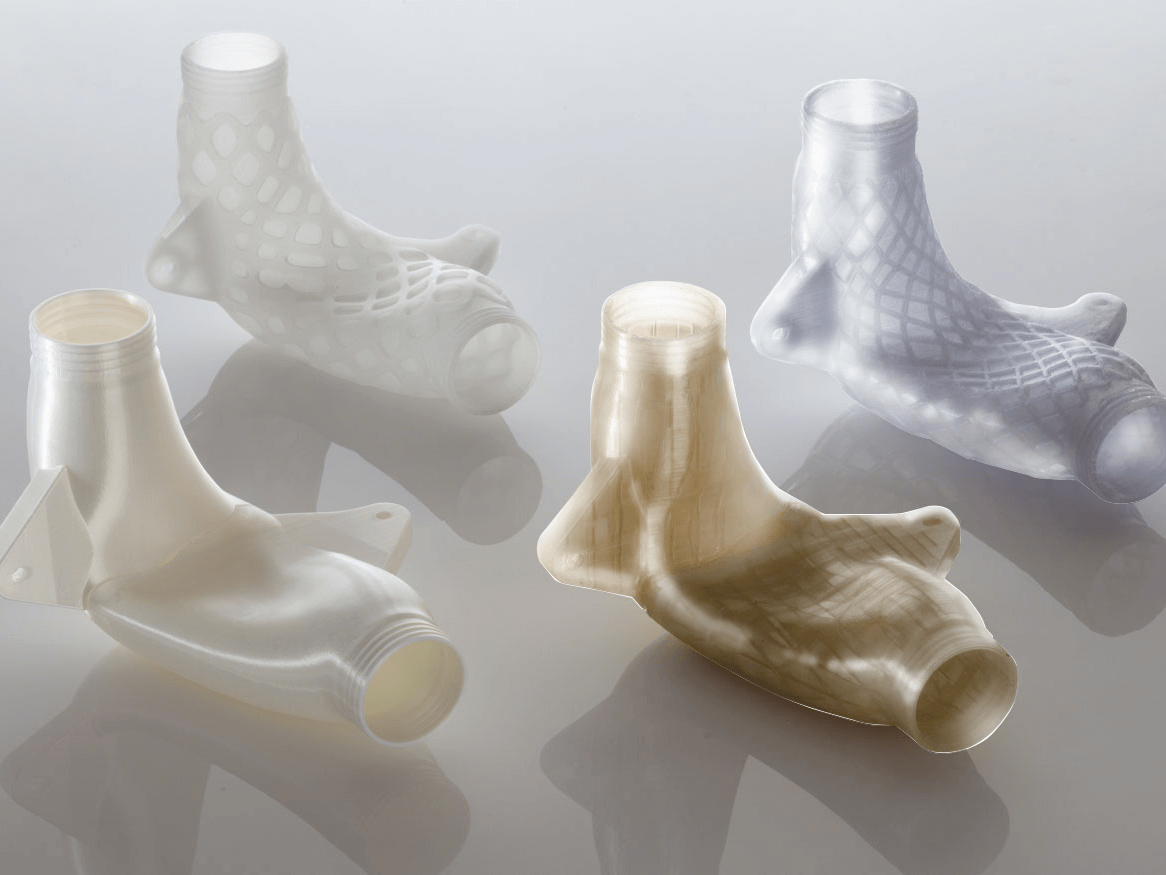

Through the utilization of Additive Manufacturing technologies, Wimba and Forward AM designed and produced an orthotic which would fit precisely around a dog’s limb, ensuring a healing experience that is both comfortable and secure. Creating an innovative design using Ultrasint® TPU01, this lightweight material offers flexibility and breathability therefore enhancing the overall comfort for the dog. The lattice structures used also reduce pressure points and allow for better airflow, preventing excessive sweating and potential skin irritations.

Another key advantage of using printed lattices with Ultrasint® TPU01 is the easy maintenance and hygiene it provides. The material’s smooth surface makes it simple to clean and sterilize reducing the risk of infection or complications during the recovery period. This feature is particularly crucial as dogs must spend time in outdoor environments and can easily encounter dirt and bacteria.

3D printing with Ultrasint® TPU01 offers customization and agility of production/iteration. The automated nature of the process allows for faster production, ensuring a timely delivery of the inserts needed to support the dog’s recovery. The lattice structures utilized also reduce the overall weight of the insert while enabling rapid prototyping allowing for quick iterations and adjustments based on specific dog requirements.

Multi Jet Fusion (MJF) technology was chosen as the production method for the elastic insert for the orthosis due to its ability to create customized designs with high precision. This allows for a tailored fit to the unique anatomical features of each dog thus enabling efficient prototyping and on-demand manufacturing capabilities. By utilizing Ultrasint® TPU01 and MJF technology, the Elastic Insert for Orthosis is certified to meet various regulatory standards including ISO 10993 for biocompatibility, ensuring it is non-toxic and safe for skin contact. These certifications validate the material’s suitability for medical and veterinary applications and provide complete assurance for its use in orthotic devices.

The Result

Wimba’s Elastic Insert for Orthosis made with BASF Ultrasint® TPU01 material offers a cost-effective, comfortable, and easy-to-clean solution for supporting dogs in their recovery from injuries. By utilizing the lattice structures available through 3D printing technologies, the insert can be customized to fit the unique anatomical features of each dog creating a tailored design specific to each dog’s limb. The lightweight nature of the insert significantly reduces the strain on a dog’s limb, allowing for enhanced mobility and improved overall comfort.

By addressing the limitations of traditional orthotic devices, Additive Manufacturing allows Wimba to offer a device which enhances mobility, reduces discomfort, and promotes a more efficient and comfortable healing process for each individual and beloved canine companion. In addition, the number of hours to produce a custom orthotic is reduced from six weeks to seven working days. This provides not only a cost savings through reduced manufacturing complexity and increased efficiency but also enables on-demand production and customization capabilities.

The 3D printed Elastic Insert for Orthosis from Wimba represents a significant advancement in the field of veterinary medicine. By providing dogs with a comfortable and supportive orthotic solution, it not only aids in their recovery but also improves their overall well-being during the rehabilitation process. The customization and easy maintenance of the insert further contributes to its practicality and effectiveness as a canine recovery tool. Additive Manufacturing enables the precise deposition of material, resulting in minimal waste during production therefore reducing material costs and contributing to a more sustainable manufacturing process.

“Additive manufacturing was the right decision for our project as it allowed us to create highly customized, lightweight, and comfortable elastic inserts using Forward AMs Ultrasint® TPU01, ensuring optimal support and a tailored fit for dogs during their recovery. By leveraging Forward AMs Ultrasint® TPU01 in combination with the MJF technology, we have achieved a completely new level of comfort for canine recovery.”

Franek Kosch, Co-Founder and Managing Director at Wimba

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!