Unlocking Additive Manufacturing for food-contact Parts

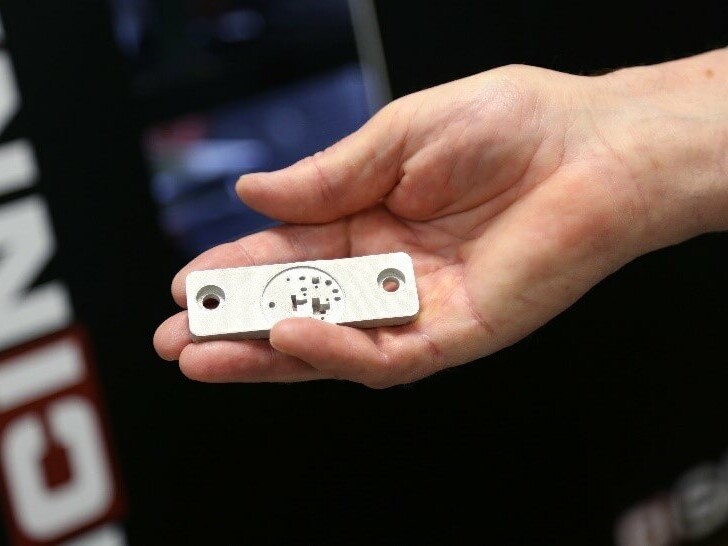

End-to-end 3D printing process to produce components safe for food

The unparalleled possibilities of Additive Manufacturing are compelling to countless industries – food-related applications are certainly no exception. So far, leveraging Additive Manufacturing for food-safe parts was challenging to realize as the highest requirements to protect human health have to be met.

Project Breakdown

Industry

Consumer Goods

Why Forward AM?

Perfect-fit material Ultrafuse® PET, Additive Manufacturing expertise

The result

Manufacturing process for food-safe parts

The safety of food contact materials needs to be very strictly evaluated to ensure that chemicals do not migrate from materials into food. The materials must be manufactured in full compliance with EU regulations, including Good Manufacturing Practice, so that any potential transfer does not raise food safety concerns, impact the desired composition of the food, or have adverse effects on its taste and odor. To comply with these requirements, special processes and measurements were implemented in Forward AM’s filament production to avoid any risk of cross contamination. Parts printed with Forward AM’s filament Ultrafuse® PET were tested accordingly to LFGB and Regulation (EC) No. 1935/2004 and met the requirements for food contact.

Certainly the material used needs to be food-safe, but this is only one half of the story: the whole manufacturing process has to fulfil highest requirements to protect human health. To be able to produce end parts approved for food contact use, the entire manufacturing process must be considered – from material production, through the 3D printing process, to the final end part and its packaging.

Miele, German premium domestic appliance manufacturer was looking for a way to produce several household accessories at lean ramp-up costs – with Additive Manufacturing, Miele is able to quickly enter the market and produce high-quality accessories on-demand in small series numbers. Together with Replique, start-up of Chemovator GmbH, and printer manufacturer BCN3D, the experts at Forward AM created the first manufacturing process for food contact with 3D printing. Watch the video and see what’s behind!

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!