Fixtures for Danish Design Faucets

How Danish Design Leader VOLA Is Tapping into Additive Manufacturing for Top-end Tooling

Leading Danish design brand VOLA is prized for high-end taps and interior fixtures that beautifully express Scandinavian taste and style.

Project Breakdown

Industry

Industrial

Material/Product

Ultrafuse® PET

Why Forward AM?

High-performance material as perfect fit

The result

Time- and cost-effective tool production

Flanking their exquisite hand-craftmanship and design expertise with new technologies, VOLA have introduced Additive Manufacturing in their production process. Let’s take a look what’s behind this – and how they have already achieved very significant time and cost savings.

Challenge: Producing strong tools while saving cost and time

VOLA are continuously developing and testing new products, as improving their assembly line tooling is key to ensuring the latest technology pays into their upmarket product range. This is where Additive Manufacturing (AM) comes into play, along with the advanced Ultrafuse® PET filament by Forward AM. VOLA traditionally relied on milling to produce their tools in steel, aluminum or plastics – a very time and cost-intensive process that required a highly skilled workforce. Sometimes even an external specialist firm to produce the CAD-designed tools.

Solution: 3D Printing with Ultrafuse® PET for fast, cost-effective tool production

This lengthy procedure can be shortened very significantly with the aid of Additive Manufacturing, whose digital technology opens up possibilities of creating shapes that are impossible with conventional production techniques.

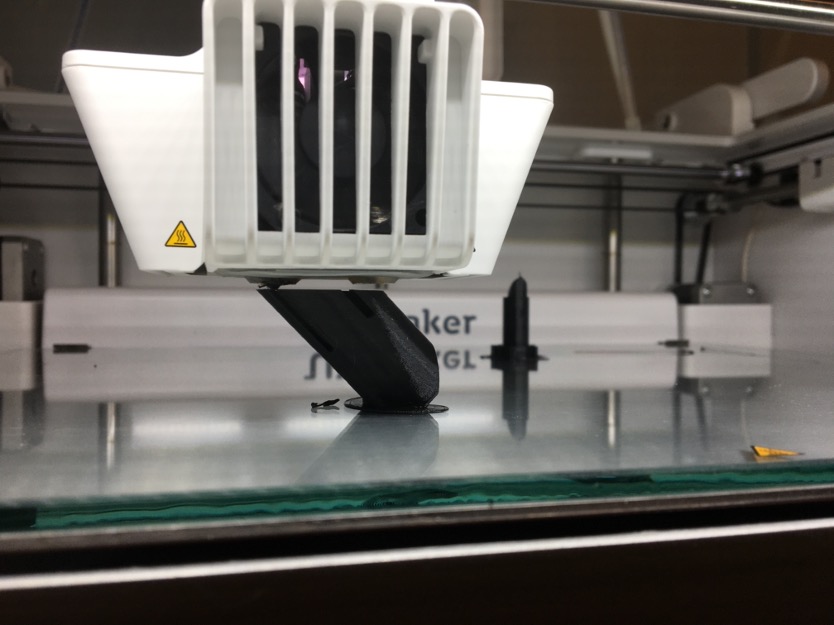

Harnessing the benefits of Additive Manufacturing, VOLA started to “think additive” – and identified the perfect material together with Forward AM: Ultrafuse® PET. Delivering outstanding dimensional stability, toughness and high temperature tolerance. This advanced 3D printing material is the ideal choice for VOLA’s requirements. The tools had previously been milled in aluminum, industrial-grade plastics or steel to ensure the high strength vital in the machine-tool assembly process. Ultrafuse® PET by Forward AM is more than a match for this challenge.

By switching to AM, VOLA is now able to create all different kinds of tools in-house – much faster than before, and at a fraction of the previous cost. (Overall, VOLA is now manufacturing 10 percent of all tools additively instead of traditional milling.)

“We received our first 3D printer and Ultrafuse® PET spools from Forward AM at noon – and overnight, we printed 20 small sensor fixtures for our robot tools. It was an instant success! From now on we will consider Additive Manufacturing as a first-line option wherever possible.”

Dennis Brødbæk, Product & Process Innovation, VOLA

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!