Making Mass Personalization Possible: Forward AM and Toolkit 3D Create End-to-End Solutions

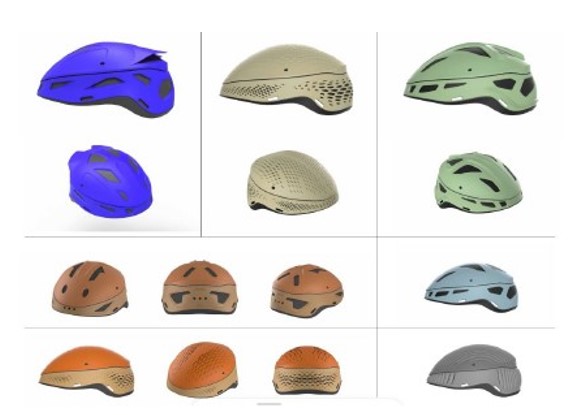

Collaboration makes it easy for consumers to get made-to-fit products like custom bicycle helmets.

Ultrasint® TPU, one of Forward AM’s many high-performance 3D printing materials, is used to produce the strong, flexible, and lightweight lattice for custom helmets. In addition to supplying the material solutions that innovators need, Forward AM helps optimize lattice structures while bringing different solutions, such as easy ordering, together.

Project Breakdown

Industry & Application

Consumer Goods, Sporting Goods

Product

Ultrasint® TPU01

Partner & Technology

HP 3D Printing, MJF

Why Forward AM & TPU01?

Additive manufacturing allowed for the production of made-to-fit bicycle helmets that combine comfort and protection.

Forward AM Ultrasint® TPU01 meets key regulatory standards like ISO 10993, confirming its non-toxicity and safety for skin contact.

Key Numbers

The entire integration process took less than two weeks to perfect.

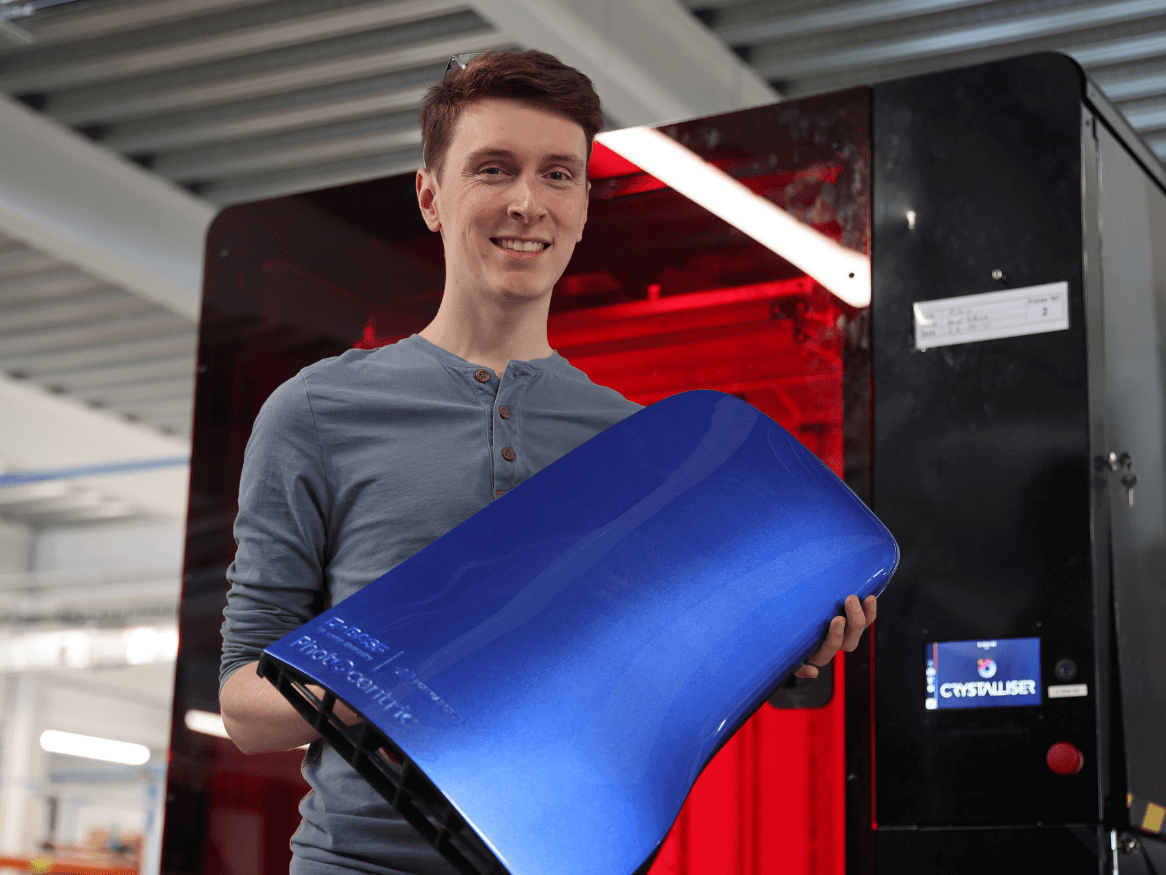

Toolkit3D of Seattle, Washington (USA) has developed a cloud-based platform that integrates laser scanning, product design, and order management with subtractive and additive manufacturing. Customizable workflows support personalization at mass-production speeds and volumes.

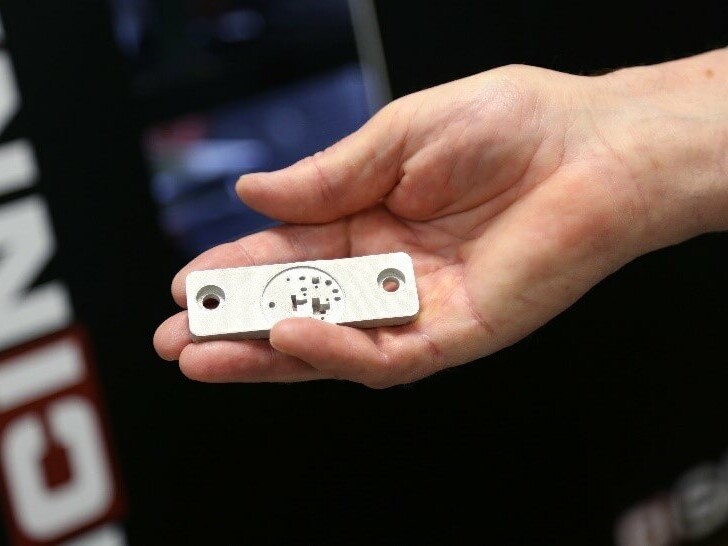

In partnership with Forward AM, Toolkit 3D developed a streamlined way to 3D-print bespoke bicycle helmets. The lattice uses Ultrasint® TPU01, a thermoplastic polyurethane (TPU) powder for HP Multi Jet Fusion (MJF) printers. In addition to supplying this versatile material, Forward AM leveraged its deep experience in lattice design to optimize TPU01’s usage.

The Challenge

Toolkit3D wants to make mass personalization possible for any product. For bicycle helmets, that means giving consumers the ability to scan the dimensions of their heads, choose shell colors and a texture, and order bespoke products with ease. The company also wants manufacturers to use the results of laser scans to 3D-print custom lattices that fit standard-sized bicycle helmets.

To prove the use case for mass personalization, Toolkit3D needed the right partners. Software from nTop generates lattices; however, lattice optimization is also about material selection and design optimization. With bicycle helmets, a lattice needs a material that’s strong, flexible, lightweight, and impact-resistant. Comfort and breathability are also important because the lattice contacts the bicyclist’s head.

As part of a larger assembly, the lattice must accommodate the shell’s ledges, clips, and straps. Prototype shells can be 3D printed, but production-quality shells are molded. Toolkit3D wanted to secure 3D printed and molded pieces without gluing and to assemble helmets with modular, swappable parts so that consumers could also use them for other sports-related activities.

The Solution

Forward AM used Toolkit 3D’s Scan-to-Fit Design Engine to produce a helmet that was built-to-fit using precise head measurements. Along with one of the world’s largest portfolios of high-performance 3D printing materials, Forward AM excels at bringing different solutions together. Deep experience in lattice design, prototyping, finishing, and testing adds value to customer projects.

During the design process, Forward AM helped optimize the lattice structure to make the most of Ultrasint® TPU01. This lightweight, flexible, and easy-to-print material combines strong, durable performance with excellent surface quality. It’s a dependable choice for sports protection applications that require shock absorption and is designed for HP 5200 MJF printers.

Forward AM’s deep experience in lattice design optimized the use of these repeating 3D shapes and helped designers increase comfort and reduce weight while improving cushioning, rebound, and aeration. As Toolkit3D discovered, Forward AM’s expertise also supports the use of 3D printed components within assemblies with other parts.

The Result

Together, Forward AM and Toolkit3D created an end-to-end solution that makes mass personalization possible for any product that can be scanned and customized. Forward AM’s Ultrasint® TPU01 is easy-to-print and Toolkit3D’s ordering system is easy-to-implement.

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!