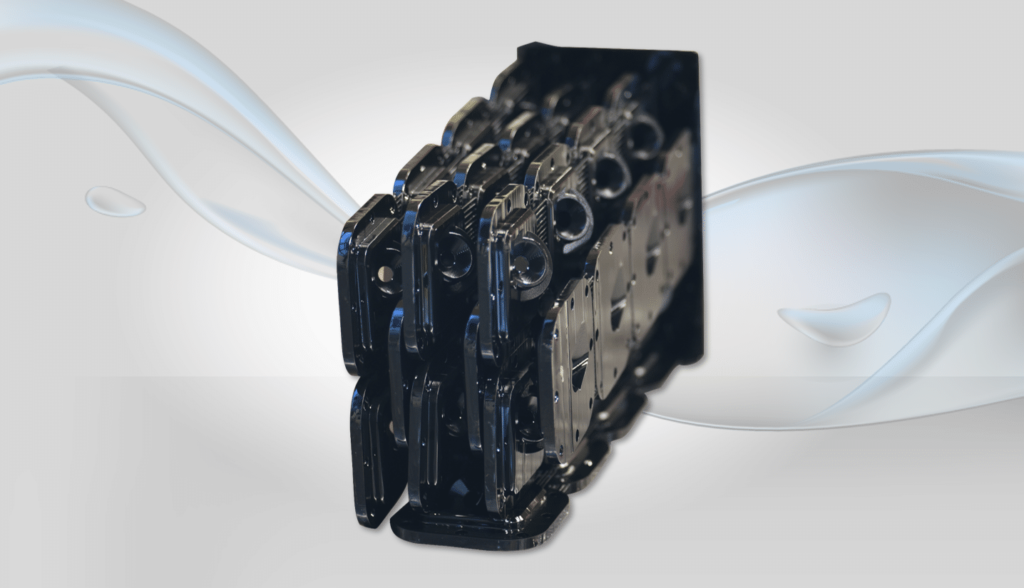

Camera Housing

Forward AM for Origin: Ready for Additive Mass Production

At first glance, it seems to be a pretty small part – but in fact it’s tremendously important, as it contributes to bringing Additive Manufacturing closer to industrial scale.

Table of Content

- Project Breakdown

- Pushing the envelope: Photopolymers built for volume, priced for scale

- How does Forward AM come into play?

- Challenge: Producing a functional AM part at scale – and at low cost

- Ultracur3D® ST 45 B – Engineering Plastics product line

- Benefits of Ultracur3D® ST 45 B at a Glance

- Next Steps

Project Breakdown

Industry

Consumer goods

Project

Camera housing | perfect fit photopolymer material

Why Forward AM?

End-to-end solution from design to production

Forward AM materials used

Ultracur3D® ST 45 B

The result

Production of functional AM part at high volume and low cost

Pushing the envelope: Photopolymers built for volume, priced for scale

Curious to know what we’re talking about? Read on – and find out about our breakthrough project with Origin! In May 2019, Origin, the developer of the leading open platform for additive mass production, revealed Origin One – an SLA/DLP printer specifically created for large-scale production. It features a build volume of 192 x 108 x 350 mm with an open material platform, modular hardware, and specialized software to automate the printing process. Equipped with 4k lithography and a native resolution of 50 μm, the Origin One ensures optimal resolution and a flexible polymer process.

The Origin One uses the company’s Programmable Photopolymerization (P3) technology to turn materials into isotropic parts and products ready for end-use. It makes precise orchestration of light, temperature and other conditions possible, allowing real-time optimization and ensuring best possible results in consistent batches. In short: The Origin One allows scalable production at a reasonable cost – a big step towards the industrialization of AM.

How does Forward AM come into play?

As is so often the case, the devil is in the details – here it’s in the cameras that are required to bring the mentioned P3 technology to life. The Origin One features several integrated cameras for computer vision and to capture data in infrared light range. Additional sensors measure other environmental conditions during the 3D print process – helping to ensure quality and accuracy. Mounting these cameras to the printer was found to be quite complex.

Challenge: Producing a functional AM part at scale – and at low cost

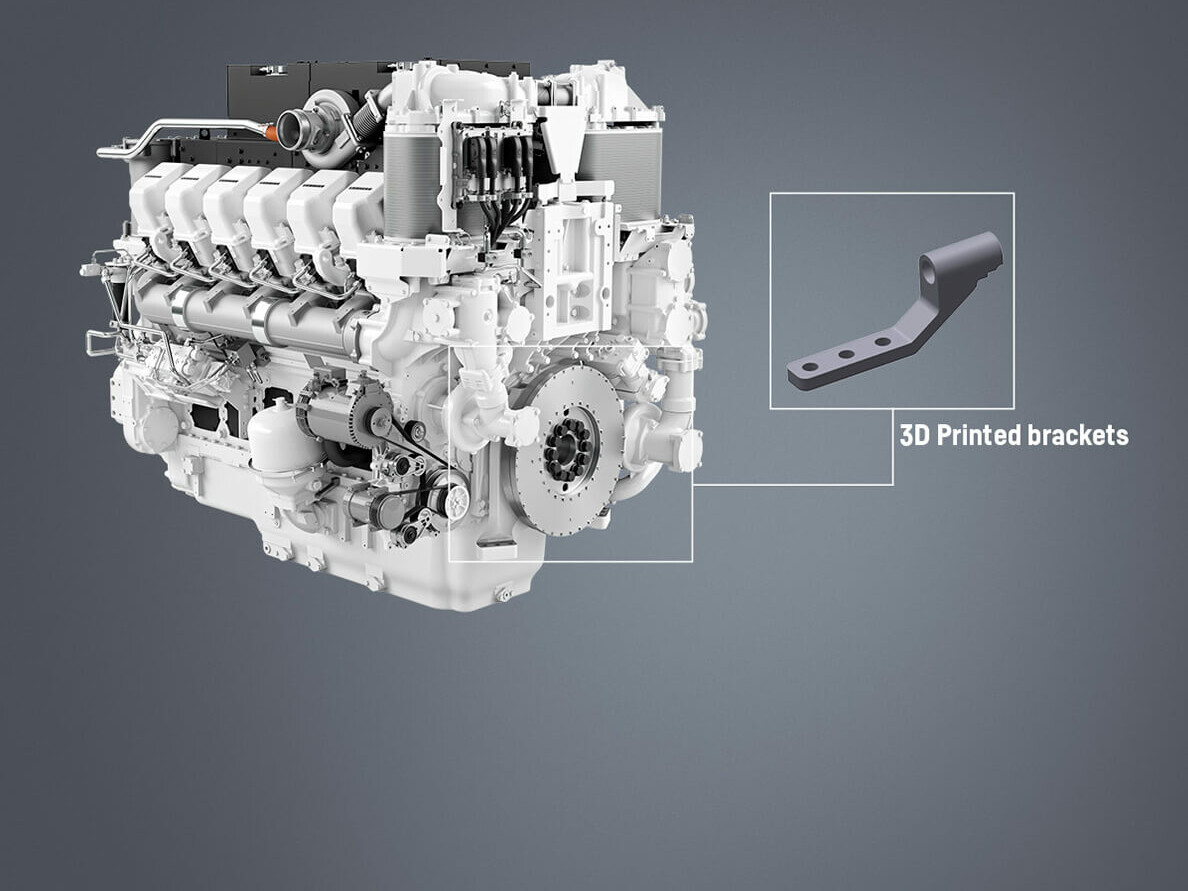

Matt Miyamoto, Design Engineer at Origin, first designed the camera mounts by CNC machining black ABS plastic. While working on it, he encountered an issue: A compound angle meant that the part could only be machined by a 5 or 3-axis CNC with multiple setups. This made the camera housing parts expensive to machine at both low and high volumes. In fact, too expensive to produce them at all. Once the problem was identified, it was likely that Origin would need to explore the solutions AM could offer. And the solution came in the form of Forward AM’s Ultracur3D® ST 45 B.

Ultracur3D® ST 45 B – Engineering Plastics product line

Ultracur3D® ST 45 B is a medium-viscous, highly reactive photopolymer for 3D printing applications resulting in tough multipurpose parts. It can be used to produce high performance functional parts by using Stereolithography (SLA), Digital Light Processing (DLP) or Liquid Crystal Display (LCD) machines. When it comes to post-processing, Forward AMs Ultracur3D® ST 45 B enables optimal surface finish, mechanical strength and high throughput.Ultracur3D® ST 45 B can fulfil the requirements of functional applications regarding high accuracy and mechanical strength, where existing 3D printing materials often show limitations. In a nutshell:Ultracur3D® ST 45 B proved to be a perfect fit for the Origin One, supporting the high throughput and thus enabling mass production.

Benefits of Ultracur3D® ST 45 B at a Glance

- For tough multipurpose parts

- Can be used with SLA, DLP & LCD machines

- Optimal surface finish

- High throughput & mechanical strength

Coming back to Origin: By packing the parts into the build volume they were able to print 40 camera housings in a single print, taking less than 8 hours. Printing overnight enabled maximum printer utilization, and after repeating the same print the following morning, the order of 100 camera housings was completed in under 24 hours. Post-print, a simple solvent wash followed by a one-minute UV post-cure rendered the parts ready for use. By using Ultracur3D® ST 45 B, Origin was able to produce 100 finished camera mount housing parts – all within 24 hours, at a fraction of traditional manufacturing cost.

Looking at the above method comparison: Across the board, combining Origin’s process with Forward AM’s Ultracur3D® ST 45 B material proves to be the most cost-effective way to produce these parts while achieving optimal results. By merging both competencies – Origin’s P3 technology and Forward AM’s Ultracur3D® ST 45 B – we were able to deliver a compelling solution, enabling the Origin One to break ground for AM industrialization.

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!