The First Fully 3D-Printed Orthopaedic Shoe Worn at OTWorld in Leipzig

Ultrafuse® TPU enables flexible properties – and processes!

High-quality orthopaedic footwear is essential for treating certain foot problems without surgery.

This specialized footwear is traditionally crafted by skilled pedorthists using manual techniques – a labor-intensive process using skills which take many years to master. These skills are also in decline, as fewer young people choose to enter the field.

Project Breakdown

Industry & Application

Medical Footwear

Product

Ultrafuse® TPU 85A | Ultrafuse® TPU 64D

Partner & Technology

Fused Filament Fabrication (FFF)

Why Forward AM?

Fast-printing TPUs with good abrasion resistance and biocompatibility

Key Result

The first fully 3D-printed orthopedic footwear debuted at the prestigious OTWorld trade show and World Congress in Leipzig

Daniel Petcu’s pioneering work with 3D printing and Ultrafuse® TPU materials has set a new standard in orthopaedic footwear. By integrating digital design and production processes, he’s shown it’s possible to create fully 3D-printable medical footwear that’s not only functional and durable but also stylish and comfortable. This innovation has the potential to make high-quality, personalized medical footwear more accessible than ever before.

The Challenge

Design and Produce Functional, Stylish Medical Footwear That Overcomes Traditional Design Limitations

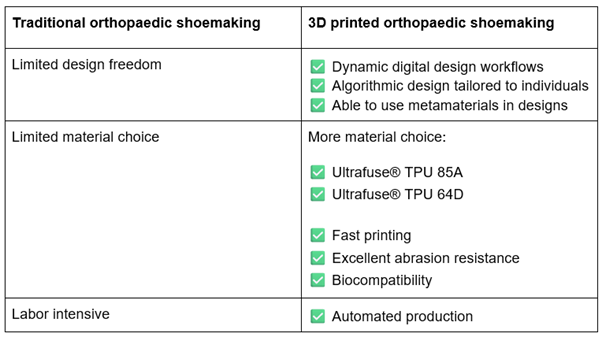

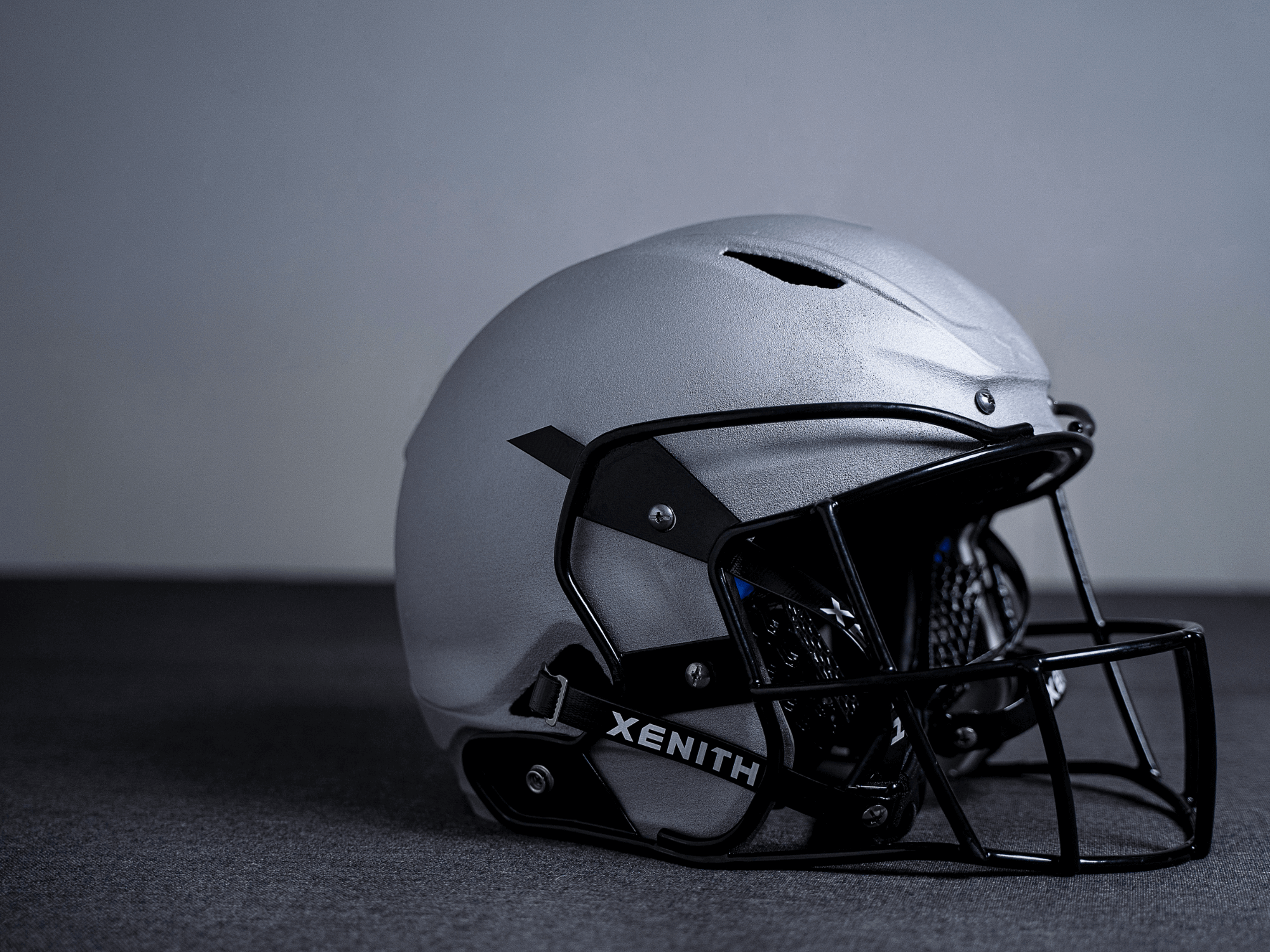

Traditional techniques and materials used to make orthopaedic footwear have limited design freedom. While the results are functional, they usually lack style, making some patients reluctant to wear them.

Each year, industry trade shows and summits highlight emerging technological advancements, but all of these tend to focus on individual components instead of the whole shoe – for instance, orthotics and shoe lasts.

The Solution

Additive Manufacturing with Ultrafuse® TPU

This is where 3D printing steps in as a true innovation. Unlike traditional orthopaedic shoe making methods, 3D printing automates the entire production process, and enables a fully integrated digital workflow. This reimagines the design and production of medical footwear from the ground up.

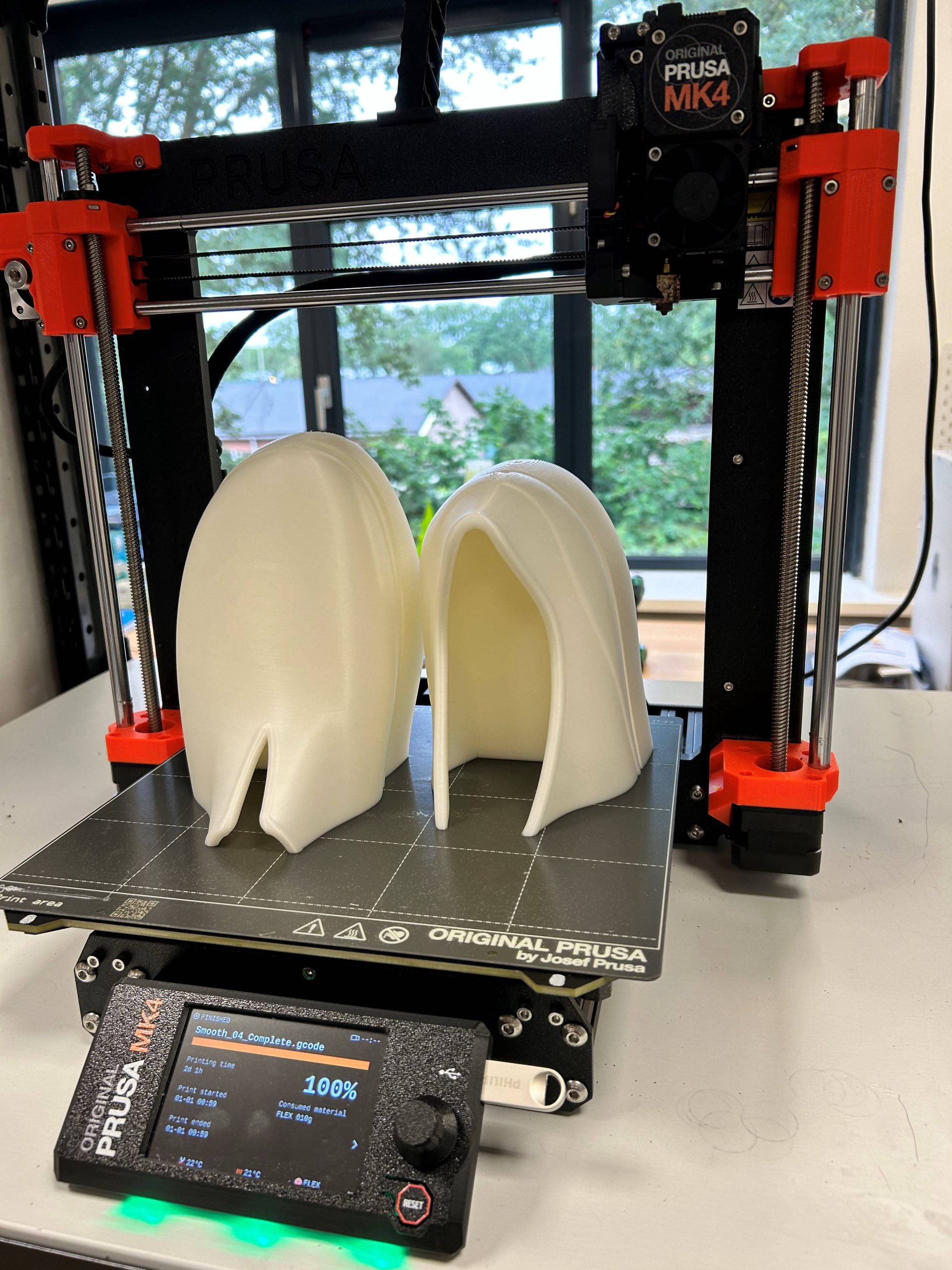

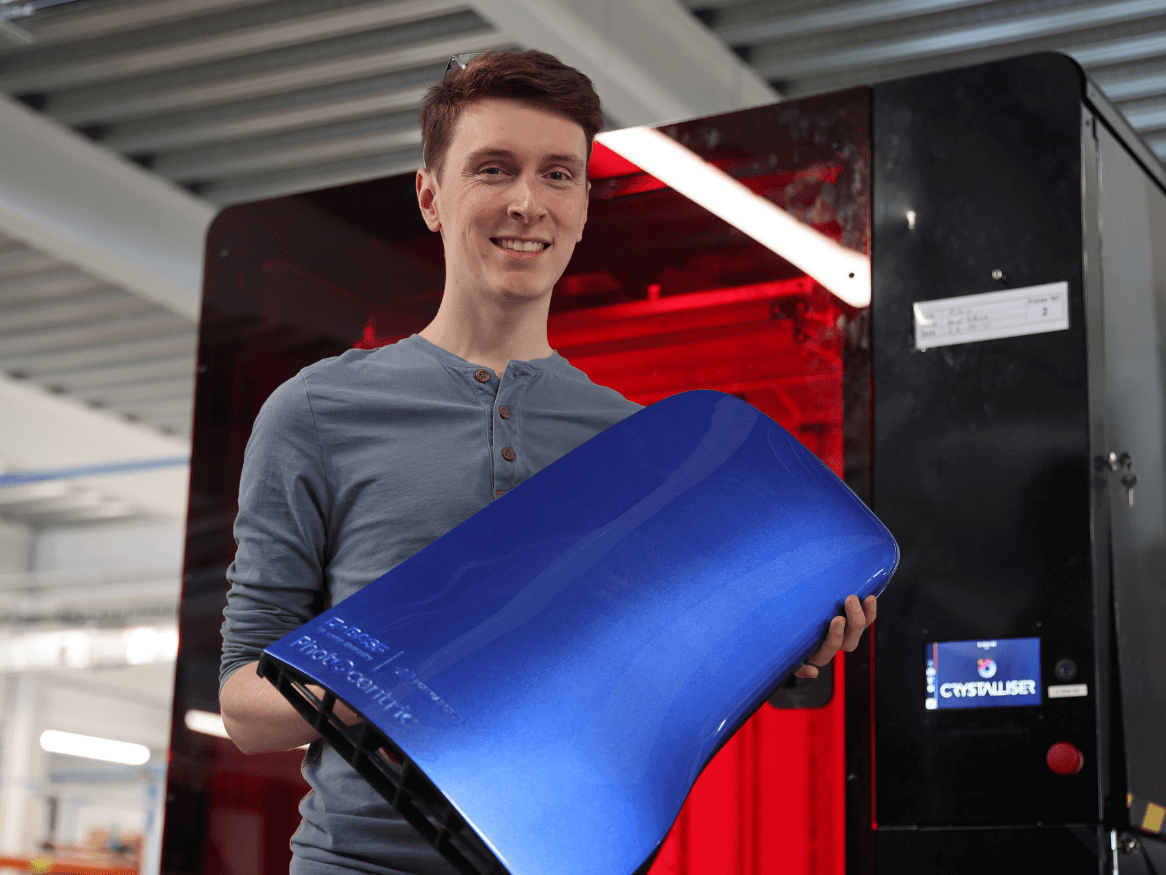

Daniel Petcu, a footwear engineer with a PhD in foot orthoses, recognized the potential of 3D printing early on. After experimenting with a Prusa MK3S printer, he decided to shift his company, Pedorthic Art, to focus exclusively on 3D printing. This decision was driven by the advantages offered by Fused Filament Fabrication (FFF) 3D printing, particularly the automation of the manufacturing process and the unparalleled design flexibility it enables.

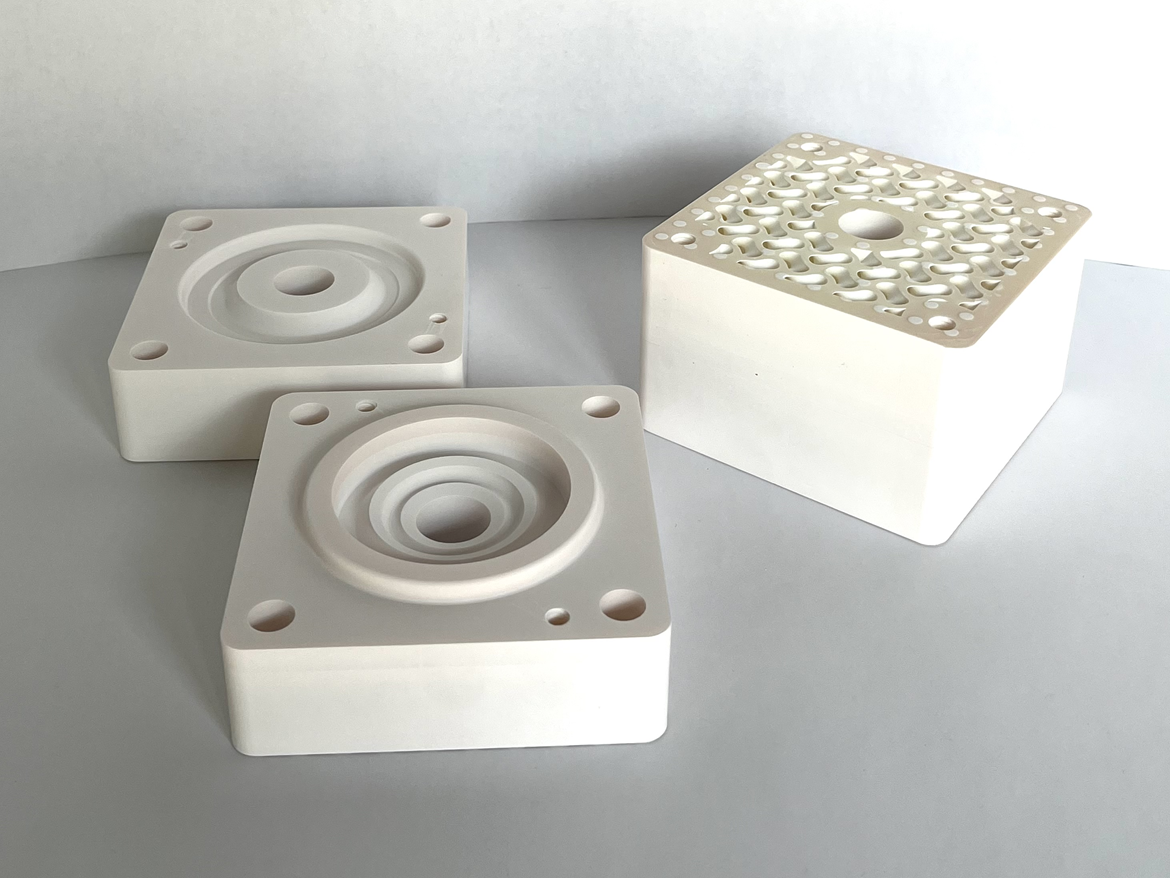

With 3D printing, new design options become possible, including the use of metamaterials – internal structures with properties that traditional methods simply cannot achieve.

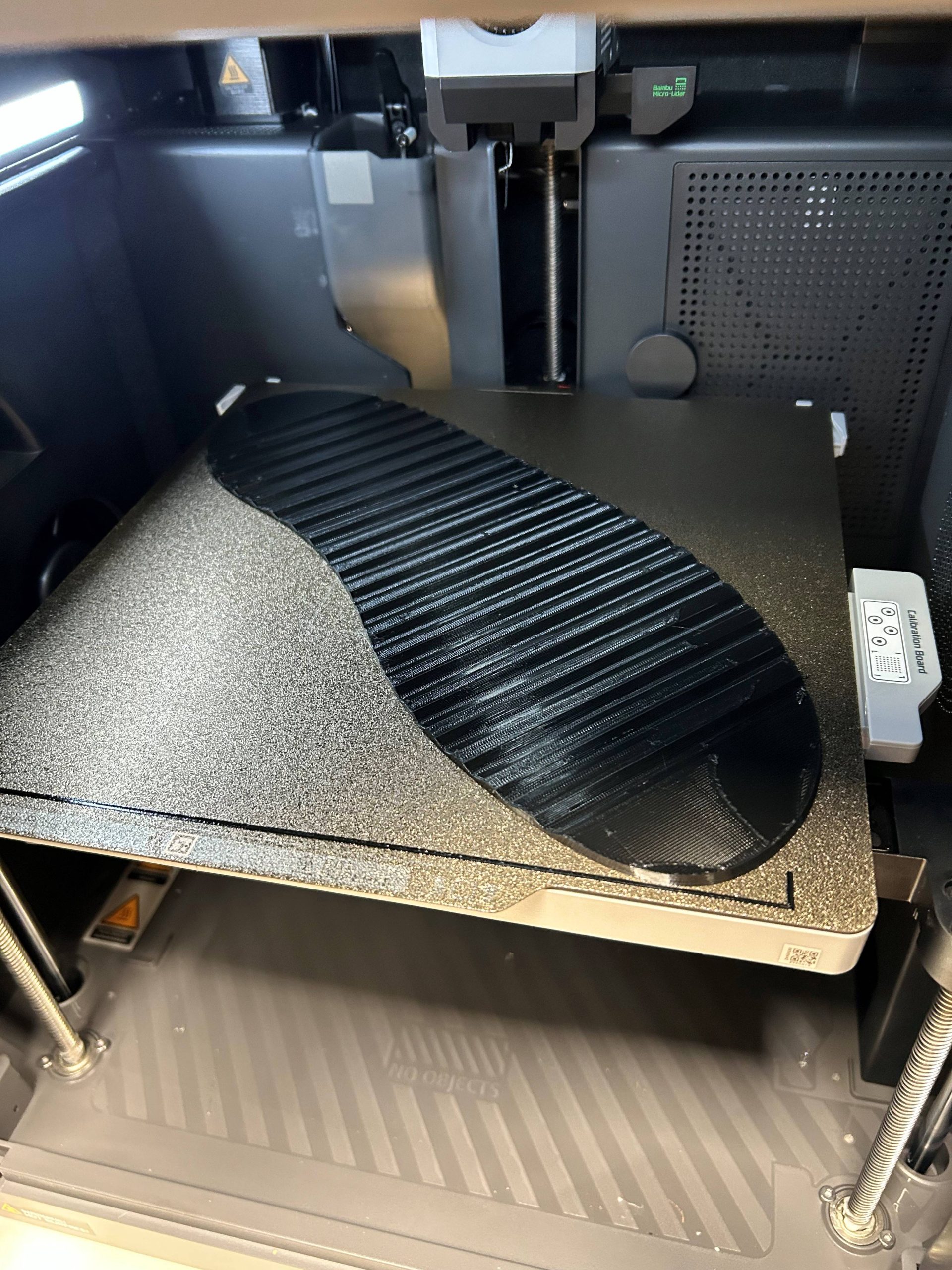

Inspired by The Perfect-Fit Climbing Shoe, Daniel designed and produced the first fully 3D-printed orthopaedic footwear, which he wore at OTWorld in Leipzig. Flexible 3D printing materials like Ultrafuse® TPU 85A and TPU 64D were ideal choices for the application, enabling fast printing, excellent abrasion resistance, and compliance with medical device safety regulations thanks to their biocompatibility.

Re-Imagining Orthopaedic Footwear Design and Production

The development of this fully 3D-printed orthopaedic shoe involved several key stages:

1. Pedorthic Information Modeling Concept

Using the Pedorthic Information Modeling (PIM) concept, which is based on parametric design principles, Daniel was able to manage the complex variations in design parameters effectively, ensuring that every aspect of the shoe met the specific needs of the patient.

2. Parametric Thinking and Design

Using custom-designed, algorithm-based CAD software like Rhino and Grasshopper, Daniel was able to create a highly detailed digital model of the shoe. This parametric and algorithm-based 3D modeling ensured that the final product would be both functional and aesthetically pleasing. It also meant that basic inputs could be adjusted to tailor the design to another patient, without the need to manually design an entirely new shoe.

3. Designing, Printing, and Testing

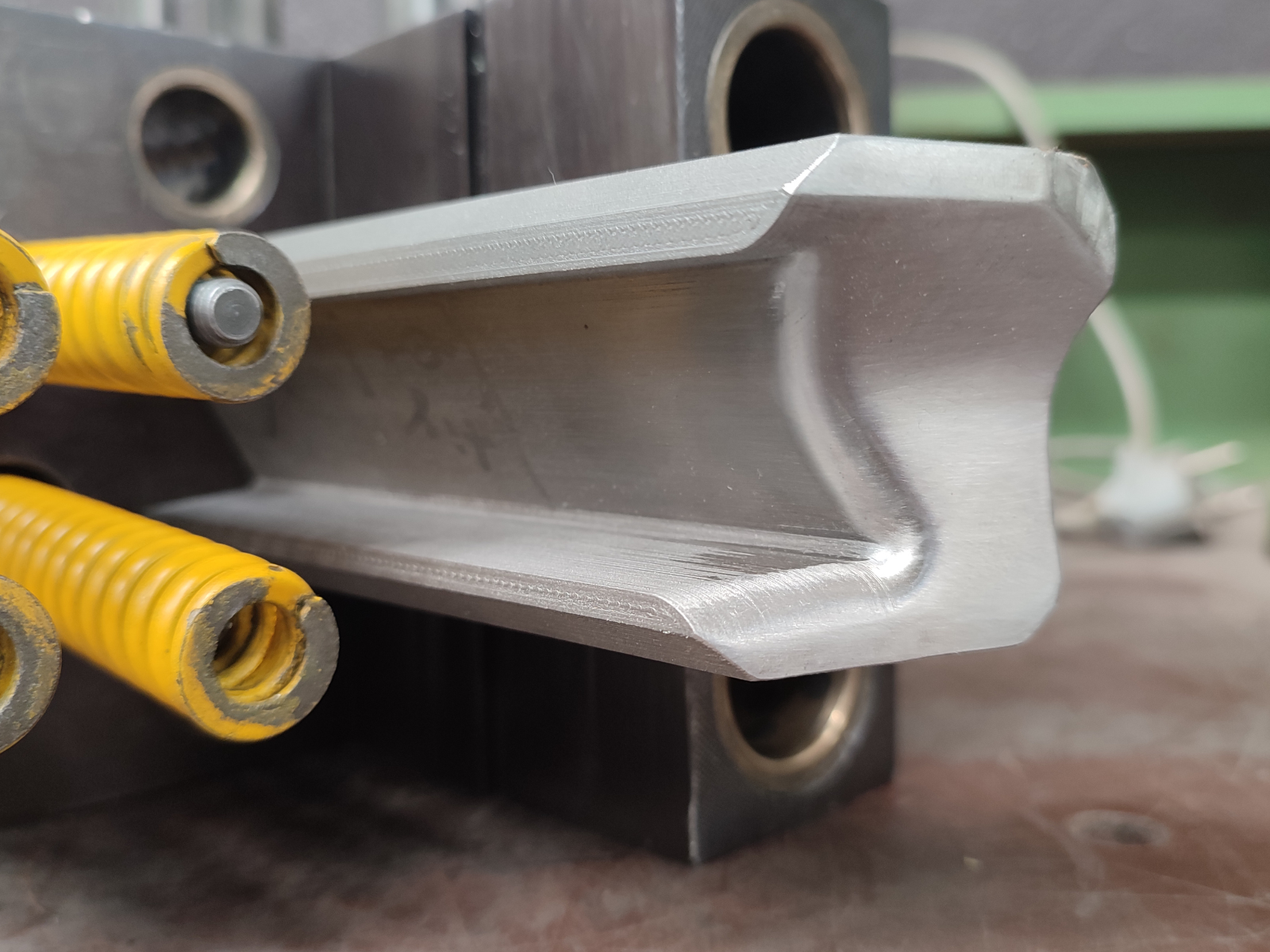

The shoe was designed as a single part, integrating both the upper and midsole into one cohesive unit. This design not only streamlined the manufacturing process but also enhanced the structural integrity of the shoe. A particular focus was placed on designing an ‘infill-based’ rocker bottom shoe, which is crucial for patients with specific conditions like bilateral ankle rigid equinus. The flexibility and durability of the shoe uppers, with a thickness of 5 mm, were thoroughly tested to ensure they met the necessary wearing comfort.

4. Leveraging Ultrafuse® TPU Materials

Ultrafuse® TPU 85A and TPU 64D were integral to the success of this project. These materials provided the perfect balance of flexibility and durability, essential for creating a shoe that could withstand daily wear while maintaining comfort. The biocompatibility of Ultrafuse® TPU ensured that the shoe was safe for prolonged contact with the skin, meeting stringent medical device regulations. They also could be 3D printed at above-average speeds, streamlining the production process.

The Result

A Custom, Functional, Stylish Shoe with a Streamlined Production Workflow

Using 3D printing technologies to design and create orthopaedic footwear offers significant advantages over traditional methods:

- Complete Customization: 3D printing allows for precise customization tailored to the unique needs of each patient, resulting in a perfect fit and enhanced comfort.

- Design Flexibility: The ability to create complex, intricate designs – such as those incorporating metamaterials – opens up new possibilities for improving both the functionality and aesthetics of medical footwear.

- Streamlined Production: 3D printing automates much of the production process, reducing the time and labor involved, while also minimizing the potential for errors.

- Material Innovation: Ultrafuse® TPU materials offer superior durability, flexibility, and biocompatibility, making them ideal for medical applications.

- Patient Involvement: Patients can be more involved in the design process, choosing colors, textures, and other aesthetic details, which increases their satisfaction and likelihood of wearing the footwear.

- Cost Efficiency: The overall process is more cost-effective, thanks to reduced labor costs, material waste, and the need for rework.

“I often receive private messages from others in the field with questions or comments about how my approach has motivated them. It brings me joy when people share images of their progress with me!”

Daniel Petcu, Pedorthic Art

We’re ready to support your project with additive manufacturing – simply get in touch with one of our expert team members today!

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!