3D-Printed Tools for Low-Volume Injection Molding

Collaboration overcomes traditional limitations and provides one-day turnarounds on accurate tools for production-quality parts.

Becton-Dickinson uses Forward AM’s Ultracur3D® RG 3280 ceramic-filled resin with Axtra3D’s Lumia X1 3D printer to rapidly produce low-volume injection molds for accurate, easy-to-eject parts made of different plastics.

Project Breakdown

Industry & Application

Medical, Healthcare

Product

Ultracur3D® RG 3280

Partner & Technology

Axtra3D’s Lumia X1 3D Printer

Why Forward AM Solutions and Materials?

Forward AM supplied the material and support needed to 3D-print rapid, accurate tooling.

Key Numbers

Molded 30+ polypropylene parts for manual ejection and molded 100+ polypropylene and 100+ polycarbonate pieces for automatic ejection.

Becton Dickinson of Franklin Lakes, New Jersey (USA) is the world’s largest manufacturer and distributor of medical surgical products. To support its partners, the medical technology company provides low volumes of parts for tradeshows, materials testing, and product assembly. Often, the partner requests are urgent.

In partnership with Forward AM and Axtra3D, Becton Dickinson used additive manufacturing to quickly produce injection molds with production-level quality. In addition to supplying Ultracur3D® RG 3280, a ceramic-filled polymer, as the mold material, Forward AM shared its 3D printing expertise.

The Challenge

Plastic parts for medical applications can be injection-molded, but the tools that are used for low volumes can be expensive and take a long time to make. Traditionally, low-volume injection molds have also lacked the precision that’s needed to create production-quality components.

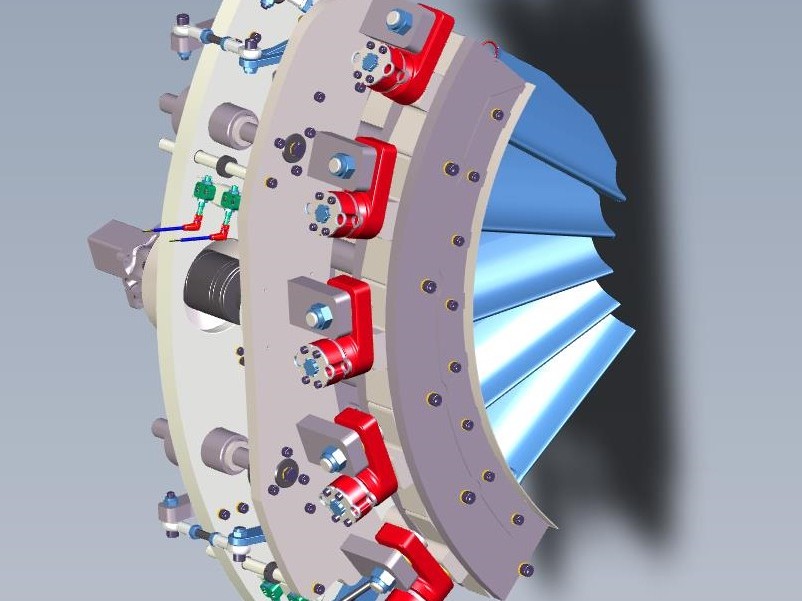

To reduce costs and accelerate mold-making, master unit die (MUD) inserts with a standard frame and removable inserts can be used. MUD molds, as they are called, can support the complexity that medical parts need; however, inserts made of metal can take a long time to machine.

3D-printed inserts take less time to produce, but the plastics they use may lack sufficient rigidity for accurate, functional parts. Unless a 3D printed insert has the proper surface finish, the MUD mold won’t produce low volumes of parts with high enough quality.

The Solution

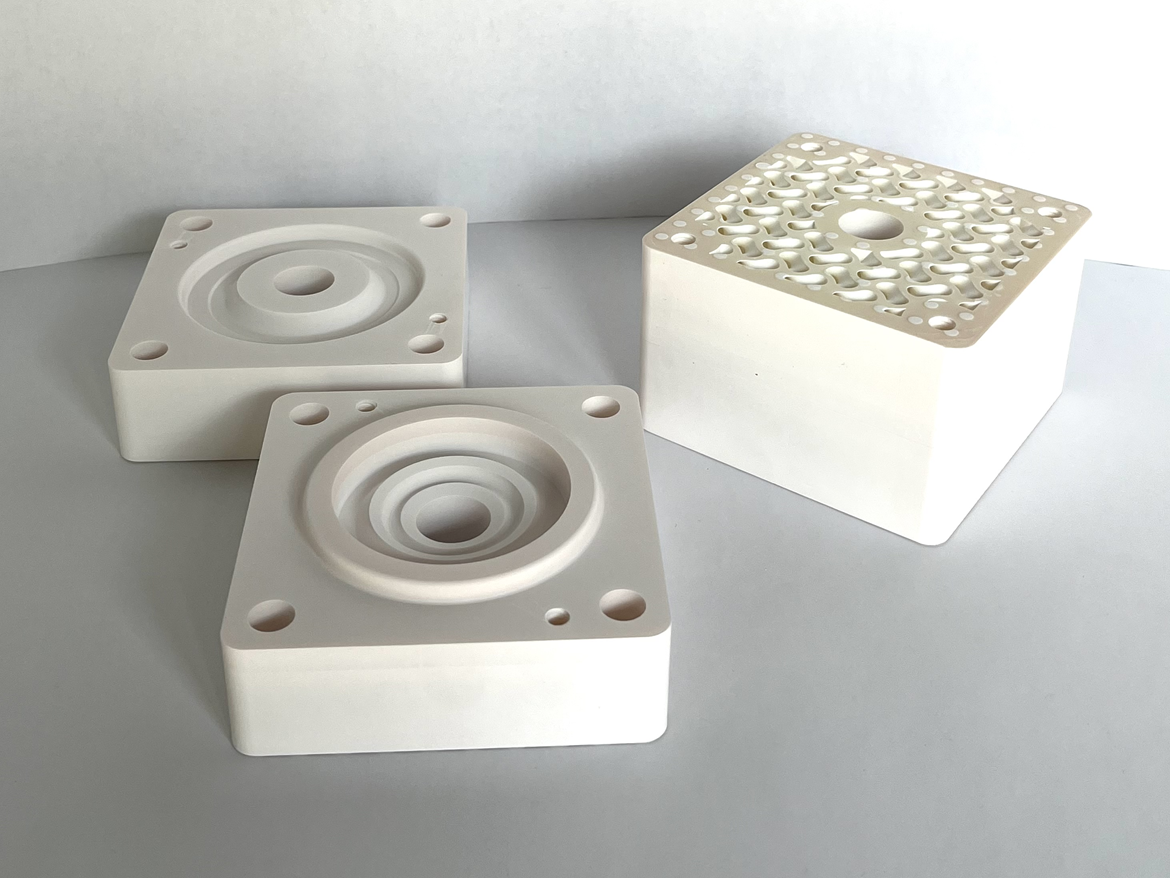

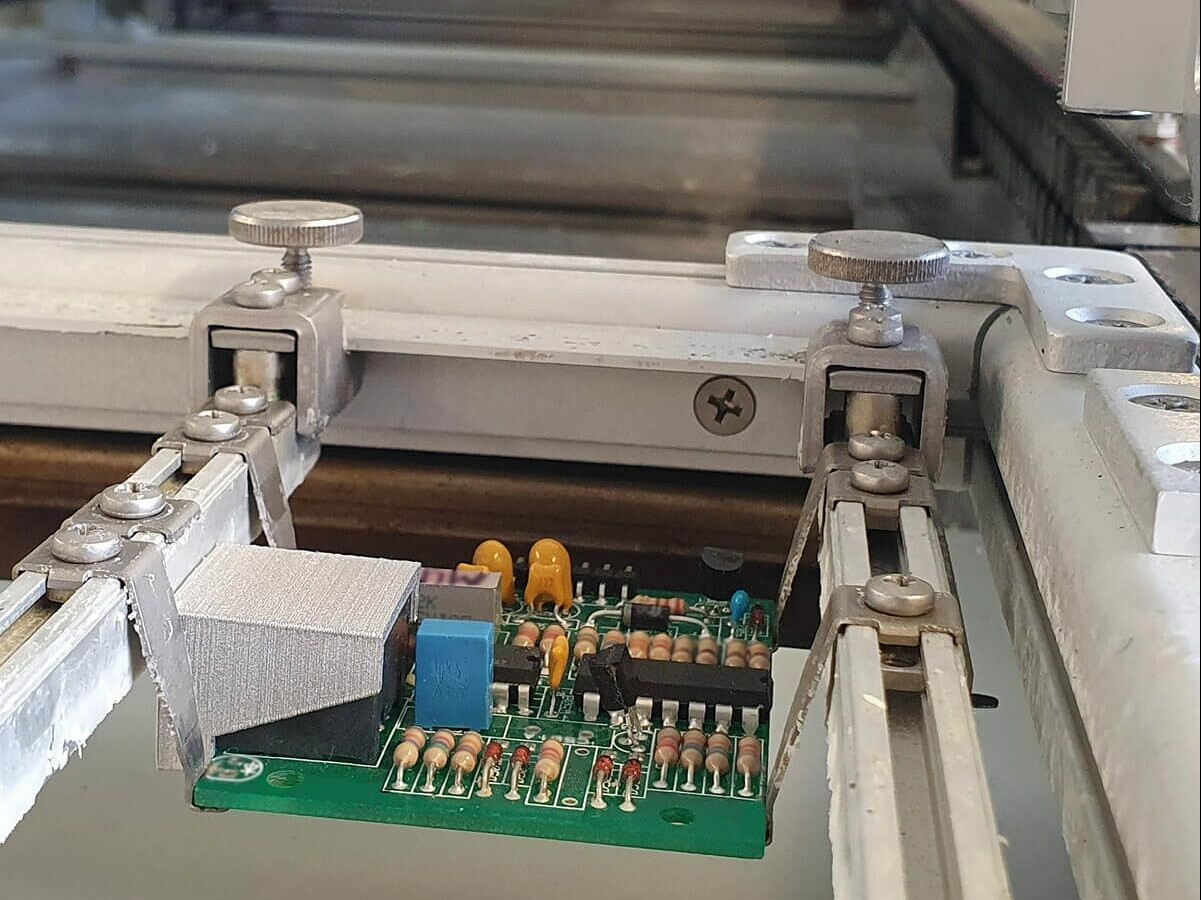

The solution to Becton Dickinson’s challenges came in two stages. The first began with the 45-minute design of a MUD mold insert. This core and cavity block was made of Ultracur3D® RG 3280 and produced with a Lumia X1 3D Printer. Ultra3d® RG 3289 is a ceramic filled resin with exceptionally high stiffness. The Lumia X1 combines high resolution with fast print speeds.

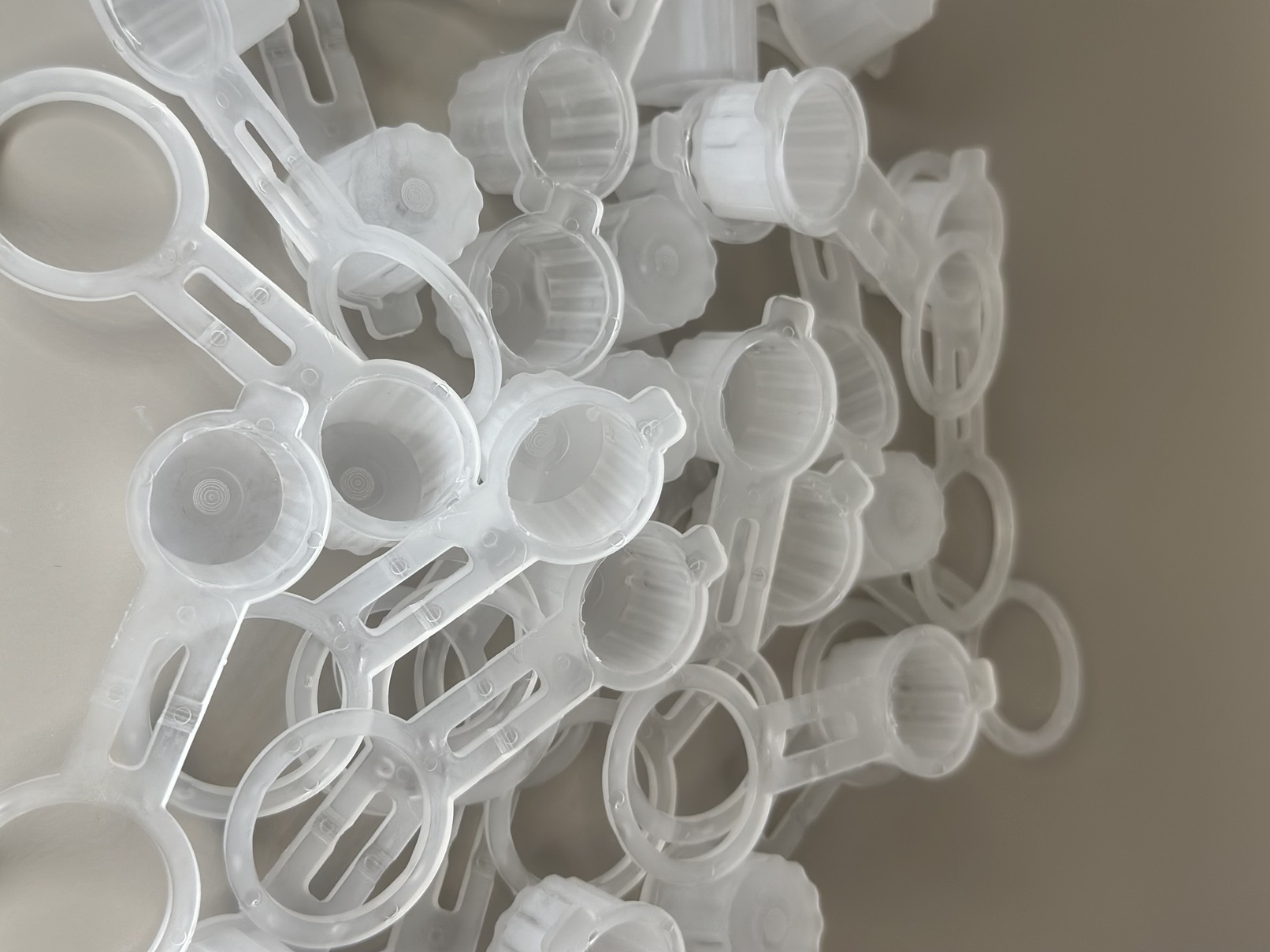

Printing took just 54 minutes to complete and was followed by post-processing, including cleaning and post-curing, that took about 60 minutes. Next, the 3D-printed insert was machined to fit the mold frame. This took about 120 minutes, and the entire mold was ready for the press in less than 5 hours. Some 30+ polypropylene parts were ejected by hand. They had a production-quality finish and exceeded expectations.

The second stage of the solution involved the automatic ejection of 100+ polypropylene parts and 100+ polycarbonate parts. Setting up the ejection pins lengthened the lead time, but over 300 functional parts were molded. When its partners urgently need low volumes, Becton Dickinson doesn’t have to wait long for tooling and gets quality parts.

The Result

The outcomes of these two-stage solution exceeded expectations. By using Forward AM’s Ultracur3D® RG 3280 with Axtra3D’s Lumia X1 printer, Becton Dickinson can rapidly produce MUD mold inserts for low volumes of high-quality parts. This versatile solution is also suitable for different types of injection molded plastics and supports both manual and automated parts ejection.

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!