3D-Printed Lattices Enable Padics’s Customized Kiteboard Bindings

How Padics is Revolutionizing Kite Bindings with 3D Printing for Mass Customized Products with Unique Damping Properties

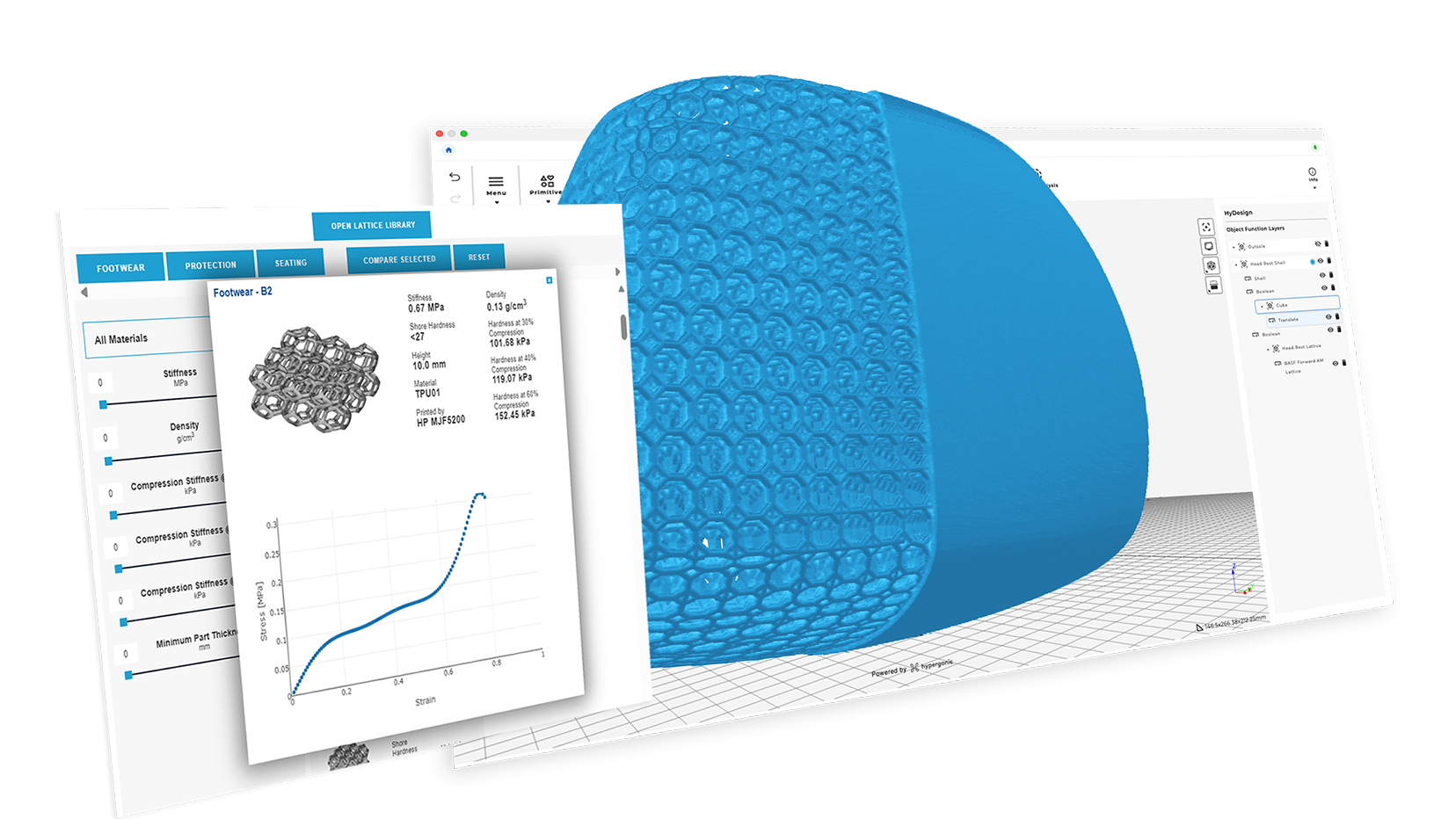

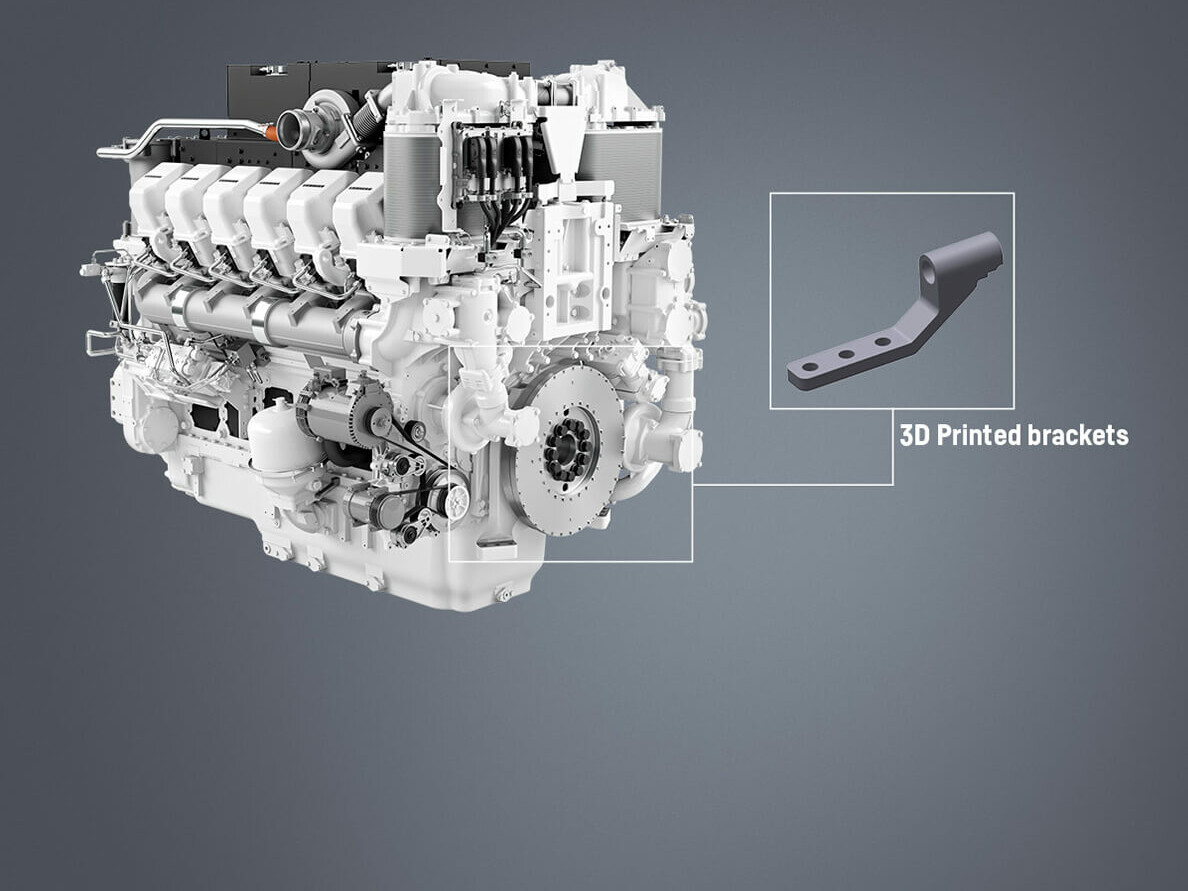

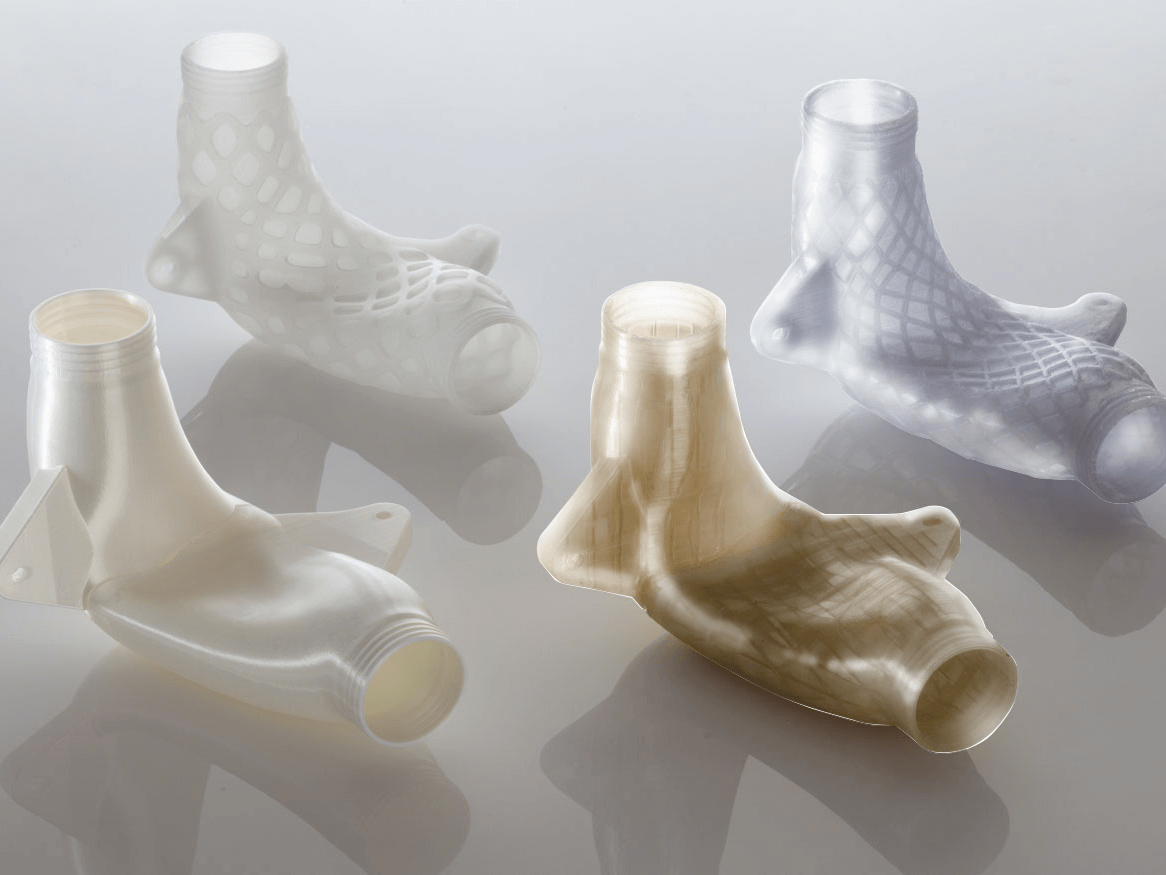

With Forward AM’s expertise in lattice structures, software and materials, Padics is making mass customization of kite bindings with unique cushioning a reality through 3D printing. The utilization of Hydesign, Hyperganic’s new cloud-based 3D design solution, supported the creation of kiteboard pads with the exact damping properties required by Padics, while Forward AM’s Ultrasint® TPU01 provided the perfect material for precise cushioning.

Project Breakdown

Industry & Application

Sports Equipment, Customized Kiteboard Bindings

Software Solution

Ultrasim® 3D Lattice Library with Hydesign, powered by Hyperganic

Material

Ultrasint® TPU01

Technologies Used:

MJF, Vapor Smoothing

Why Forward AM Solutions and Materials?

Leveraging Forward AM’s expertise in lattice structures, software integrations, project support, and material options, Padics is mass customizing their kiteboard bindings with unique dampening properties via 3D printing.

With the Ultrasim® 3D Lattice Library, choosing validated lattices with precise mechanical properties was an easy task. Hydesign, Hyperganic’s new cloud-based 3D design solution, enabled the creation of suitable lattice designs in a matter of minutes, while Forward AM’s Ultrasint® TPU01 provided the ideal material. This allowed Padics to 3D print pads with precise cushioning capabilities based on validated mechanical properties.

Padics, a German startup founded by Carlo, Ramona, and Fabian, is revolutionizing kiteboard bindings through innovative technologies like 3D printing. Utilizing advanced materials and cutting-edge design, Padics ensures exceptional comfort and functionality, setting new standards in the kiteboarding industry and making kitesurfing even more enjoyable.

The Challenge

The team at Padics was driven to create custom-made bindings began back in 2013 after an exhausting kite session caused spasms in the feet and knees of the company’s founders. Once they analyzed the bindings on the market, they quickly recognized the problem: there are only unisex models which are designed to fit a standard foot. As a result, important ergonomic features unique to an individual’s foot shape are not integrated in the pads.

The Solution

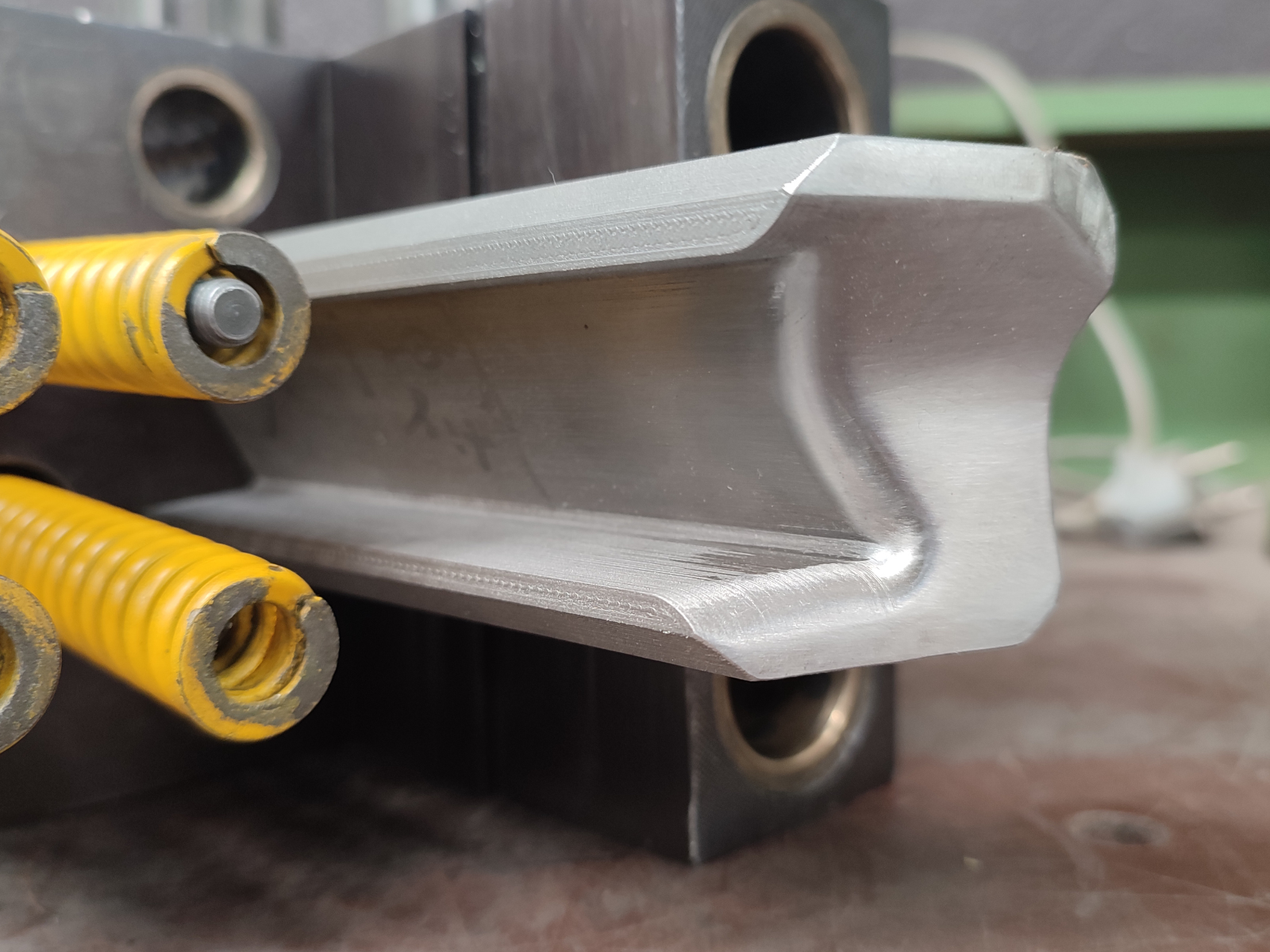

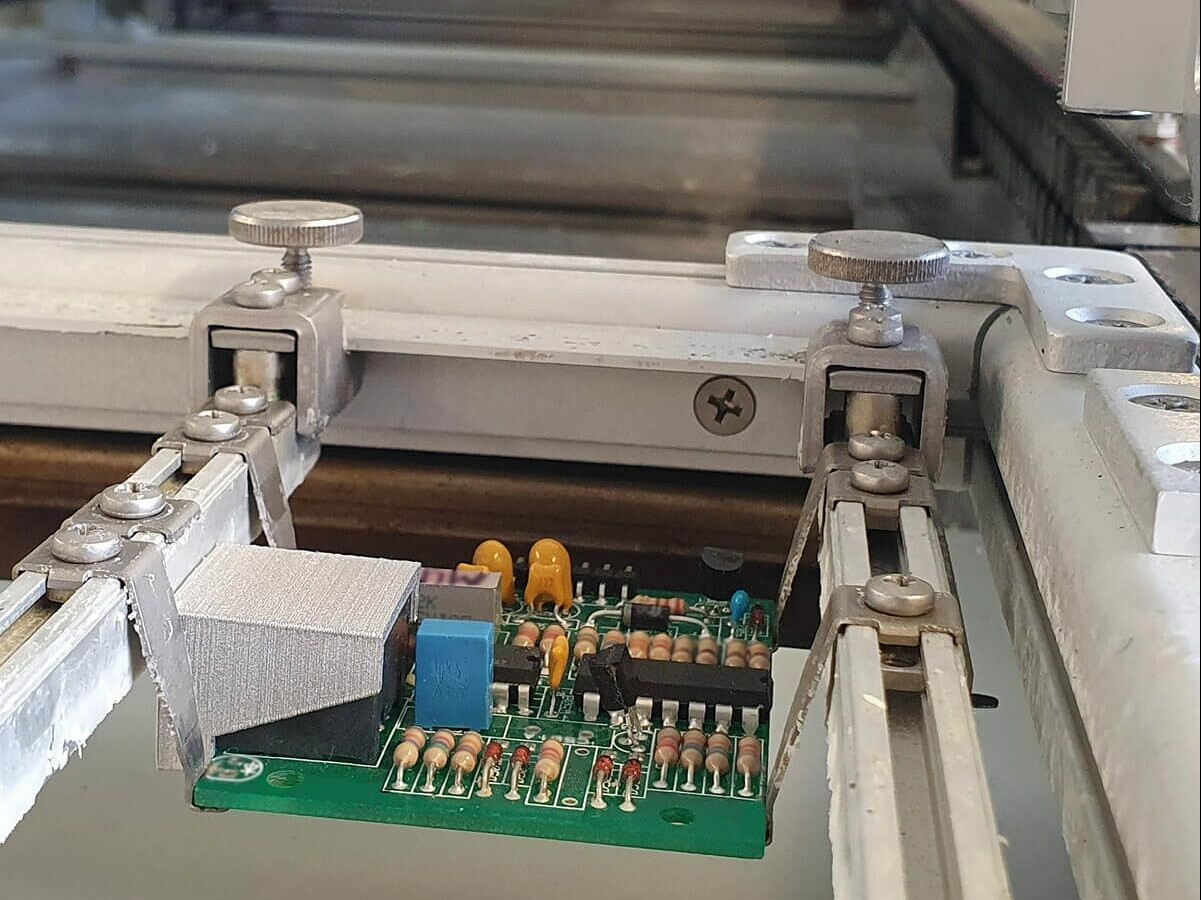

Padics partnered with Forward AM to design and produce a revolutionary, custom-made binding for kiteboards. The first prototype was featured at Formnext 2023 and showcased the broad potential of lattice structures manufactured through 3D printing. Made from Ultrasint® TPU01 on MJF technology, the initial tests conducted by Padics showed the vast potential of Additive Manufacturing to provide a unique riding experience with outstanding damping properties and improved grip.

Together we’ve pioneered a groundbreaking revolution in kitesurf pads by elevating the experience with the integration of TPU lattice structures. This innovation isn’t just about enhancing performance; it’s about personalized comfort and control. The utilization of AM technologies has allowed Padics to tailor the damping behavior to each rider’s foot shape. Whether female or male, these custom pads can accommodate a wide variety of unique foot structures and preferences to provide redefined grip, responsiveness, and unparalleled riding comfort. This customization ensures exceptional performance by adapting to the rider’s body weight and riding style delivering an unmatched experience on the water.

Lattices in 3D printing with validated mechanical performance are emerging as the pinnacle of damping design due to their unparalleled precision in damping capabilities. Consisting of repeating patterns of cells, beams, and nodes, these 3D-printed lattices enable entirely new designs that were previously considered unattainable. By meticulously fine-tuning lattice properties, designers can manipulate mechanical properties to achieve higher comfort, better rebound, better ventilation, and lower weight-all within a single material.

With millions of lattice options available, Forward AM’s Lattice Library provides a structured approach to understanding and selecting the most appropriate lattice for specific applications. By incorporating this knowledge into tools such as Ultrasim® 3D Lattice Test Pads, users can experience the wide range of properties that lattices can offer. By embedding this expertise, Hydesign, Hyperganic’s new cloud-based 3D design solution, combines algorithmic engineering with Forward AM’s validated lattice library, allowing users to instantly generate lattice parts with confidence. Years of experience, sophisticated material models, and rigorous quality control processes ensure the printability and depowderability of these validated lattices, making them indispensable in cushion design.

The Result

The Customization of the damping behavior to match the preferences and riding styles of an individual is essential. This approach by Padics ensures that riders can achieve their desired feel on the water by precisely tailoring the damping properties to their desires and needs. Whether an athlete is seeking a softer, more forgiving ride or a firmer, more responsive experience, 3D printing with lattices provides the necessary adjustments to enhance the kitesurfing experience.

By using Ultrasint® TPU01 and implementing lattice structures with the design, Padics was able to provide their customers with a customized footpad that could be manufactured in a serial production process. Forward AM brought a depth of expertise in latticing for damping structures that was crucial to the project and was only possible through 3D printing technologies.

The utilization of Hydesign, Hyperganic’s new cloud-based 3D design solution, supported the creation of kiteboard pads with the exact damping properties required by Padics. The finishing process used on the TPU01 material also made the pad surface repellent of the seawater in which it would be used ensuring longevity of the product.

“When it comes to achieving precise damping properties, nothing compares to 3D printing technology. That’s why we chose to work together with Forward AM & Hyperganic as experts in 3D printed materials and lattice applications. The Ultrasim® 3D Lattice Library made it super easy to select lattices with the exact damping we needed, and using Hydesign to create complex, custom lattice designs was a breeze!”

Carlo Neumann, Co-Founder at Padics

Share this page

Next Steps

Reference Links and Documents

- Hydesign, Hyperganic's new cloud-based 3D design solution

- Ultrasim® 3D Lattice Library

- Ultrasint® TPU01 Material Page

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!