Ultrasim® 3D NextMold

Faster Tooling for Fastest Prototyping

Discover Ultrasim® 3D NextMold – our solution for rapid tooling using 3D printed molds. Specializing in injection molding inserts, Ultrasim® 3D NextMold leverages the advanced photopolymer material Ultracur3D® RG 3280 to help you accelerate your product development cycles and streamline the production of prototypes and small series.

An Advanced Solution, Trusted by Experts

“Rapid tooling using BASF Forward AM’s materials saved us significantly, cutting costs from €2,500-€6,000 to under €500 per tool. Traditional milling took 4-6 weeks for delivery; in-house 3D printing got us results in just 9 hours. A game-changer for our production process!”

— Christopher König, Co-Founder and CTO of DREIGEIST

“The technology achieved the requirements for early prototype production and enabled us to check our product geometry and discover potential failures before we invested in an expensive mold. This meant we could eliminate production defects in the steel mold, therefore reducing the number of correction/optimization cycles.”

— Markus Kaaserer, Expert Techno Polymers, MD ELEKTRONIK

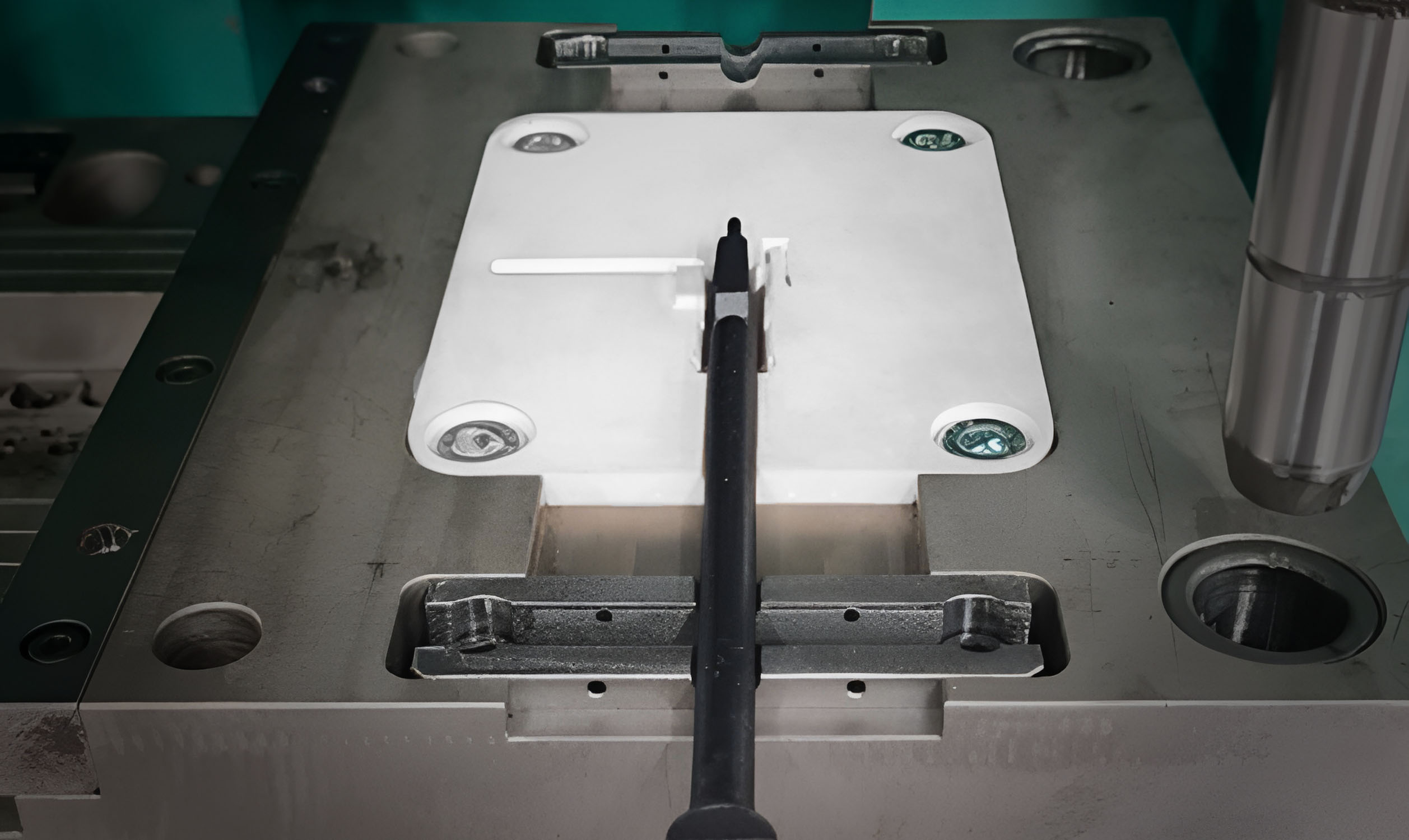

Ultrasim® 3D NextMold Prototyping at MD Elektronik

MD ELEKTRONIK uses our solution to quickly create 3D printed inserts for injection over-molded data cable prototypes. This reduces the need for metal molds, allowing new designs to be tested within a day instead of waiting up to 20 weeks for metal molds.

Accelerate your Innovation with Rapid Prototyping

Clear Time Advantage

Go Full Speed, Advancing Molding to the Next Level

- No delays from mold-suppliers

- Quick Design iterations for OEMs

- Quick sales cycles for contract manufacturers

Substantial Cost Advantage

Leverage AM to Reduce Short and Long-Term Costs

- Cheaper than CNC-milled steel molds

- No price volatility for external mold manufacturing

- Lower initial investment for machinery

Material Authenticity

Prototype in Final Materials for Accurate Testing

- Use Final Materials for your Prototypes

- Reduce Guesswork and Simulation Efforts

- Enhance Accuracy with Real-World Material Testing

Revolutionize your Prototyping Process

Ultrasim® 3D NextMold is designed to revolutionize your prototyping process, offering a faster, cost-effective, and reliable upgrade to traditional mold making. Whether you’re an OEM looking to accelerate your product development or a molder seeking to enhance your service offerings, our solution provides the tools and support you need to stay ahead in a competitive market.

Leverage AM-Accelerated Product Development

3-Day Leadtime | Ultrasim 3D NextMold Inserts

56-Day Leadtime | Conventional Steel Molds

Discover our Ultrasim® 3D NextMold Packages

Find the Right Solution Tailored to your Needs

- Engineering Services of AM Material Experts

- Software Solutions and Printing Services

- Fast-Track Ordering with Certified Service Bureaus

- DIY Resources

- Workshops and Ongoing Support

| Ready to Print | Ready to Use | Enterprise | |

|---|---|---|---|

For experienced AM users who want to profit from expert guidance in mold design, printing, and post-processing, plus free DIY resources. | For beginners in AM. Our end-to-end service delivers a ready-to-use 3D printed mold, including design, printing, and post-processing, with optional add-ons. | Tailored for your business. Get engineering services, software, a printer subscription with a trusted partner, and materials. Includes workshops and rapid support to maximize your technology's potential. |

|

| Design of 3D Printable Insert | Fast-Track |

||

| Printing Parameter Guidelines | |||

| Access to Learning Assets | |||

| 3-Hour Expert Consulting | |||

| 3D Printing Service | - | Service Bureau Network |

|

| Software Partner for AM Design | - | - | |

| Printer-on-Premise Solution | - | - | |

| Workshops & Support | - | - | |

| Mechanical Finishing | - | Add-on | Add-on |

| 3D Measurement Scan & Documentation | - | Add-on | Add-on |

| Mold Simulation | Add-on | Add-on | Add-on |

| Surface Texture Design | Add-on | Add-on | Add-on |

| Injection Molded Parts | Add-on | Add-on | Add-on / network |

| Extended Consulting | Add-on | Add-on | Add-on |

| AM Materials which can be used | Already validated Materials:

|

||

| What we need from you |

|

|

|

| Price | Starting at 400€ | Starting at 1.100€ | On Request |

Powerful Materials, Advanced Application

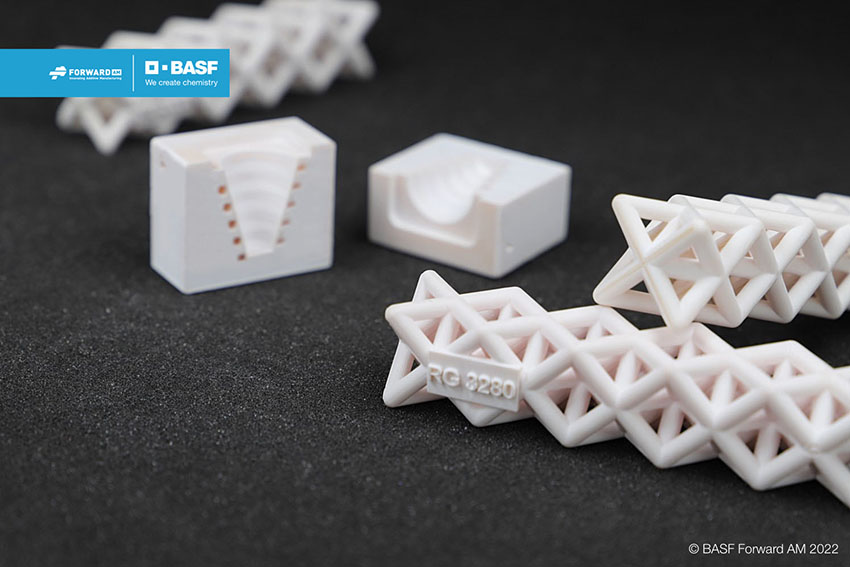

Ultracur3D® RG 3280

Ultracur3D® RG 3280 stands out among our resin lineup with exceptional properties. Despite its high particle loading, it maintains low viscosity and minimal particle settling, ensuring easy handling and printing. With high stiffness and temperature resistance, it's ideal for tooling, molding, and wind tunnel testing. Plus, its white, ceramic-like appearance adds to its versatility.

Benefits at a Glance

- Superior stiffness

- Superior temperature performance

- Very fast and easy to print

- High suspension stability

Material Properties

- Young’s modulus: 10,000 MPa

- Tensile strength: 76 MPa

- Heat deflection temperature: >280 °C

- Viscosity, 30 °C: 230 mPas

Stay ahead in a competitive market

Accelerate your prototyping process with Ultrasim® 3D NextMold.

Request your free consultation today!

3D Printed Molds: Discover More Use Cases

Additive Manufacturing Delivers Durable Mold Parts for Quick Tool Production

Innovative material and enhanced design provides superior performance and exceptional durability for industrial filtration screens

Innovative Rapid Tooling: Bridging the Gap between Traditional Tooling and the Future with 3D-Printed Injection Molds

With Additive Manufacturing, it can be challenging to produce parts with professional-grade surface finishes, making post-processing an essential…

3D Printed Injection Molding Inserts for Prototypes by MD ELEKTRONIK

MD Elektronik uses BASF Forward AM materials to speed up the creation of 3D printed inserts and create injection overmolded data cables