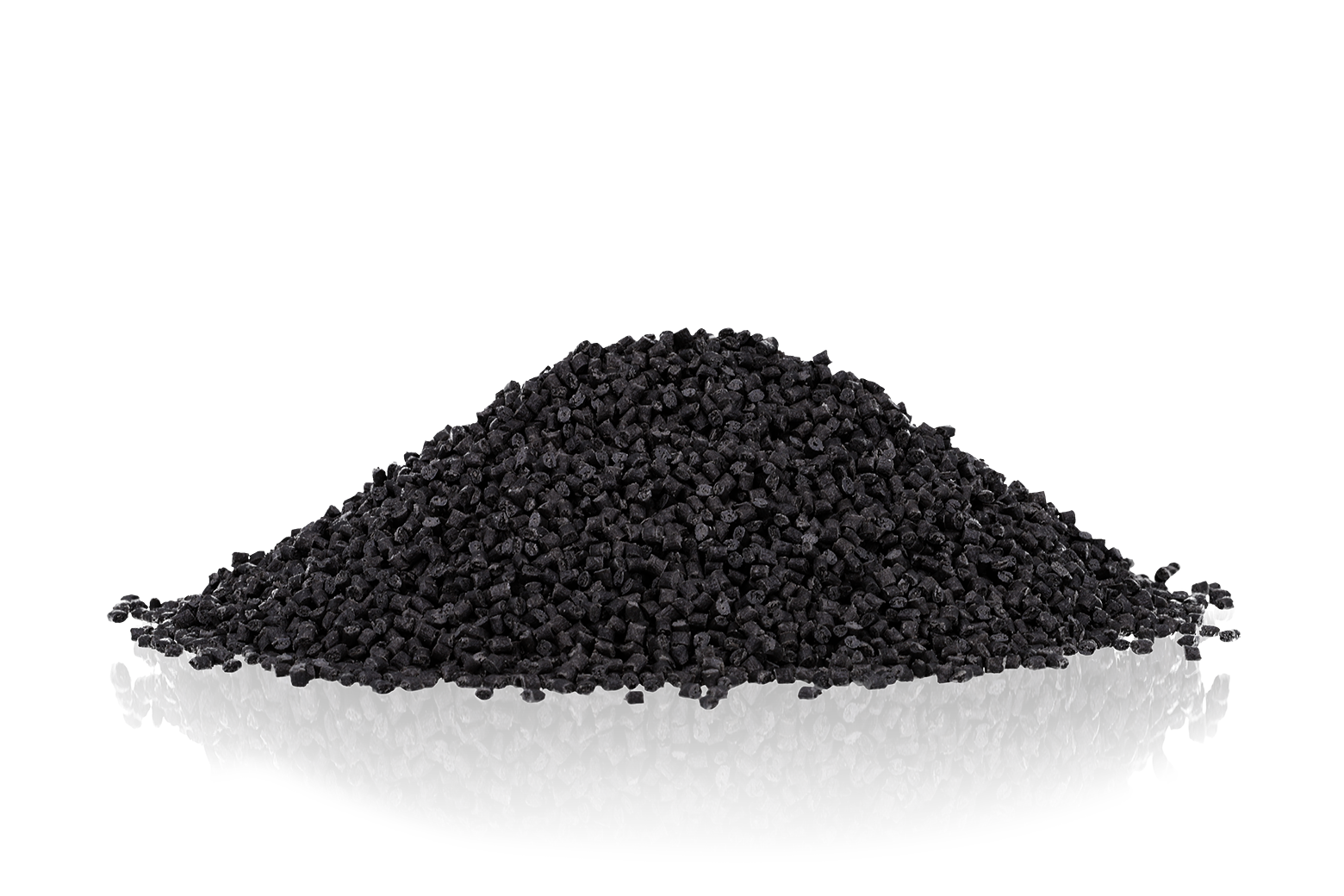

Ultrafuse® Pellets PP GF30

Premium Glass Fiber Reinforced Micro-Pellets:Unmatched Extrusion and Surface Quality in Demanding Applications

Introducing Ultrafuse® PP GF30: These high-performance polypropylene (PP) micro pellets are reinforced with 30% glass fiber, ensuring high stiffness, high heat resistance, and enhanced UV stabilization. Designed for demanding applications such as tools, molds, and holders, as well as environments sensitive to moisture or chemicals, they deliver exceptional performance.

Material Details

-

- Product Leaflet

- Technical Data Sheet: EN

- Material Safety Data Sheets

True Polypropylene Made Easy

Ultrafuse® PP GF30 pellets work smoothly with virtually all extruder systems, thanks to their micro pellet dimensions that allow easy and consistent feeding. Ideal for both desktop and industrial 3D printing, these easy-to-print pellets guarantee outstanding surface quality while preserving the inherent properties of homopolymer polypropylene.

With consistent extrusion flow and a high degree of filling, Ultrafuse® Pellets PP GF30 achieves detailed and homogeneous surface qualities without compromising speed or warpage, making it perfect for both beginners and professionals in prototyping or series production.

Benefits at a Glance

- Excellent chemical resistance: Preserving the Inherent Properties of Homopolymer PP

- High Stiffness: Reinforced with 30% Glass Fiber

- Low density: PP has naturally a low density

- Low moisture uptake: The wax-like base structure of PP polymers has natural water-repellency

- Excellent for demanding applications: High heat resistance, protection from moisture absorption

- Improved UV resistance: UV stabilizers ensure long service life of parts, even outdoors

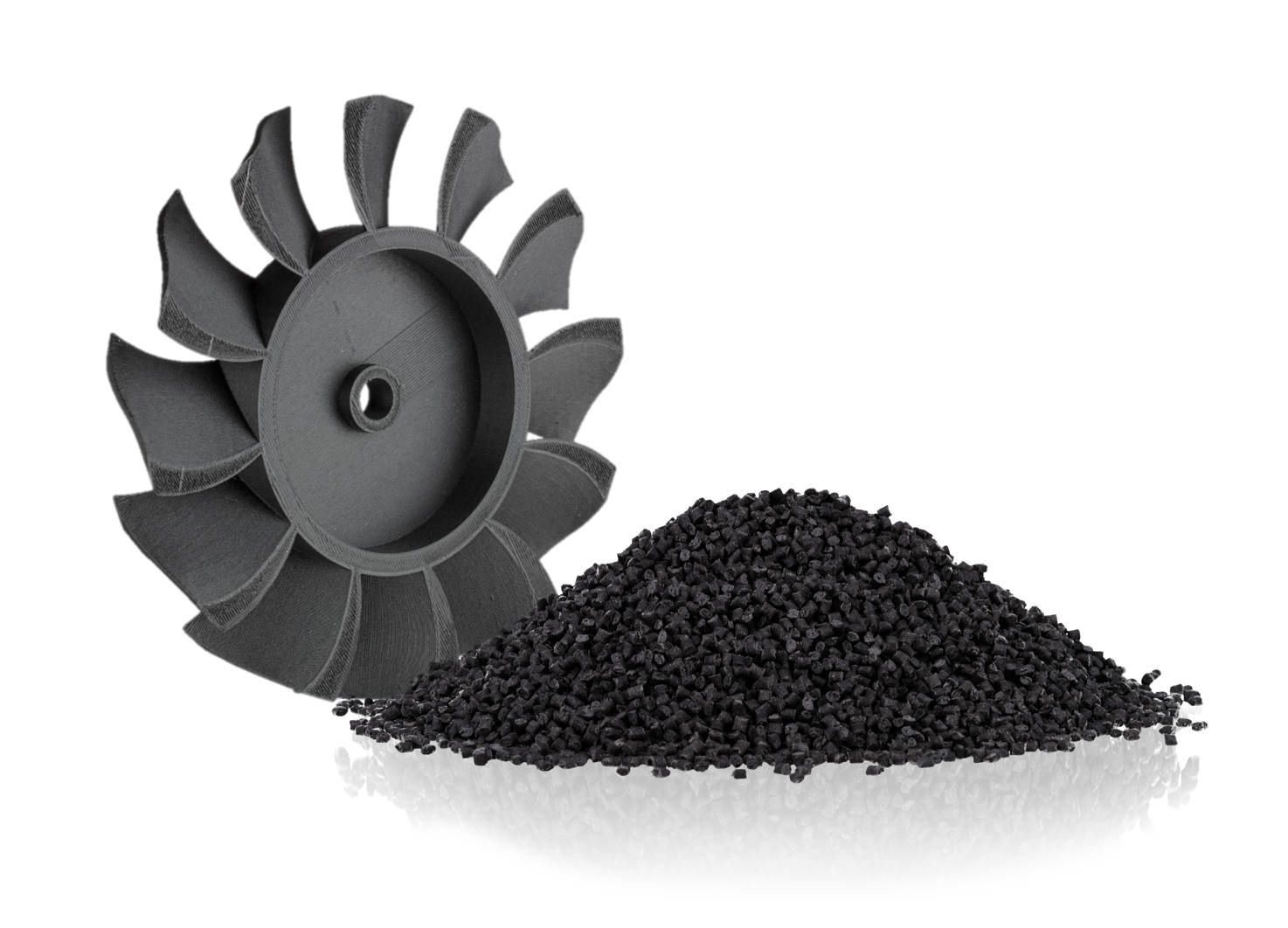

Example Applications

- Jigs & fixtures

- Tooling

- Manufacturing aidsy

- Any kind of molds (especially if chemicals are involved)

- Housing and functional prototyping

Material Properties*

- Tensile Strength (MPa): 41,7 (XY); 15,9 (ZX)

- Flexural Modulus (MPa): 3507 (XY); 4026 (XZ); 1671 (ZX)

- Elongation at Break: 4,4 % (XY); 0,8 % (ZX)

- Impact Strength Charpy unnotched (kJ/m2): 23,1 (XY); 25,8 (XZ); 2,5 (ZX)

- Impact Strength Izod unnotched (kJ/m2): 20,5 (XY) , 2,4 (XZ); 2,6 (ZX)

- HDT at 0.45 MPa: 127 oC

Recommended Print Settings*

| Recommended Extrusion Parameters | |

|---|---|

| Zone 1 Temperature | 210 ± 10 °C |

| Zone 2 Temperature | 225 ± 10 °C |

| Zone 3 Temperature | 235 ± 10 °C |

| Nozzle Temperature | 250 ± 10 °C |

| Extrudate Temperature | 80 ± 10 °C |

| Drying Recommendations | |

|---|---|

| Temperature | Min. 55 °C; Max. 70 °C (prevent sticking) |

| Time | 4 - 16 h |

| Condition | <1000 ppm |

* The product data is provided in good faith and represents typical properties based on our current knowledge of the Ultrafuse® PP GF30 filament and experience; these data are not to be construed as specification limits or minimum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application.

Use Case of Ultrafuse® PP GF30

Elite Biathletes Reach Peak Performance with Athletics 3D and Forward AM

In top-level professional sports, an athlete’s equipment is often the decisive factor between winning or just being one of the packs. This is especially true for the biathlon, an increasingly popular sport that’s also an Olympic discipline.

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® Materials

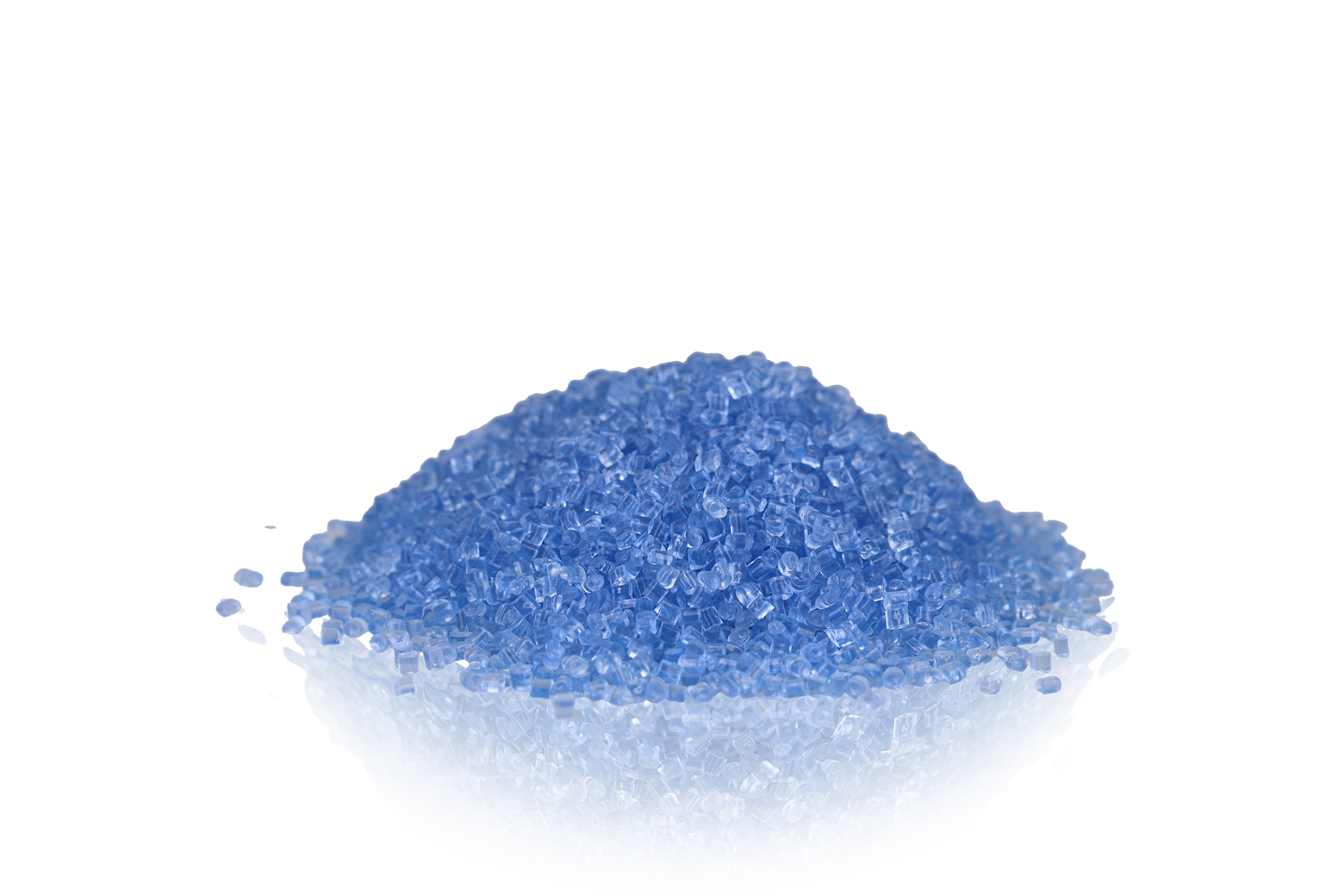

Ultrafuse® Pellets rPETG

Ultrafuse® Pellets rPETG: Sustainable, Cost and Time-Saving Large Scale 3D Printing

Benefits at a Glance

- Recycled, Traceable Industrial Waste Source

- Superior Optical Appearance

- Easy to print

- Low warping End Results

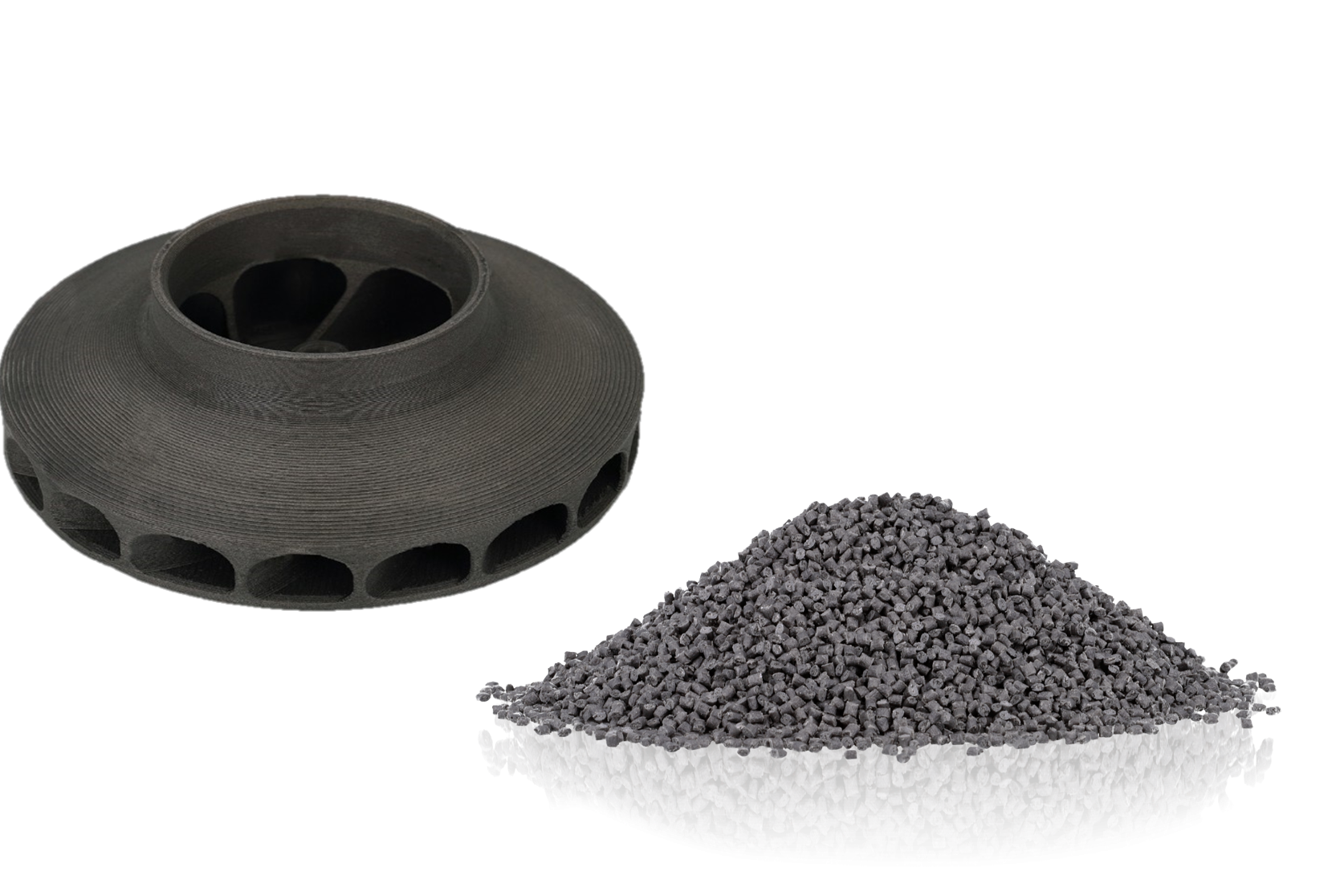

Ultrafuse® Pellets PC GF30

Ultrafuse® Pellets PC GF30: Flame Retardant Micro Pellets, Glass Fiber Reinforced

Benefits at a Glance

- Flame Retardant

- High Stiffness, Glass Fiber Reinforced

- Temperature Stability and UV Resistance