Biocompatibility for Ultrafuse® Filaments

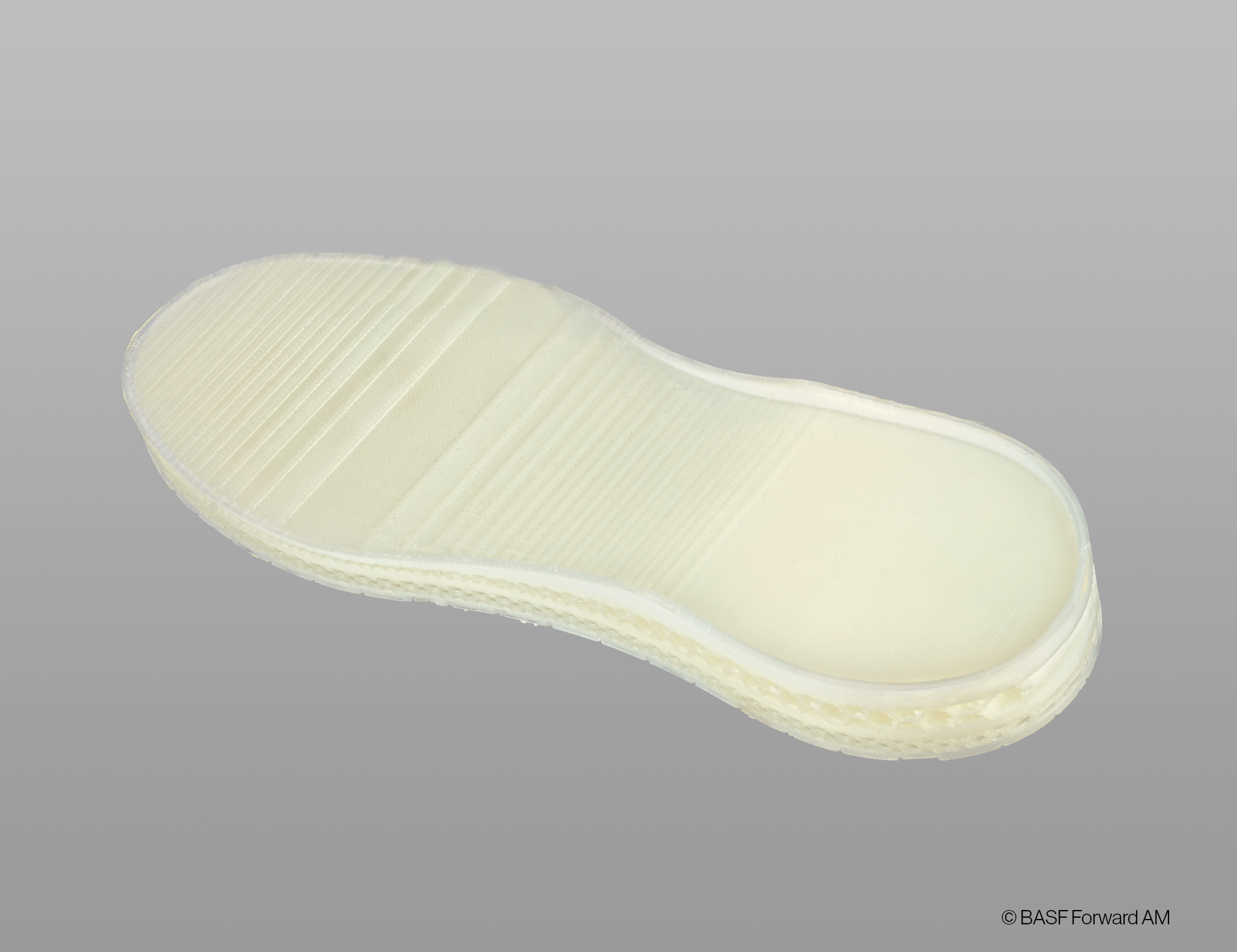

No two bodies are the same, especially in the medical industry. A perfectly tailored solution is often necessary to achieve the best outcome for the patient. Additive Manufacturing offers the possibility to individualize the patient’s medical solutions, whether orthoses, prostheses, or other devices. However, one of the most essential aspects is that the printed parts are safe for the patient to use. In Industries focusing on wearables such as footwear with e.g. insoles the material for the 3D printed part has to be safe as well

Six Ultrafuse® filaments are now tested according to ISO standards and safe for skin contact.

Filaments Tested according to ISO Standards

The biocompatibility of the products is very important to ensure the patient’s safety when using the printed devise. Therefore, we tested* our filaments:

- Cytotoxicity XTT neutral red ISO 10993-5

- Skin irritation Ultrafuse ISO10993-10

- Skin sensitization LLNA KretinoSens ISO10993-10

The test filaments are mostly part of our flexible filament line, but we also tested a standard filament and an engineering filament. Which filament suits your application? Let’s take a look:

Ultrafuse® TPU 64D: This filament is strong yet flexible and easy to print. It can be used for functional flexible parts.

Ultrafuse® TPU 95A: Like the filament before, TPU 95A is excellent for functional flexible parts, impresses with outstanding abrasion resistance, and is a well-balanced combination of flexibility and durability.

Ultrafuse® TPU 85A: The key features of this filament are its good flexibility at low temperatures, good wear performance, and good damping behavior. It is an excellent fit for footwear projects.

Ultrafuse® TPS 90A: Parts printed with TPS 90A have a soft touch and are non-slip. Applications can, for example, be handles of appliances.

Ultrafuse® PP: PP is tough and strong, lightweight, and chemical resistant. Ideal Polypropylene based material for 3D-printing applications which have to endure high stress or strain

Ultrafuse® PLA Pro1: PLA PRO1 is an extremely versatile, tough biobased PLA filament for professionals and developed as a high-speed engineering thermoplastic.

Real-Life Applications with Ultrafuse®

There are already real-life applications like our Use Case with Victoria Hand Project and Spentys or our White Paper about Additive Manufacturing in the Healthcare Industry. Both companies are using Ultrafuse® filaments to face their respective challenges and create a medical solution for their customers that will make their life easier. Additive Manufacturing, in combination with Ultrafuse® filaments, can be used in many more real-life applications.

“Do you want to tackle a wearable challenge? We are happy to support you and create a better tomorrow for your customers and patients.”

*The biocompatibility tests were recorded on test specimen of the above referenced product to show compatibility of the material in general. The biocompatibility tests listed are not part of any continuous production protocol. The test assessments reflect only the test specimen and have to be retested on the final product. It remains the responsibility of the device manufacturers and/ or end-users to determine the suitability of all printed parts for their respective application. F o r n o t i c e: We give no warranties, expressed or implied, concerning the suitability of abovementioned product for use in any medical device and pharmaceutical applications. All information contained in this document is given in good faith and is based on sources believed to be reliable and accurate at the date of publication of this document. It is the responsibility of those to whom we supply our products to ensure that any proprietary rights and existing laws and legislation are observed.

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.