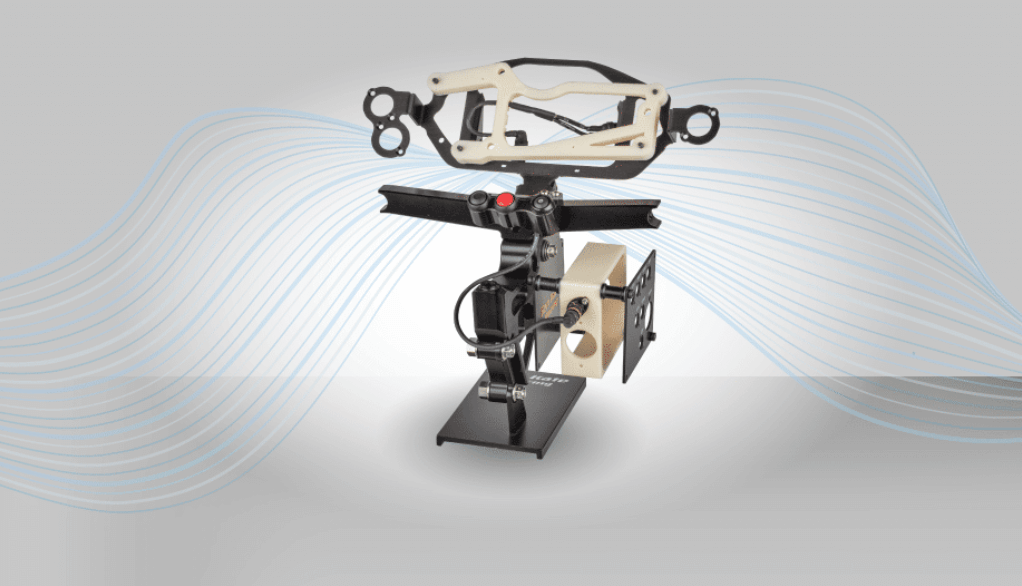

Dashboard Spacer | Junction Box Housing

Printing the Power to Perform – with AM

Staying Ahead of the Curve is Decisive: Motorsports pros take this statement literally. To gain that crucial competitive edge, pro racers constantly strive to optimize their bikes’ parts to shave a hundredth of a second off lap times.

Project Breakdown

Industry

Automotive

Project

Dashboard Spacer | Junction Box Housing

Why Forward AM?

End-to-end solution from design to production

Forward AM materials used

Ultrafuse® ABS Fusion+

The result

Shorter production and development cycles plus increased design flexibility

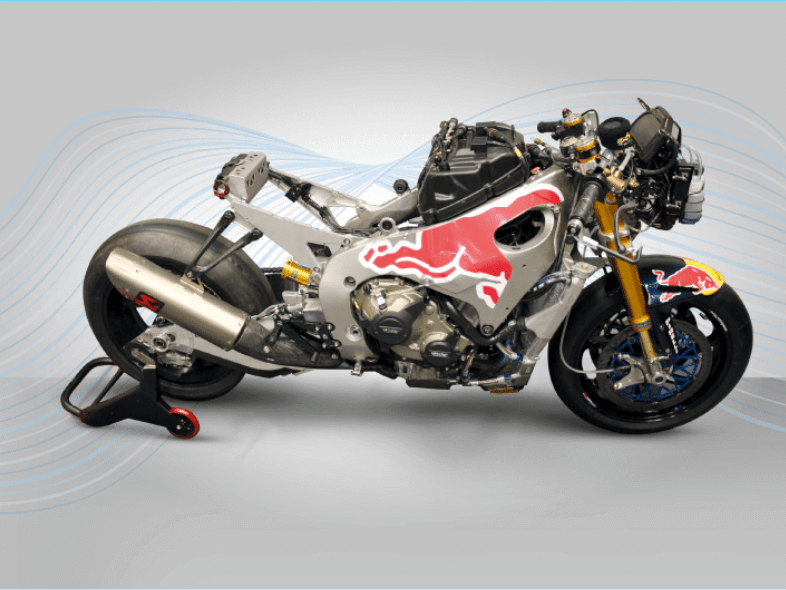

Pushing the Boundaries of AM in Motorsports with Ten Kate Racing

Searching for a way to produce superbike parts faster and more flexibly, Dutch superbike team Ten Kate Racing chose to partner with Forward AM. The goal was to find a material which would meet the extreme demands of top-flight motorcycle racing whilst being super-simple to use on a desktop 3D printer.

Until recently, Ten Kate had used traditional milling to manufacture their parts – a very time-consuming and cost-intensive machining process. A constant feature in the Superbike World Championship since 1995, the racing team faces challenges such as rapid and brutal changes in temperature, mechanical loads and heavy vibrations. This means racing parts have to be redesigned and adjusted very frequently, then produced very quickly. Using Additive Manufacturing enables the Ten Kate team to manufacture reliable parts that excel under the toughest racetrack conditions.

“Outstanding material performance is vital for us. 3D printed parts on our race bikes have to be absolutely reliable.”

Bastiaan Huisjes, Development Manager, R&D at Ten Kate Racing

Easy to Use, Hard to Beat – Ultrafuse® ABS Fusion+

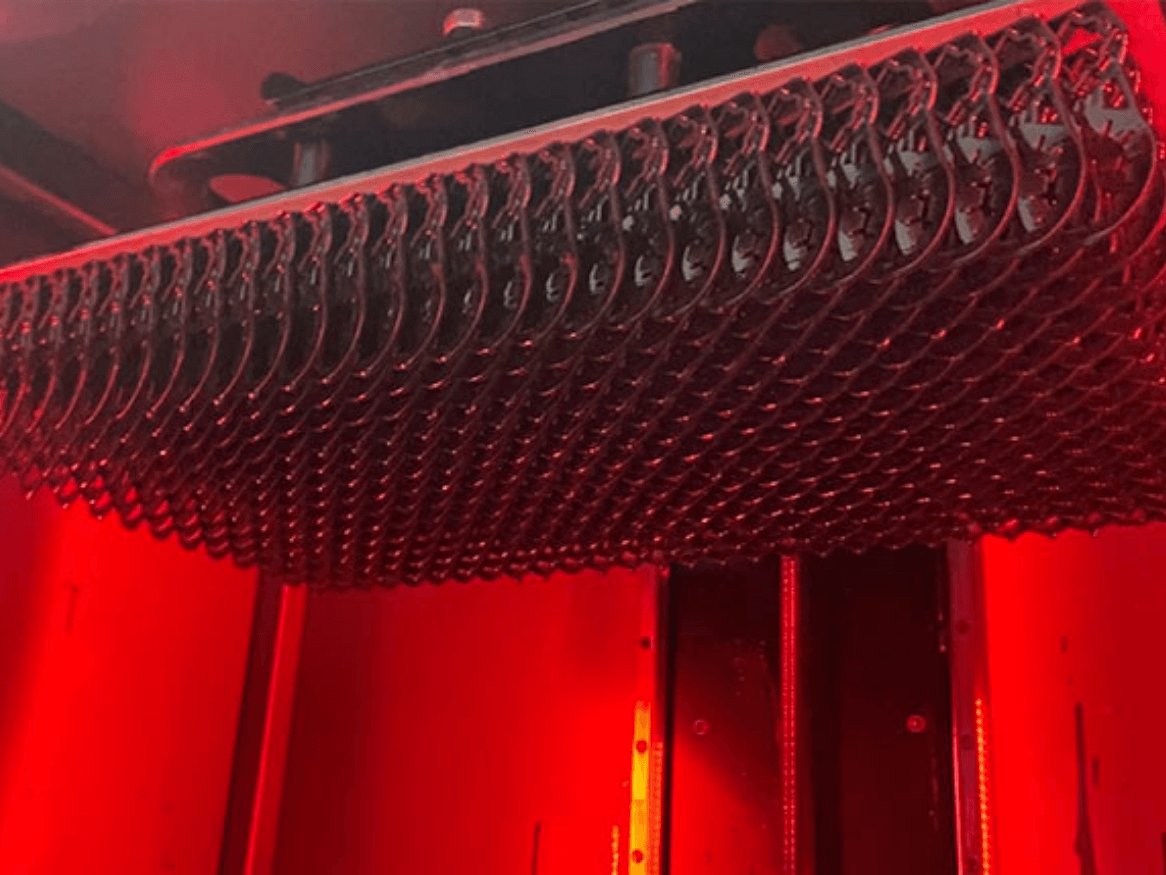

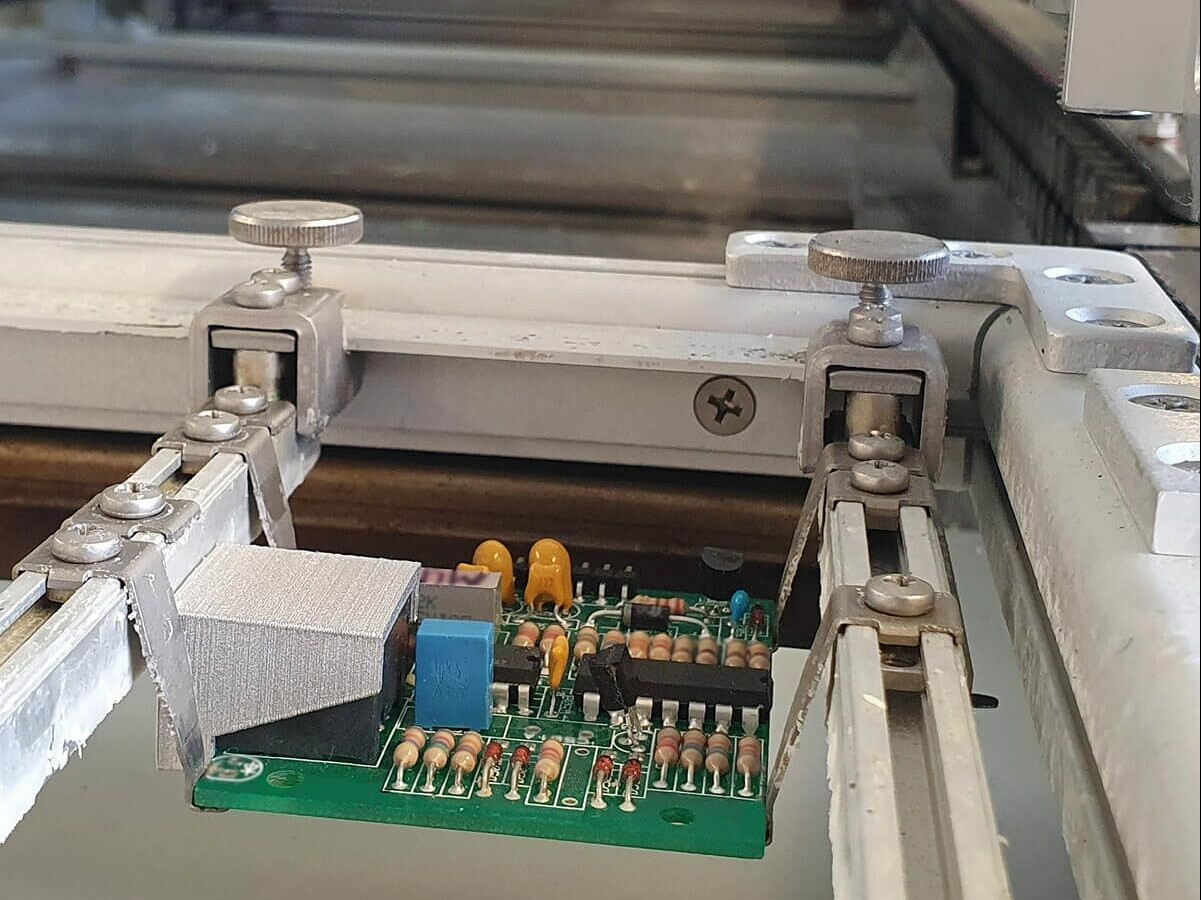

The perfect match for the challenge was Forward AM’s Ultrafuse® ABS Fusion+. This new advanced filament is outstandingly easy to use, enabling a highly efficient printing process that gives the 3D operator maximum time to exploit the full production potential without the need for continual readjustment.

Together with Ten Kate Racing, Forward AM started by 3D printing the bikes’ dashboard spacer and junction box housing. Previously, designing and milling these parts took at least three weeks: By going additive with Forward AM, Ten Kate Racing successfully shortened the lead time to just seven days. “With Ultrafuse® ABS Fusion+ we’re 3D printing more and more racing components – even complex shapes like retainer brackets”, Bastian confirms.

Benefits of Ultrafuse® ABS Fusion+ at a Glance

- Easy to print

- Direct printing on heated glass or print bed surfaces

- High heat resistance

- Adheres to water-soluble support

Result: High Speed in the Workshop – Top Speed on the Track

By harnessing the phenomenal potential of Additive Manufacturing, Ten Kate Racing was able to speed up the development and production cycle of their bike parts, giving the team an undeniable advantage on race day. Ultrafuse® ABS Fusion+ gives Ten Kate the component printing simplicity, reliability, and design flexibility to keep the team a development step ahead of the competition.

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!