Rhubarb by Atelier DARN:

Championing Sustainability with Ultrafuse®️ rPET at FAV 2024

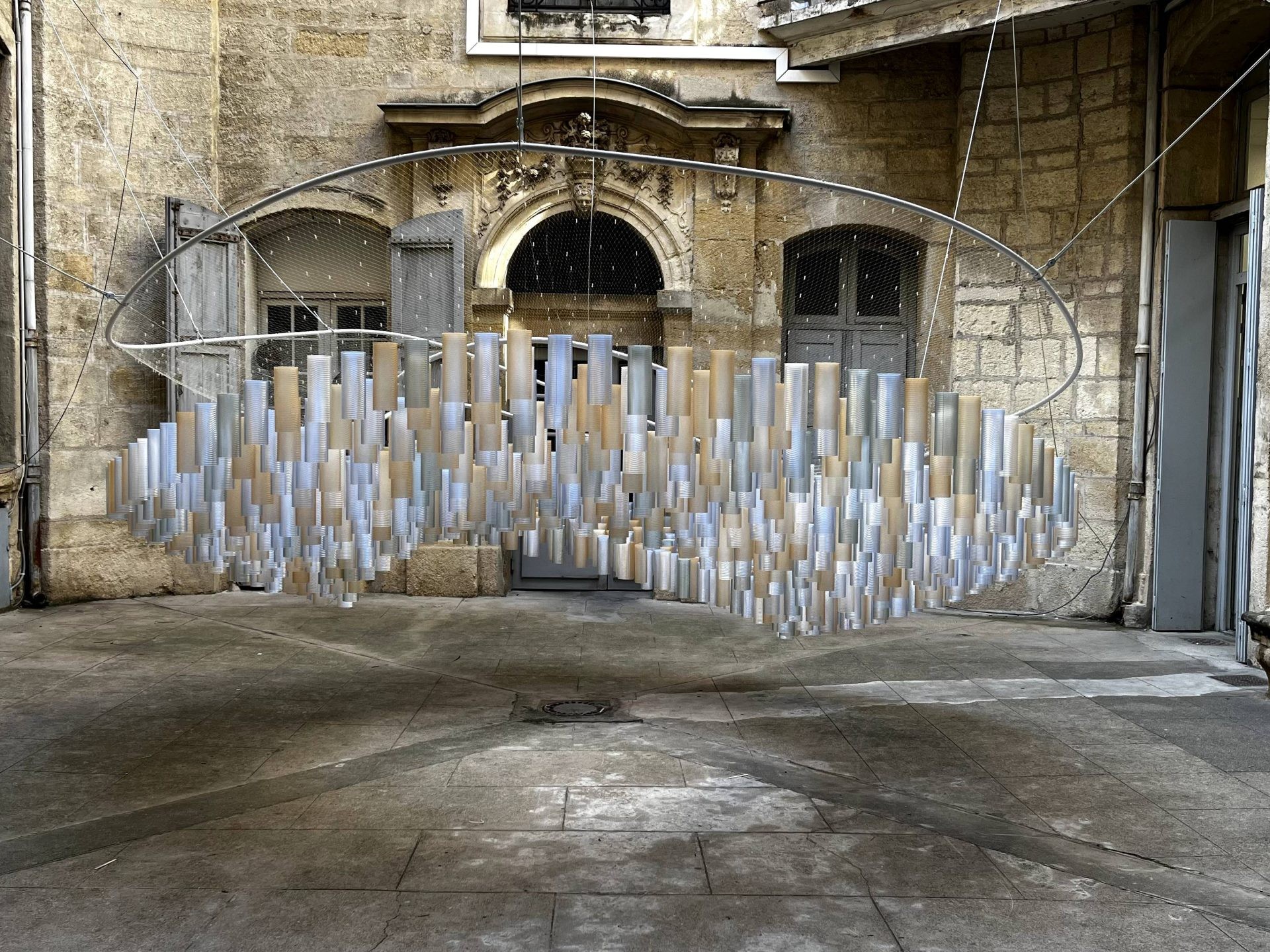

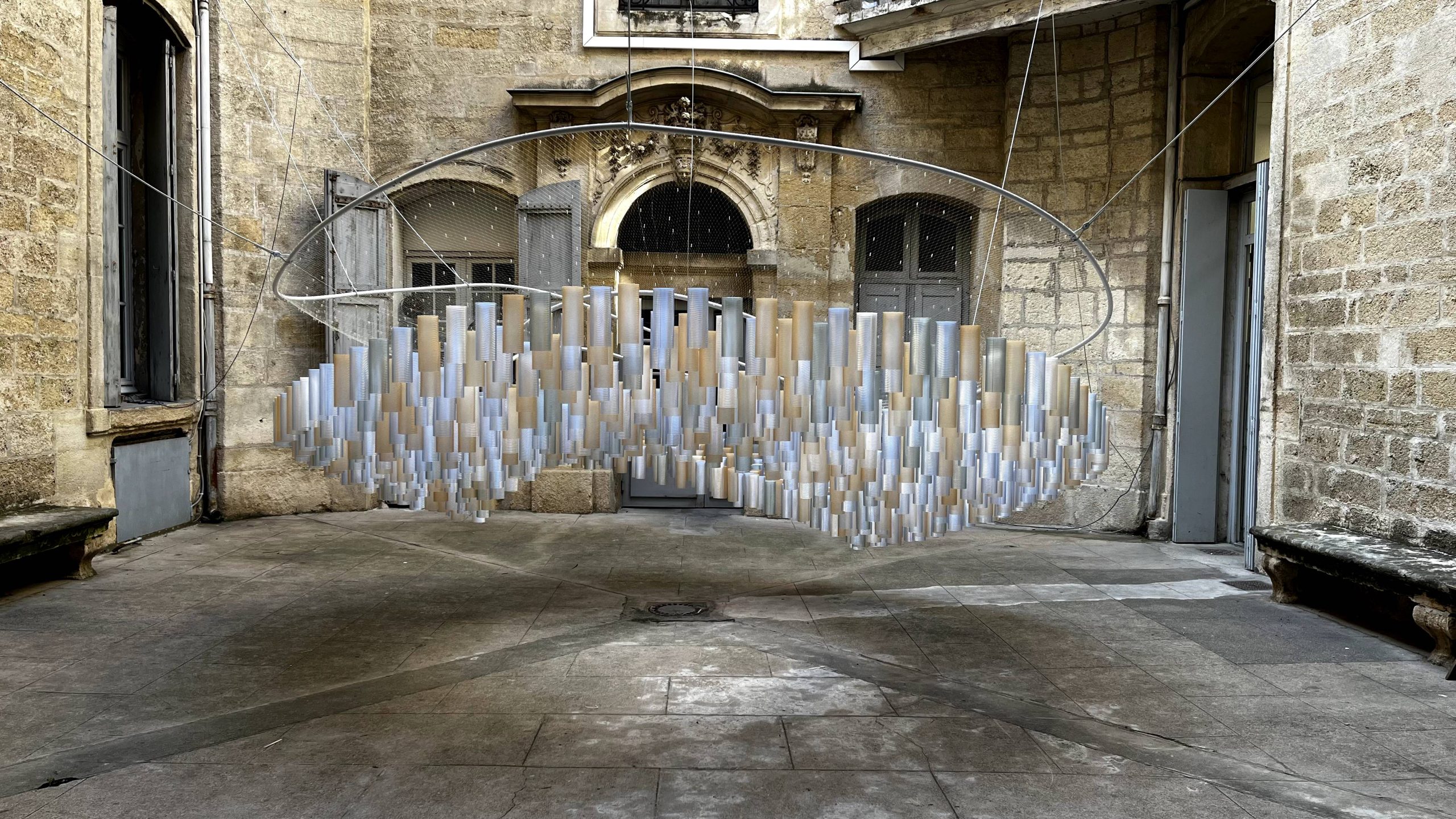

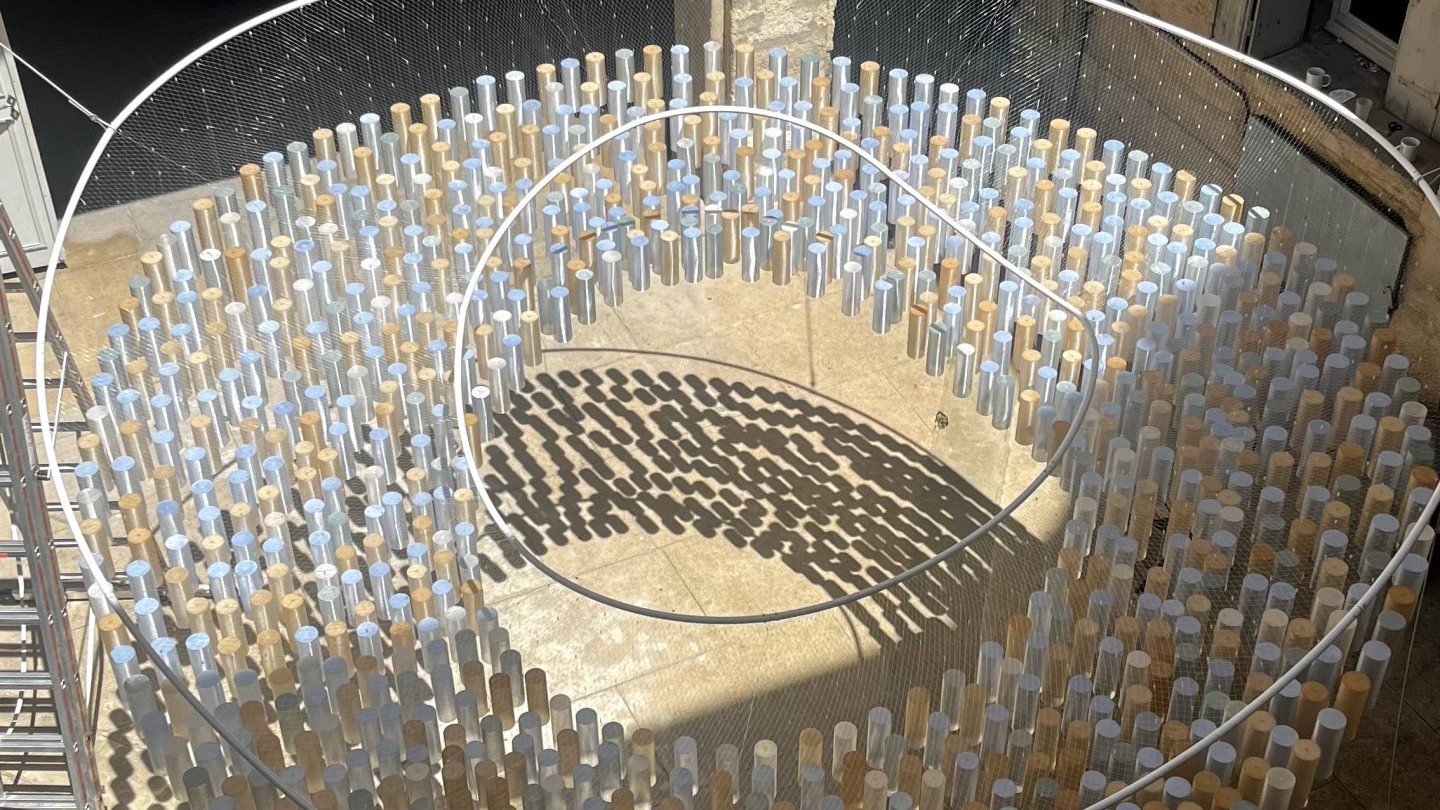

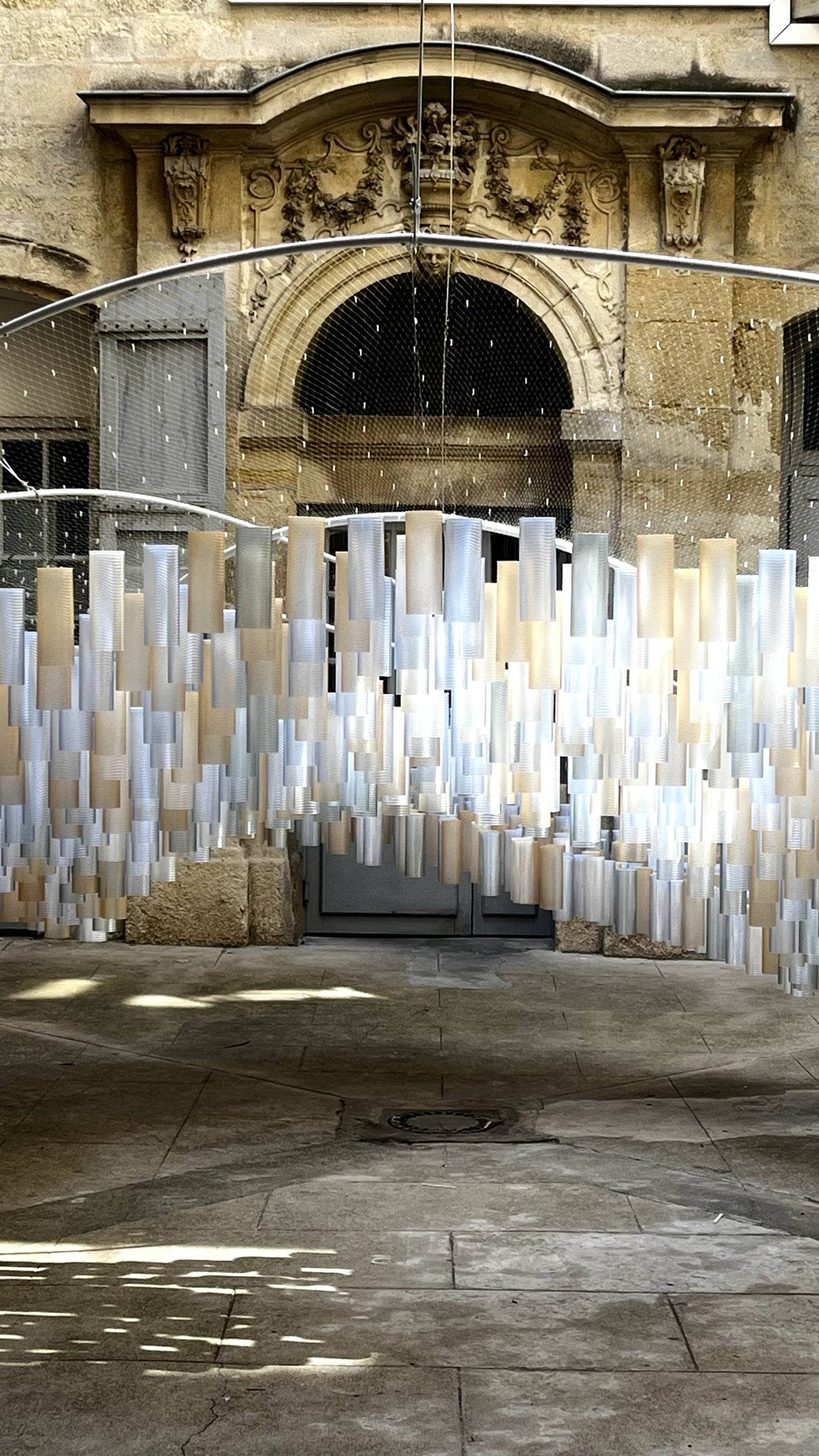

Atelier DARN’s installation, RHUBARB, triumphed at the 2024 Festival des Architectures Vives (FAV) by winning the public prize. This innovative piece, featuring 1,000 3D-printed elements made from Forward AM’s Ultrafuse®️ rPET filament, brilliantly combines art, architecture, and sustainability. Ultrafuse®️ rPET, crafted from recycled PET post-industrial waste, demonstrates that eco-friendly materials can achieve high performance and aesthetic appeal.

Project Breakdown

Industry & Application

Architecture, Art Installations

Material

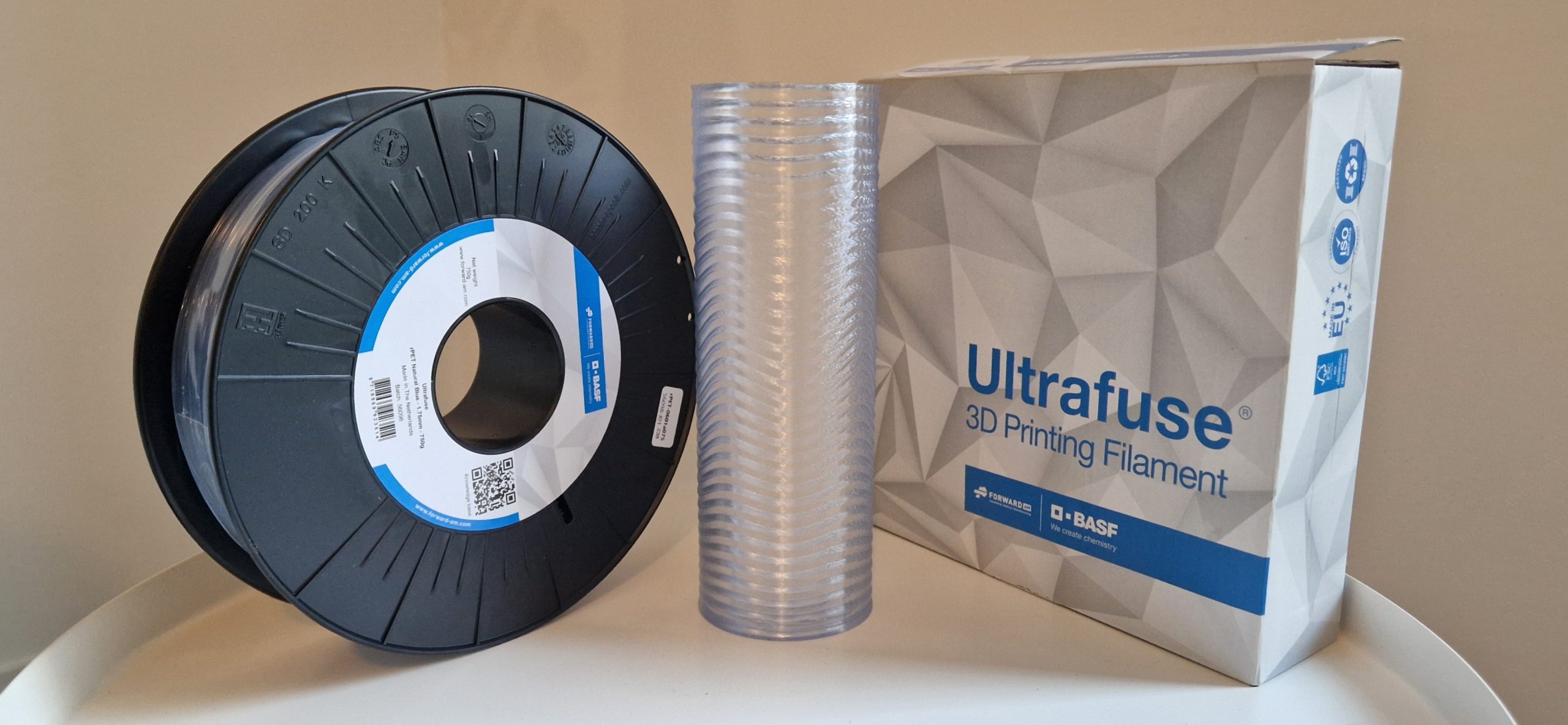

Ultrasfuse® rPET: Ultrafuse® rPET is a high-performance 3D printing filament made from recycled PET post-industrial waste. It boasts excellent mechanical properties and a transparent blue hue, comparable to virgin PET filaments. Meeting European food safety standards, it offers a sustainable solution to reduce plastic waste in manufacturing.

Why Forward AM Materials?

Forward AM’s Ultrafuse®️ rPET filament, made from recycled PET post-industrial waste, offers an eco-friendly alternative to traditional filaments without sacrificing quality. Its success in projects like Atelier DARN’s RHUBARB installation at the 2024 Festival des Architectures Vives highlights its potential to revolutionize sustainable 3D printing with high-performing, food-safe materials.

Addressing Plastic Waste and Sustainable Design

In the modern world, plastic waste poses a significant environmental challenge, contributing to no less than 44% of total waste. The 3D printing community has a unique opportunity to make manufacturing methods more sustainable, but this requires innovative solutions that do not compromise on quality. The 2024 Festival des Architectures Vives (FAV) highlighted this challenge through its installations, demanding eco-friendly designs that also engage and inspire the public.

Atelier DARN, known for its inventive approach to architecture and design, faced the challenge head-on. Their goal was to create an installation that not only captivated audiences but also demonstrated the potential of sustainable materials. They needed a solution that would meet the aesthetic and functional demands of their project while significantly reducing environmental impact.

KOBAK Bilge – AYAN Peker – CAG Simay

With kind permission of use: ©photoarchitecture.com – PAUL KOZLOWSKI

The Solution: Ultrafuse®️ rPET by BASF Forward AM

“In our project we wanted to use a recycled material to reduce the carbon footprint of the project. At first we started experimenting with a homemade process of turning plastic bottles into filament material. But then we wanted also to incorporate an industrial base filament.”

ꟷ Simay Cag, Atelier Darn

To address this challenge, Atelier DARN turned to Forward AM’s Ultrafuse®️ rPET, an innovative filament made from recycled PET post-industrial waste. This filament represented a sustainable alternative to traditional materials made from virgin raw materials. The development of Ultrafuse®️ rPET was driven by the need to create a filament that not only reduced environmental impact but also performed on par with conventional materials.

Ultrafuse®️ rPET stands out for several reasons:

- Recycled Content: Made from post-industrial PET waste, it reduces reliance on virgin raw materials.

- Performance: Components printed with Ultrafuse®️ rPET look and perform as well as those made from traditional PET filaments.

- Food-Safe: Based on food-safe raw materials (granulate), it is suitable for food contact applications according to the European Plastics Regulation.

- High-Speed Printability: With print speeds up to 150 mm / s, Ultrafuse®️ rPET stands out as the sustainable high-speed material for FFF printers.

By utilizing Ultrafuse®️ rPET, Atelier DARN could ensure their installation was both environmentally responsible and visually stunning.

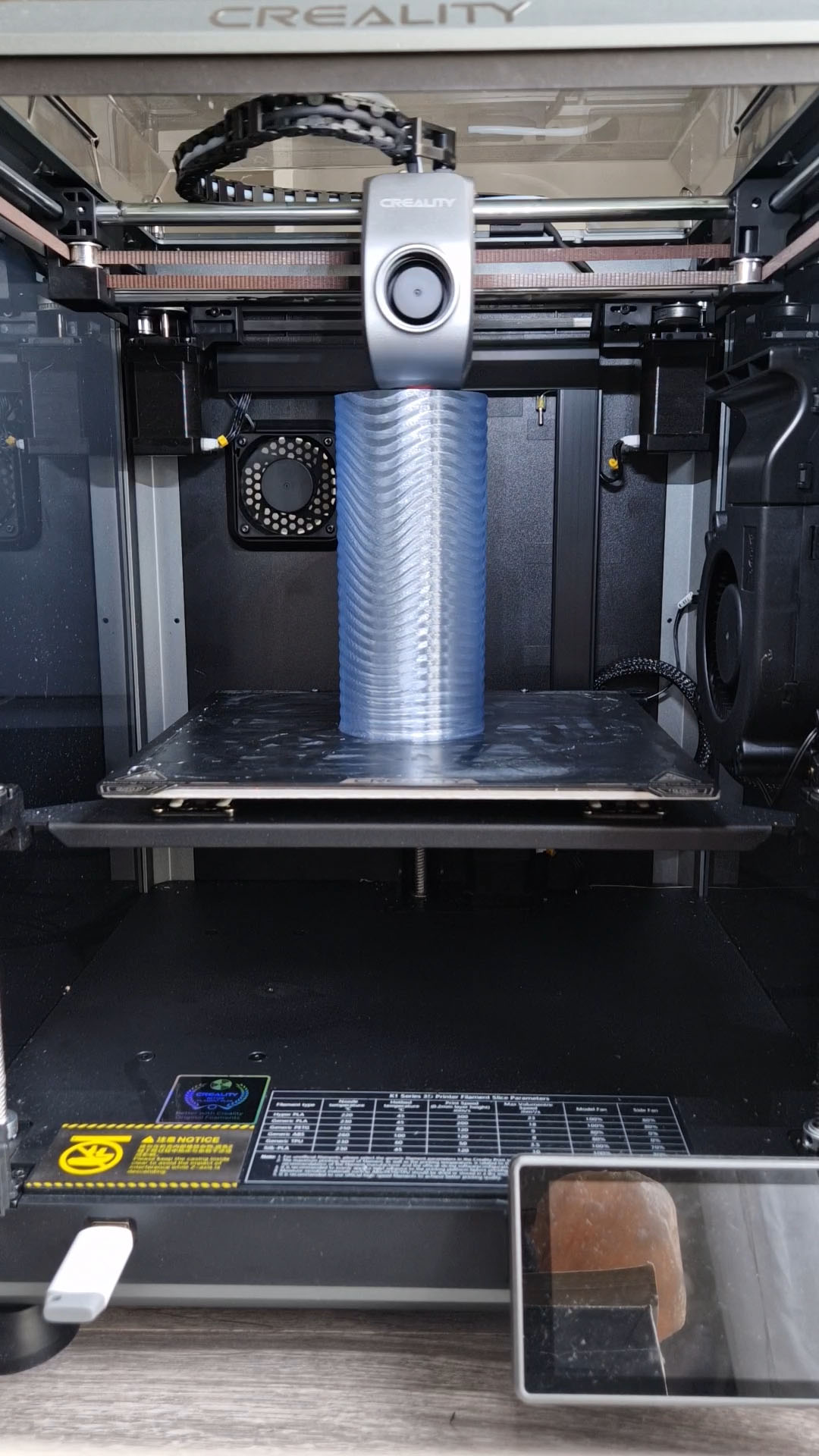

“We had been printing at different speeds since April to complete thousands of elements in a short space of time using a high-speed 3D printer. Actually, we had some doubts before starting the process. But during the process with the material, we have seen that everything goes smoothly: both with individual elements and with experiments where we printed 9 elements at once, which took five to six hours to build at high speed. Actually, there were no problems during the process and we were very happy with the results, how precise the material was.”

ꟷ Peker Ayan, Atelier Darn

The Result: RHUBARB at FAV 2024

The result of Atelier DARN’s efforts was RHUBARB, a captivating installation that won the public prize at FAV 2024. Erected in the historic courtyard of Hôtel d’Aurès in Montpellier, France, RHUBARB features 1,000 pieces of 3D-printed elements created from eco-friendly PET filaments. These elements, varying in size and color, reflect the hues of Montpellier and symbolize human diversity and inclusivity.

Engaging the Audience

Inspired by the Olympics, RHUBARB celebrates the role of spectators, transforming visitors into active participants in the art. The pavilion acts as an observer, mirroring and reflecting the movements of its visitors. The name “Rhubarb” signifies the ambient background noise that completes a film scene, much like the audience’s presence completes the festival experience.

The installation also incorporates elements of sound and kinetic sculpture, transforming viewers’ movements into a symphony of audio experiences accompanied by light displays. This interactive aspect encourages participants to physically engage with the artwork, creating a dynamic and immersive experience.

Highlighting Sustainability

At the core of RHUBARB’s success is its commitment to sustainability. In addition to Ultrafuse®️ rPET, Atelier DARN utilized handcrafted PET filament made from home waste PET bottles and a plant-based material made from biodegradable miscanthus. These materials collectively highlight the transformative potential of sustainable design practices.

RHUBARB’s use of Ultrafuse®️ rPET underscores the feasibility of creating high-quality, eco-friendly designs. The installation not only captivated audiences but also set a new standard for sustainable architecture and design, demonstrating the potential of recycled materials in creating engaging and responsible art.

Conclusion: Paving the Way for Sustainable Design

RHUBARB by Atelier DARN is a testament to overcoming environmental challenges through innovative solutions. By adopting Forward AM’s Ultrafuse®️ rPET, Atelier DARN successfully created an installation that is both sustainable and captivating. The recognition of RHUBARB at FAV 2024 highlights the importance of integrating environmental consciousness into architecture and underscores the potential for 3D printing to revolutionize material use and sustainability.

As we look to the future, installations like RHUBARB pave the way for a more sustainable and interactive approach to art and architecture. They demonstrate the possibilities that arise when creativity and environmental consciousness come together, offering a vision of a more inclusive and sustainable world.

“We are really grateful for our collaboration, because through their filament, Ultrafuse® rPET, we were able to create the industrial base for this artwork we’ve created. We wanted to show the world that there are other ways to build things and that we should collaborate for a better future.”

ꟷ Bilge Kobak, Atelier Darn

Share this page

Next Steps

Reference Links and Documents

- Product Leaflet

- Technical Data Sheet: EN, FR, ES, DE, ZH

- Safety Data Sheet: EN, other languages

- Printing Profiles

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!