Ultrafuse® Pellets rPETG

The Ultimate Choice for Sustainable, Cost-Effective 3D Printing

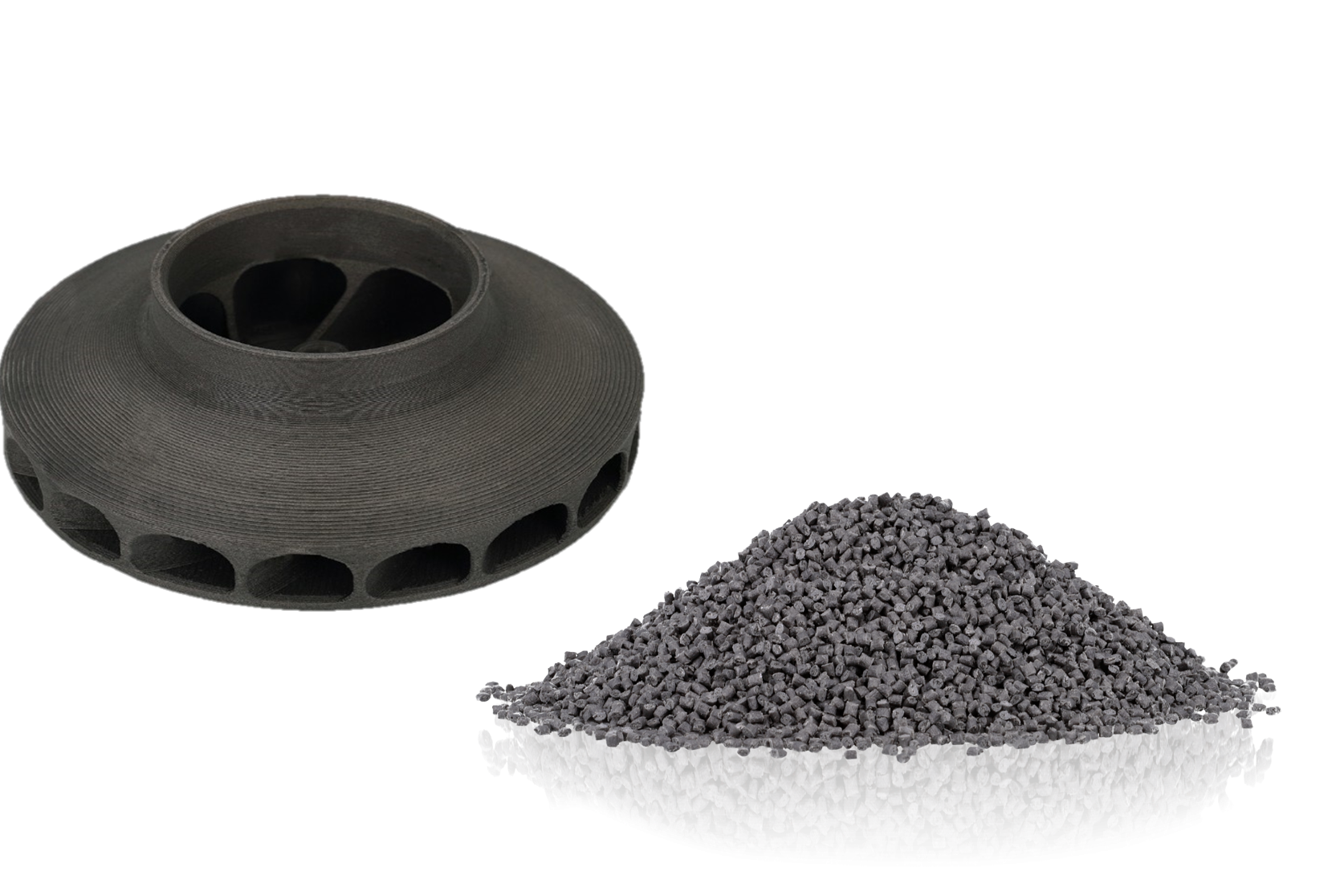

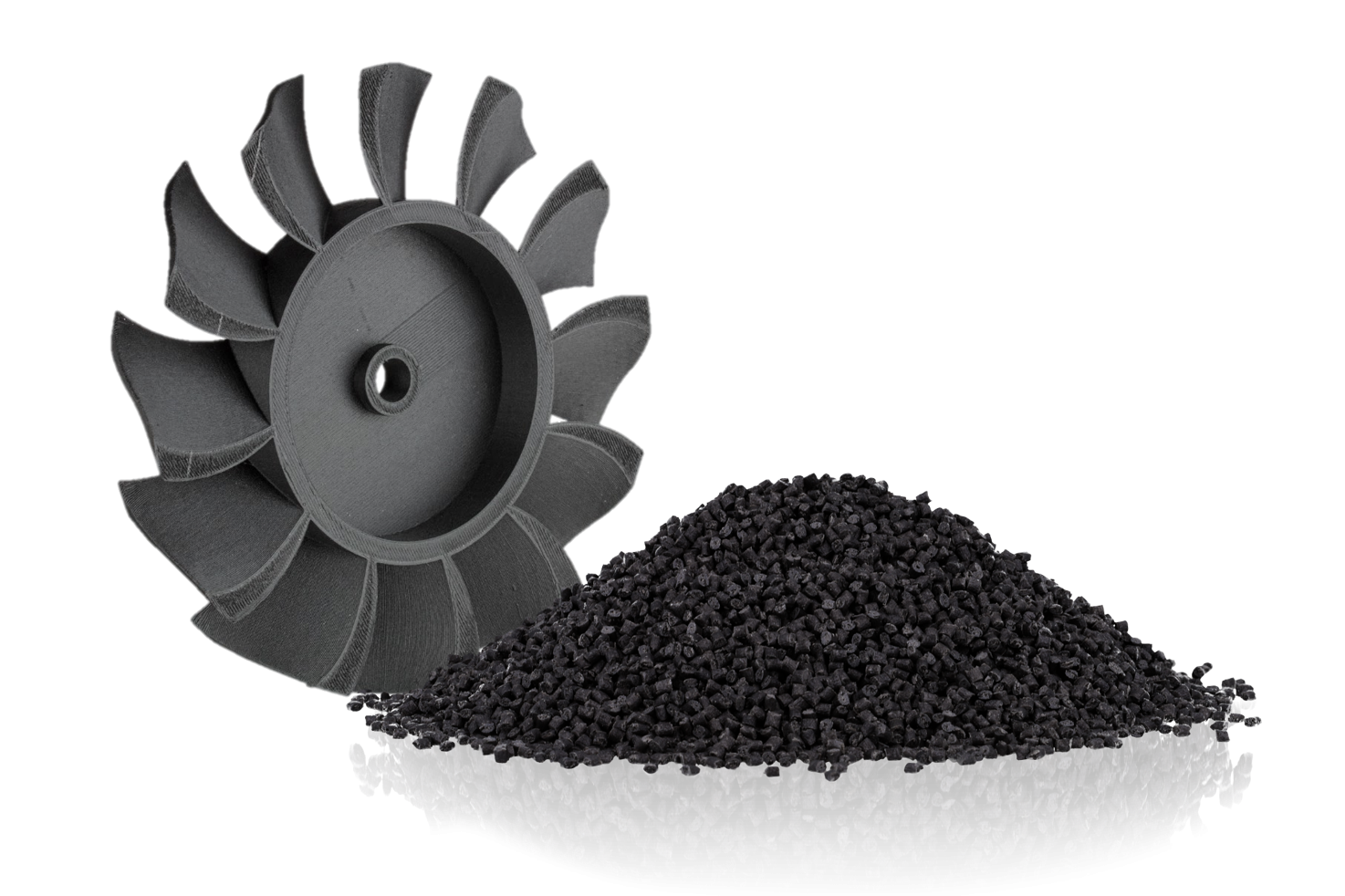

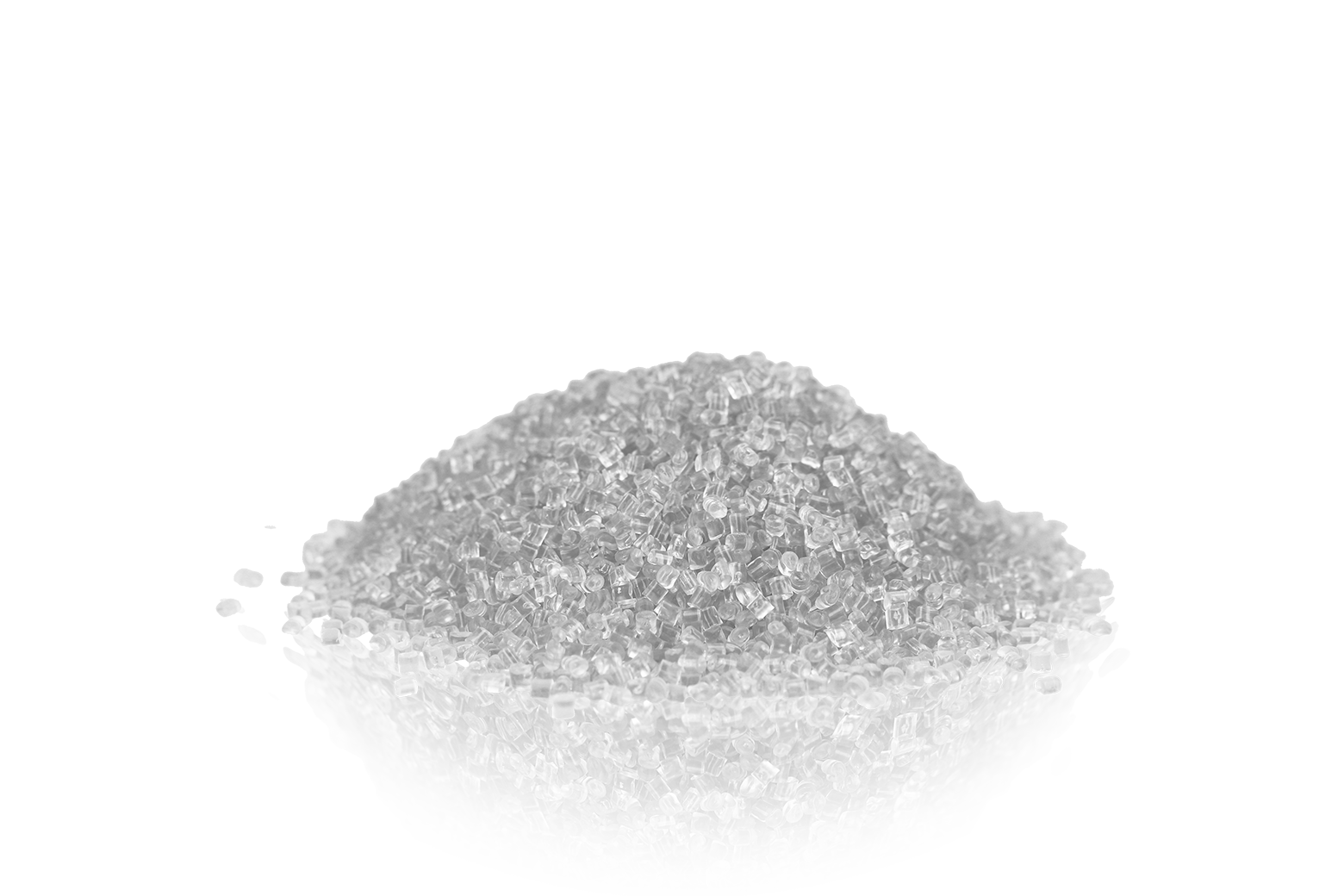

Discover Ultrafuse® Pellets rPETG, the premier material for sustainable, cost-effective, and time-saving production of large components. Engineered for user-friendliness, this material is perfect for both beginners and seasoned 3D pellet printing enthusiasts, excellent surface quality, transparency, and mechanical properties, making it the first choice for large-scale additive manufacturing (LSAM) and sustainable 3D printing projects.

Material Details

-

- Product Leaflet

- Technical Data Sheet: EN, DE

- Material Safety Data Sheets

- Recycled Content Declaration

Optical Excellence and Stability

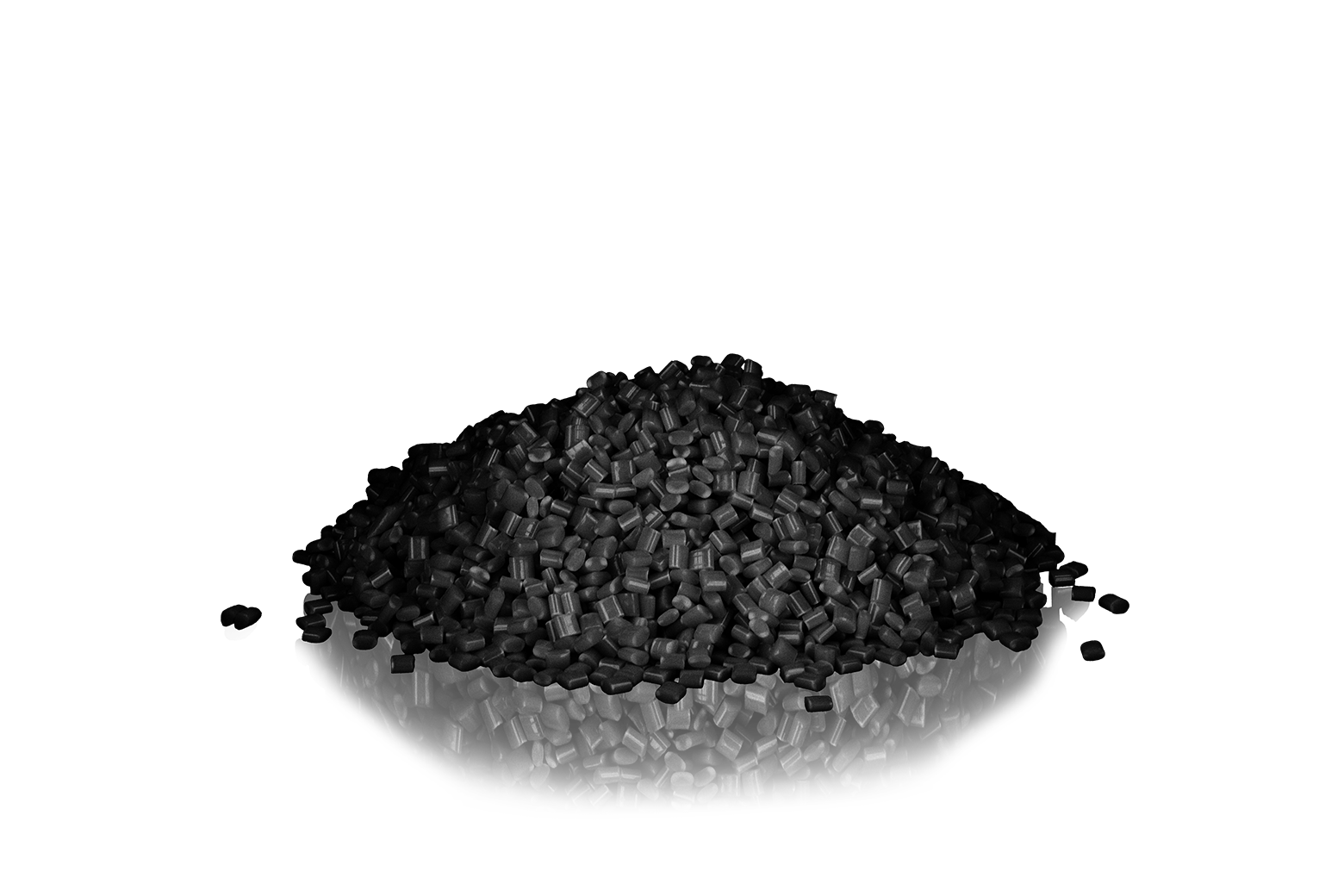

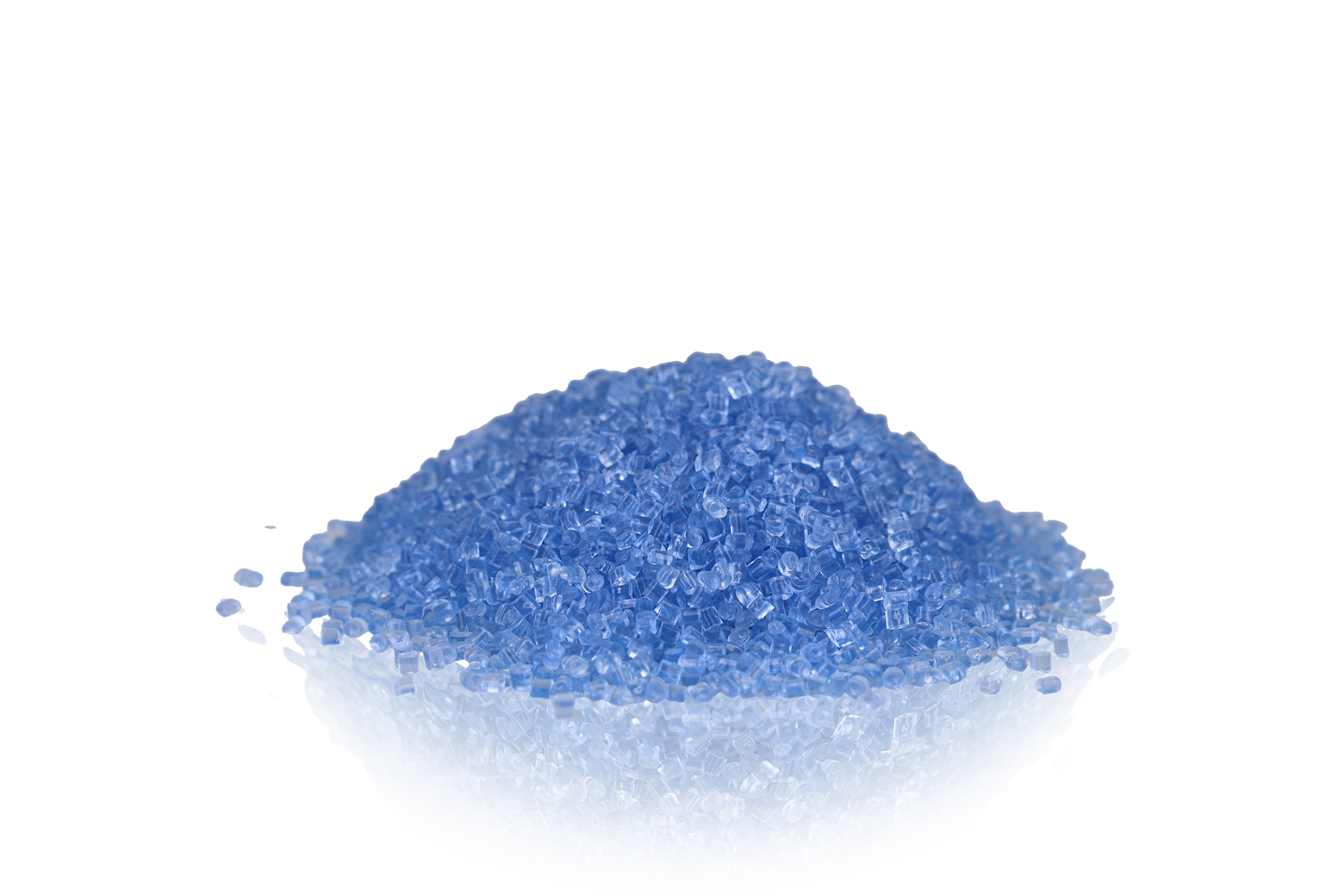

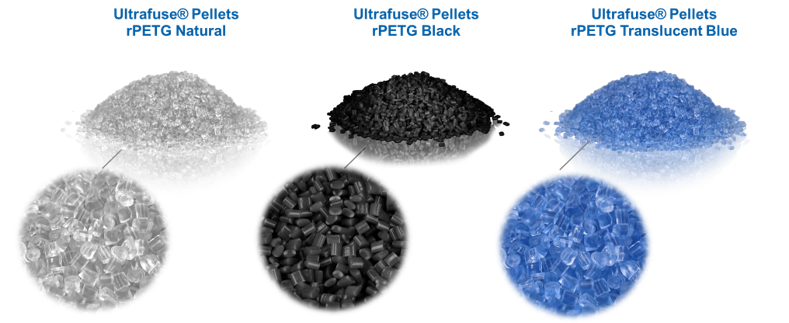

Available in its natural colorless form with high transparency, in translucent blue and solid black, Ultrafuse® Pellets rPETG delivers a high-gloss finish ideal for applications demanding superior optical appearance and surface quality.

With low to no warping or distortion, Ultrafuse® Pellets rPETG combines excellent surface quality, transparency, and mechanical properties, making it the first choice for large-scale additive manufacturing (LSAM) and sustainable 3D printing projects.

Sustainable, Traceable and Food Safe

No less than 44 % of total waste* is generated by plastics. The 3D printing community provides a powerful opportunity to make current manufacturing methods more sustainable, so we have challenged ourselves again to create a pellet grade made from recycled material that is a serious alternative to virgin raw materials.

Made from recycled and glycol-modified polyethylene terephthalate (PET) derived from traceable post-industrial waste, Ultrafuse® Pellets rPETG ensures food contact safety through a unique recycling process.

This modification enhances the material’s flexibility, impact resistance, and processing ease while maintaining its clarity, making PETG ideal for applications requiring durability, transparency, and easy manufacturing.

Benefits at a Glance

- Recycled: Traceable industrial waste source

- Food Grade: Suitable for food contact application

- Superior Optical Appearance: High gloss, low haze and high transparency

- Low warp and Glossy Finish: Ease of printing for high detail and large-scale prints

- Project stability: Excellent batch to batch stability

- Pre-dried: Pellets come pre-dried ready to be processed

- Reliable Delivery: Ready to ship after order, available in industrial quantities

Example Applications

- Decorative Parts

- Automotive Parts

- Prototyping

- Architectural Parts

Material Properties*

- Tensile Strength (MPa): 14.7 (ZX), 38.6 (XY)

- Flexural Modulus (MPa): 829(ZX), 1551 (XZ), 1662 (XY)

- Elongation at Break: 1.2% (ZX), 4.3 %(XY)

- Impact Strength Izod notched (kJ/m2): 1.5 (ZX), 3.3 (XZ), 4.4 (XY)

- Impact Strength Izod unnotched (kJ/m2): 4.4 (ZX), 21.9 (XZ), 48.2 (XY)

- HDT @ 0.45 MPa: 71°C

Recommended Print Settings*

| Recommended Extrusion Parameters | |

|---|---|

| Zone 1 Temperature | 195 - 200 °C |

| Zone 2 Temperature | 200 - 235 °C |

| Zone 3 Temperature | 195 - 235 °C |

| Nozzle Temperature | 195 - 235 °C |

| Extrudate Temperature | 200 - 245 °C |

| Drying Recommendations | |

|---|---|

| Temperature | Min. 55 °C; Max. 65 °C (prevent sticking) |

| Time | 6 - 13 h |

| Condition | 200 - 500 ppm |

* The product data is provided in good faith and represents typical properties based on our current knowledge of the Ultrafuse® rPET filament and experience; these data are not to be construed as specification limits or mini- mum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse ®products for the intended application.

Sustainability Check

Lifecycle assessment available

Generally recyclable

Recycled Material

Recycled Packaging

Use Case of Ultrafuse® rPET

RHUBARB by Atelier DARN: Championing Sustainability with Ultrafuse®️ rPET at FAV 2024

Using Forward AM's Ultrafuse®️ rPET filament, Atelier DARN's RHUBARB installation of 1,000 3D printed elements triumphed at the 2024 Festival des Architectures Vives (FAV) by winning the Public Prize.

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

More Ultrafuse® Pellets

Ultrafuse® Pellets PC GF30

Ultrafuse® Pellets PC GF30: Flame Retardant Micro Pellets, Glass Fiber Reinforced

Benefits at a Glance

- Flame Retardant

- High Stiffness, Glass Fiber Reinforced

- Temperature Stability and UV Resistance

Ultrafuse® Pellets PP GF30

Ultrafuse® Pellets PP GF30: High-Performance Micro Pellets, Glass Fiber Reinforced

Benefits at a Glance

- Excellent Chemical Resistance

- High Stiffness, Heat Resistance, and UV Stabilization

- Low Moisture Uptake