Virtual Engineering and Simulation

Virtual Engineering Improves the Success Rate, Reducing Time and Costs

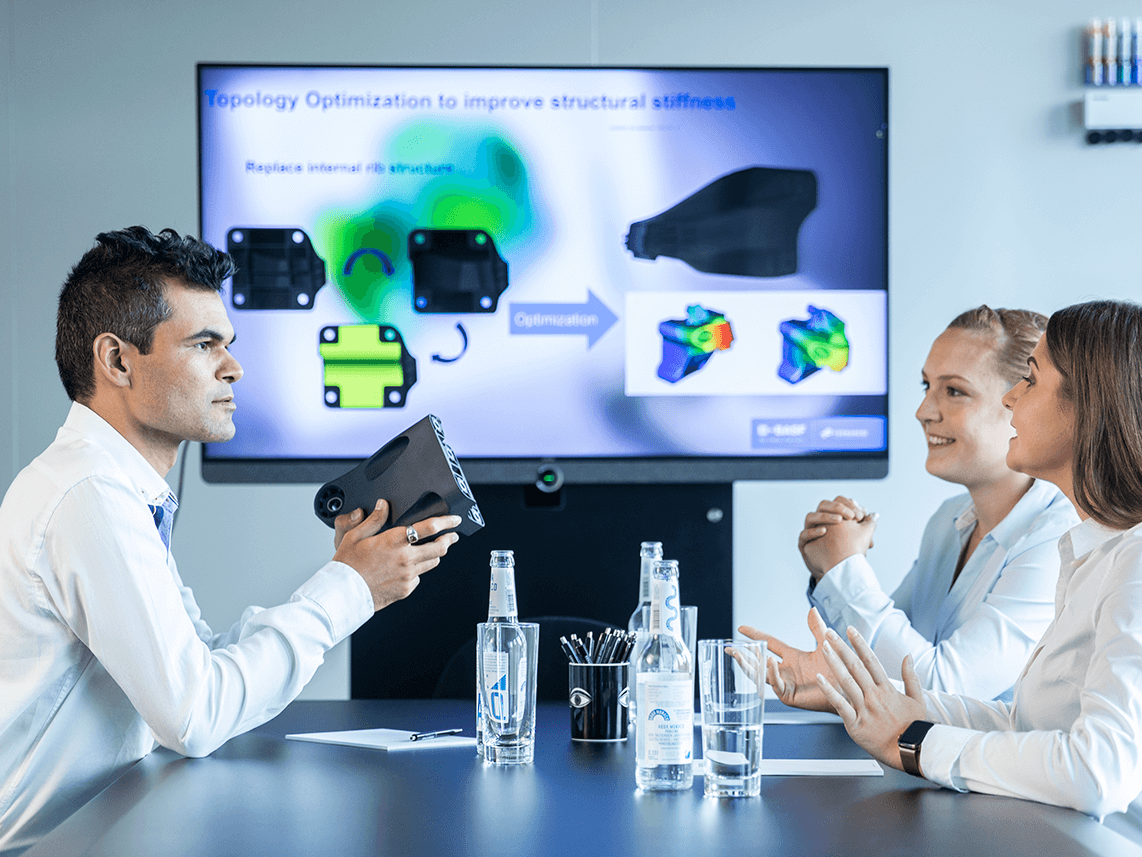

Simulation for additive manufacturing is a valuable step in the production of 3D printed parts.

Engineers and 3D printing specialists work closely with designers to fully understand the perfect part orientation and support structure design, in order to reduce the number of iterations and tests during construction.

Through our part and process simulation service, we help our customers save time and costs: We identify and eliminate weaknesses ahead of production, thus reducing the risk of part failure. Our experts identify areas vulnerable to warping, delamination, and excessive deformation by leveraging a diverse set of detailed material models.

Through our virtual engineering service, we are able to increase your success rate by predicting the thermo-mechanical behaviour of the materials during printing.

The challenge of mechanical material modelling is to find and describe the correlation between stress and strain. While in linear material models the stress is directly proportional to the strain, under real-world operating parameters the correlation is different. Materials usually show nonlinear behaviour and respond differently according to temperature variations, strain rates, load vectors, and load types.

We help our customers harness their components’ highest potential by developing non-linear material models for our AM materials and numerically optimizing the build orientation.

Benefits at a Glance

- We optimize your part’s weight and function

- We enable radically new AM-based design approaches

- We consider the complete product lifecycle

- We select the ideal AM material specific to your component’s required performance profile

Solutions

- Process Simulation

- Material testing and modeling

- Structural Design

- Unique lattice-based functional Design Structural Simulation

- Build job optimization

- NVH Optimization

How Additive Manufacturing comes to Life

Project Reference

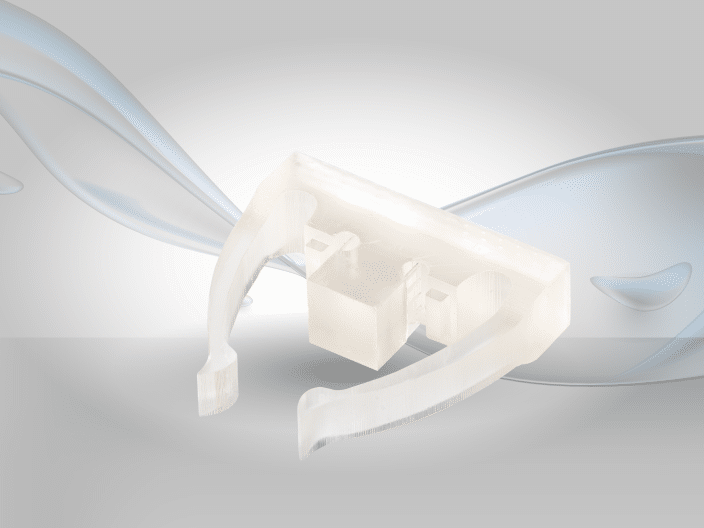

Material used: Ultracur3D® RG 35

Project description and challenge: A major chemicals group’s Adhesive Research specialists contacted the Forward AM team. The customer was currently using several adhesive tape strips to fix parts together. The problem is that this method required exhaustive preparation, did not deliver robust results, and the components sometimes fell apart. We developed a Snap-Fit design to do the same job faster, more reliably, and requiring fewer manual steps.

Our solution and added value for the customer: We applied virtual engineering to understand the problem, develop a different, new and unique solution and optimize it through Numerical Free Shape Optimization. Changing the contour reduced surface stress by 24%, which delivered a major improvement in construction integrity.

Lattice Engineering possibilities with Ultrasim®

Chances

- Cuts development time and cost by minimizing design and test iterations

- Quickly identifies the optimal lattice structure for your new component design

- Identifies the optimal balance of component performance and weight

Example Project

Goal: Find the lightest and thinnest lattice fulfilling Level 1 and/or Level 2 CE protection for motorcycle clothing DIN1621-2

Design Variables e.g. Diameter, Thickness, Lattice Type

Simulation provided a design space revealing the parameters for which the lattice can fulfill the DIN 1621-2 requirements

Next Steps: Lattice validation by real world testing

Print your Parts with Forward AM Materials!

Discover our comprehensive services and solutions here

Related Use Case and Whitepaper

Increasing Part Stiffness of Lightweight FFF End-Use Parts by Simulation

In Fused Filament Fabrication (FFF), print settings are usually calculated with algorithms of 3D printer related slicing software. Although often…

Next Steps

Get your customized lattice here

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!