Post Processing

Turn your 3D Printed Part into a Marketable Product

With our broad range of post processing options we identify the best way to finish your part.

Post processing gives you a wealth of possibilities to enhance the appeal, durability, surface roughness and overall quality of your 3D printed part. Let us support you in identifying the ideal surface finish for your specific application to give your product the desired look and feel.

Within our post processing methods, you can choose to buy a standard product and receive instruction on how to use it, or alternatively use our end-to-end solution support to develop your own individual post-processing method.

We are able to consult you, how to set up your own post processing operation or identify the right partner to offer the service for you.

We identify the best possible way to finish your part

Depowdering / Support Removal

- Development support of different processes

- Industrial scale up consulting

Surface Smoothing

- Mechanical and chemical methods available

- Improve material performance

- Chemical Smoothing for Polymers

Coating and Dyeing

- Solution depends on the material and desired surface

- Specific coating requirements for printed parts to improve properties and color

- Coating product offering and color development service available

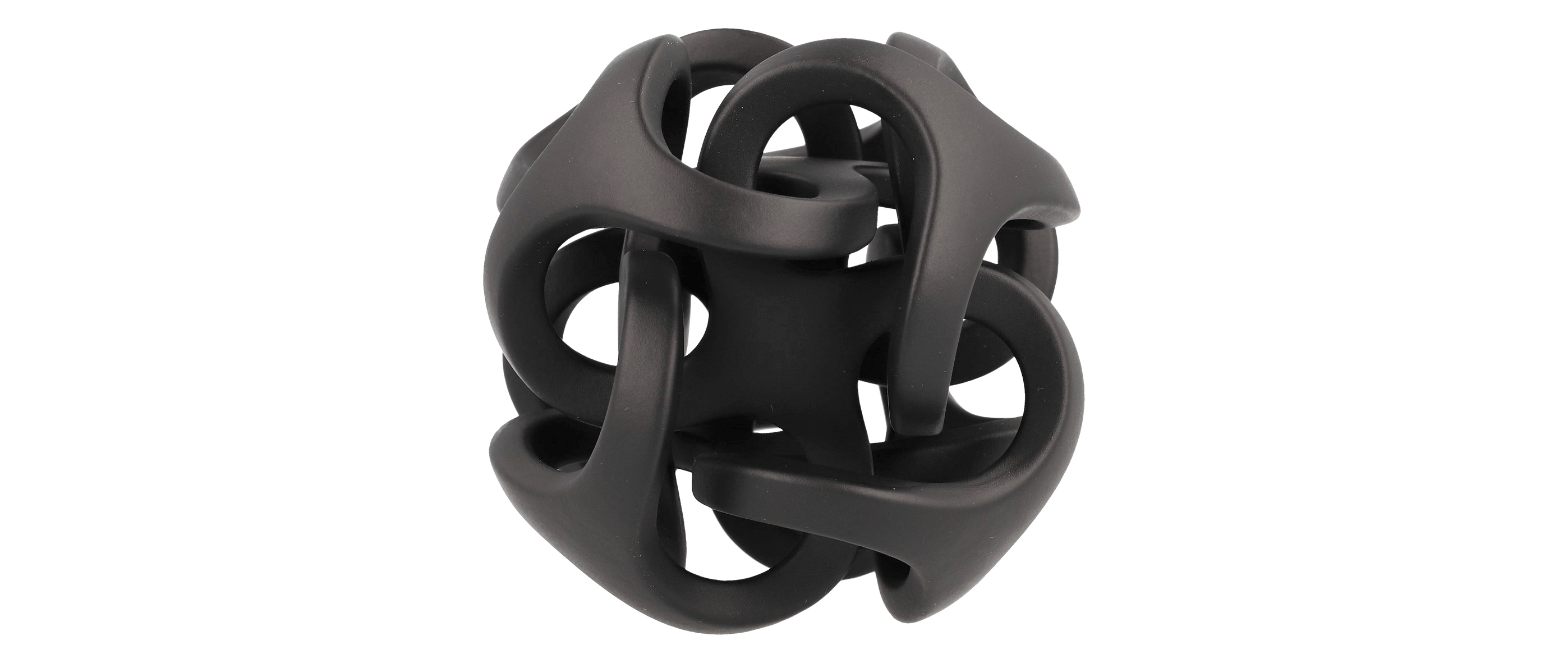

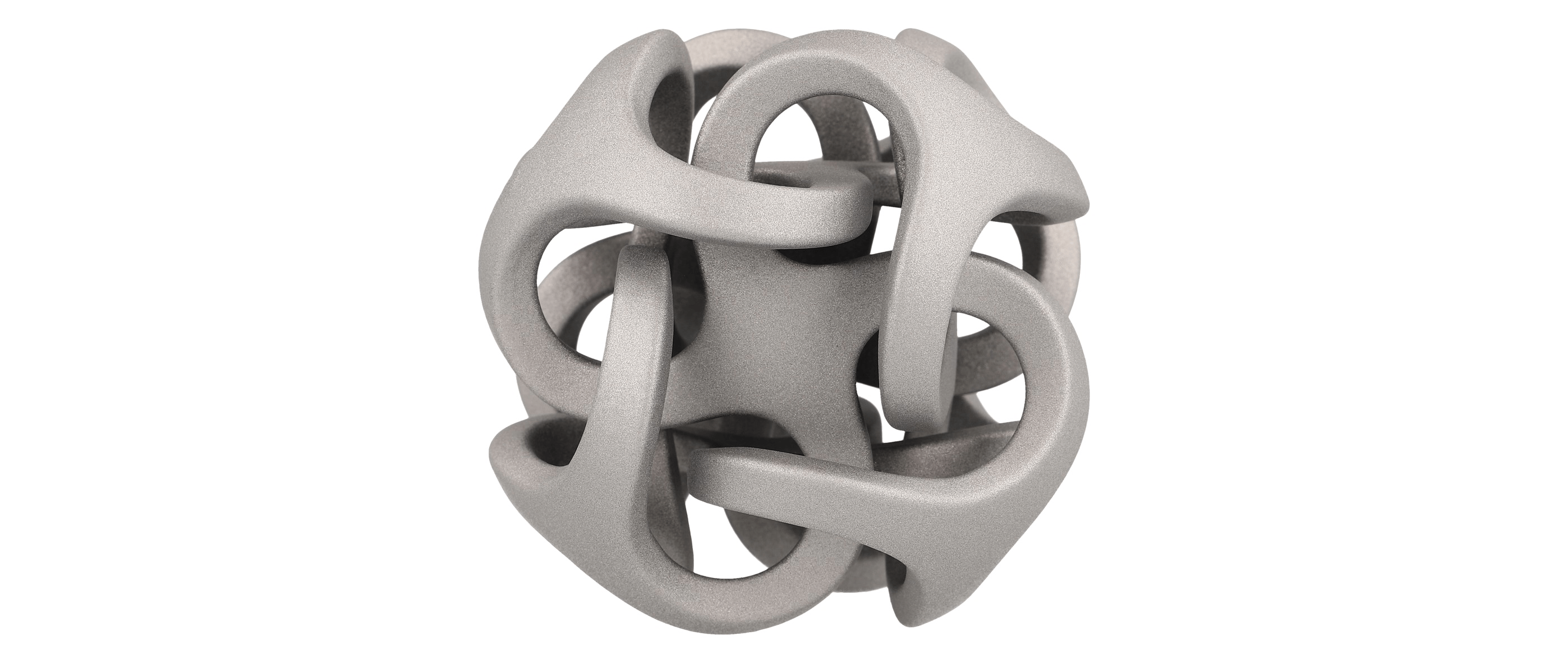

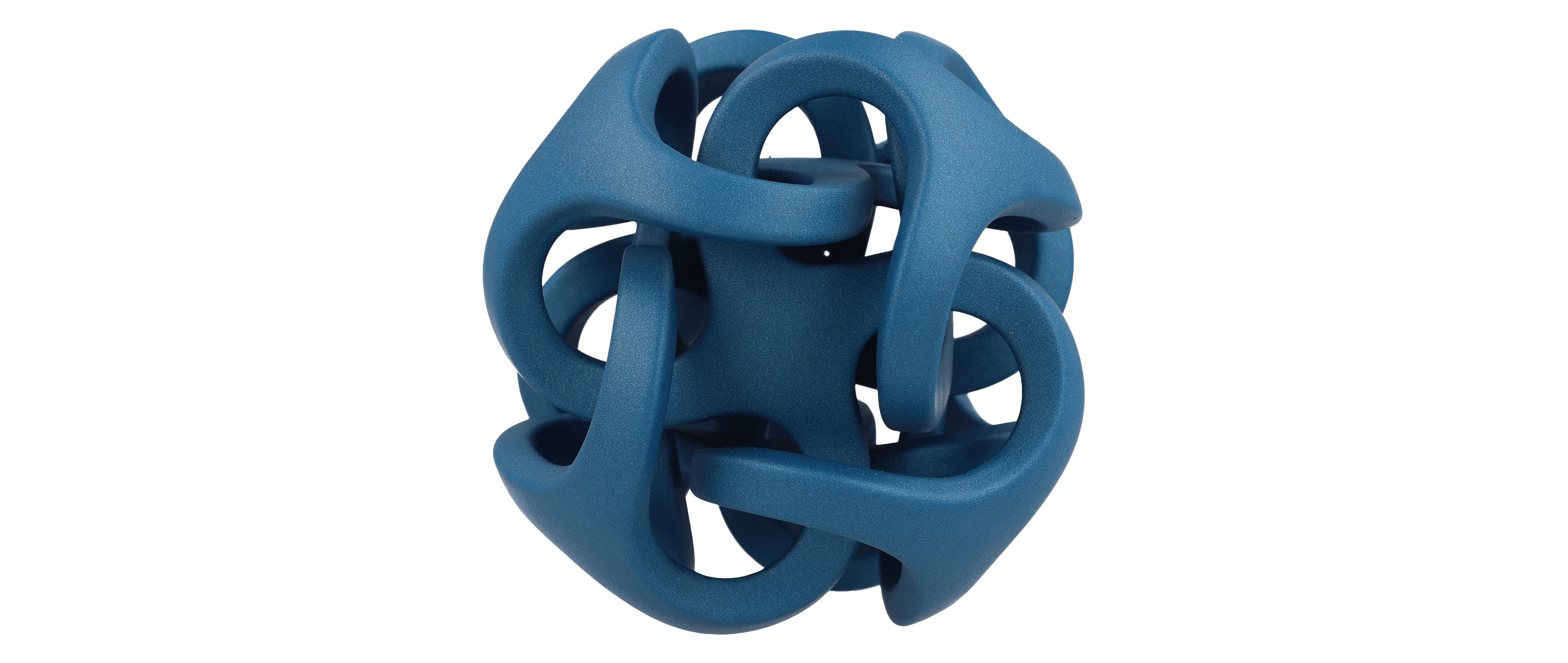

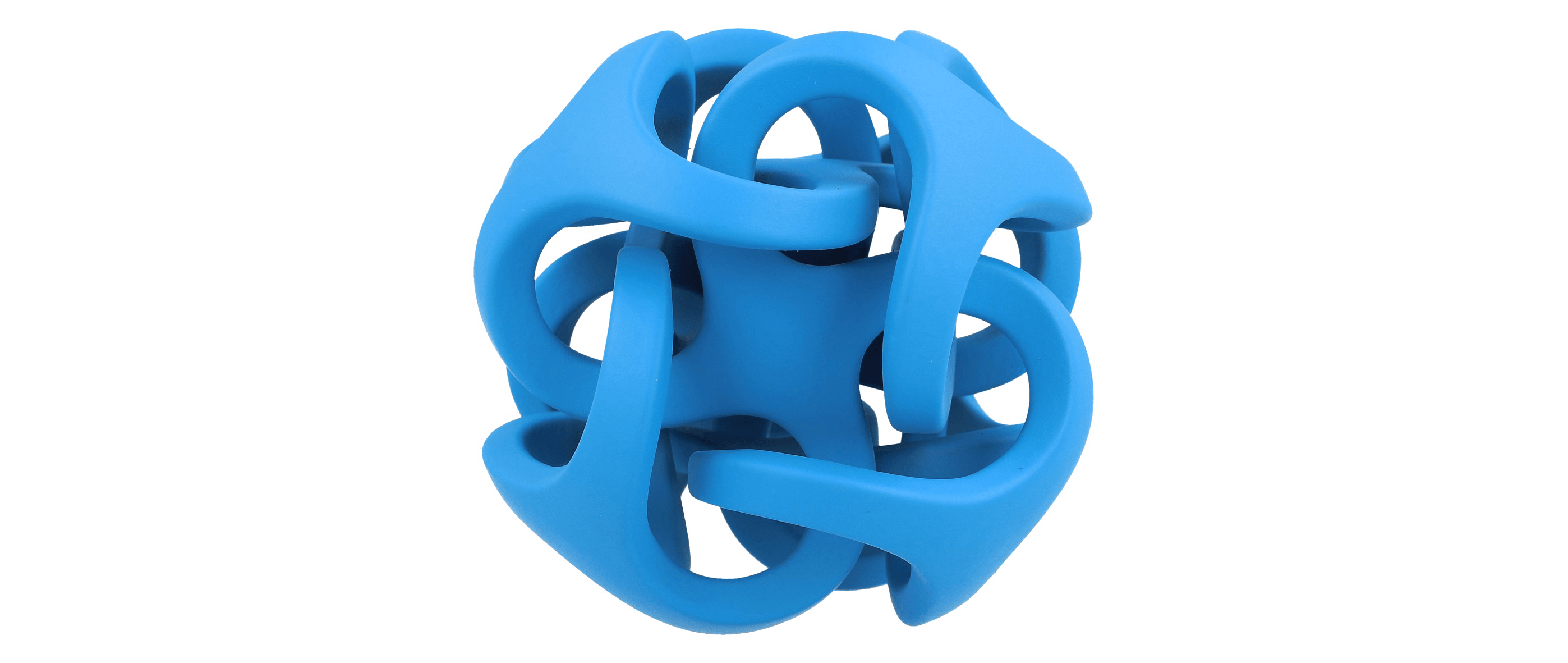

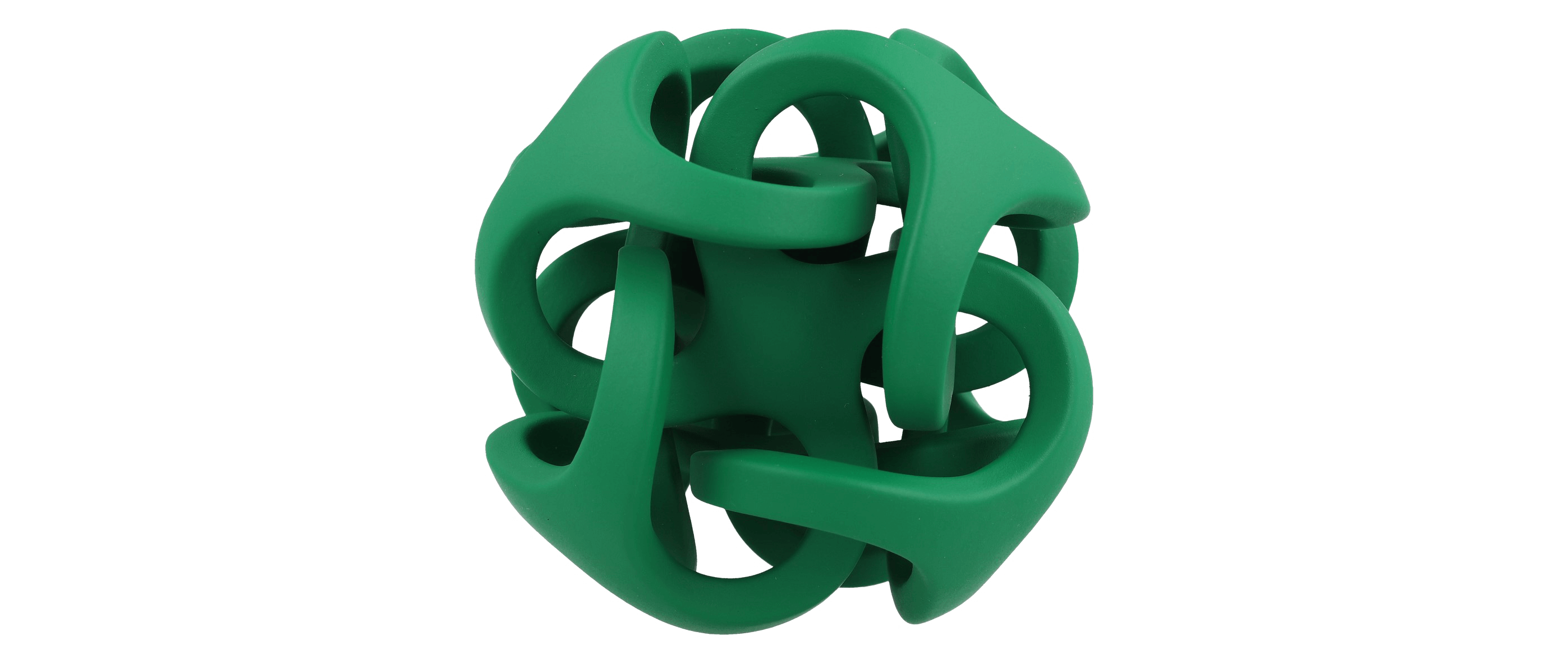

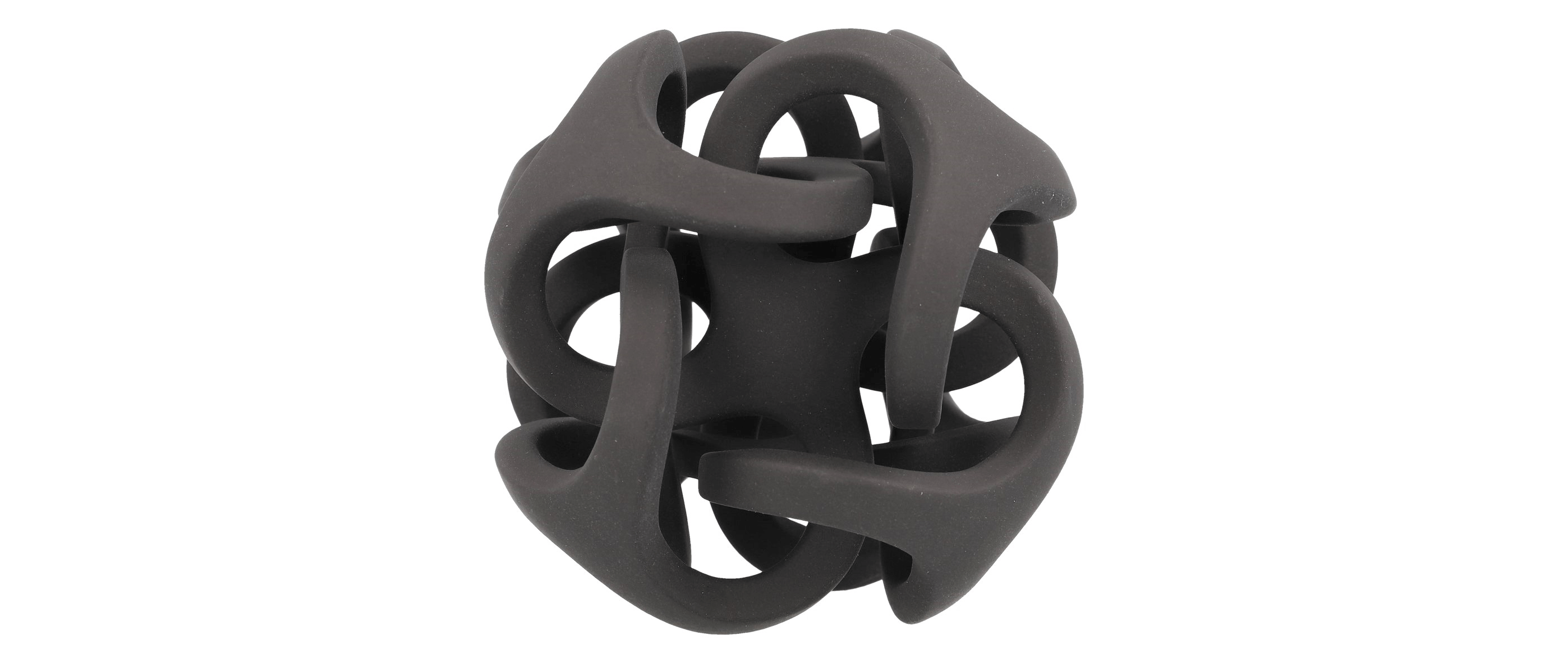

Ultracur3D® Coat F - Flexible coating to enhance appearance and improve part properties

The Forward AM Ultracur3D® Coat F is a flexible waterborn 2k-basecoat designed to offer exceptional flexibility for elastic 3D Printing Materials and enables new possibilities for advanced applications – from functional prototyping through to end-use serial production parts. Together with BASF Coatings GmbH we can offer outstanding technical support and an extensive range of colors to identify the ideal surface finish for your specific application.

Benefits at a Glance

- Large color portfolio

- Customized color development

- Excellent adhesion

- Outstanding flexibility

- Compatible with a wide range of materials

- Skin contact safe

Fields of Application

- Sports protection equipment

- Footwear

- Orthopaedic models

- Car interior components

- Tools, grippers and pipes

Main Properties

| Form | Liquid |

| Gloss | <10 |

| Substrate | TPU, PA, Resins |

| Hardener | Ultracur3D® Hardener F |

| Thinner | DI-Water |

| Mixing ratio by volume | 100:10 |

Available colors

Jet Black

Metallic Silver

Pure White

Purple Violet

Pure Red

Canola Yellow

Metallic Blue

Light Blue

Grass Green

Transparent

- Flexible: Color matching only requires a color sample, RAL-Code or Pantone-Code.

- Diverse: Almost any shade can be covered and color effects can be realized.

- Leadtime: Customer feedback loops in the development process for a short lead time.

- MOQ: Customized colors can be ordered at an MOQ of 1kg

Ultracur3D® UV Adhesion Promoter

The Forward AM Ultracur3D® UV Adhesion Promoter is a solvent-borne UV-Primer to improve the adhesion for rigid 3D-Printing Materials and enables new possibilities for materials that are difficult to coat – such as Polypropylen. With our UV adhesion promoter, there is no need to develop or replace existing coating systems, as it is compatible with commercially available topcoats and clearcoats.

Benefits at a Glance

- Excellent adhesion enhancement

- Smoothens surface

- Compatible with a wide range of topcoats systems and application methods

Fields of Application

- Automotive interior

- Automotive exterior

- Consumer goods

Main Properties

| Form | Liquid |

| Gloss | High gloss |

| Substrate | PA, PP; Resins |

| Hardener | None |

| Thinner | Ethyl acetate |

Related Whitepaper

Improving Ultrasint® TPU01 part properties by PostPro® vapour smoothing

With Additive Manufacturing, it can be challenging to produce parts with professional-grade surface finishes, making post-processing an essential step in the 3D printing process.

Are you interested in collaborating with us?

We’re looking forward to hearing from you! Contact us now and we’ll get in touch.