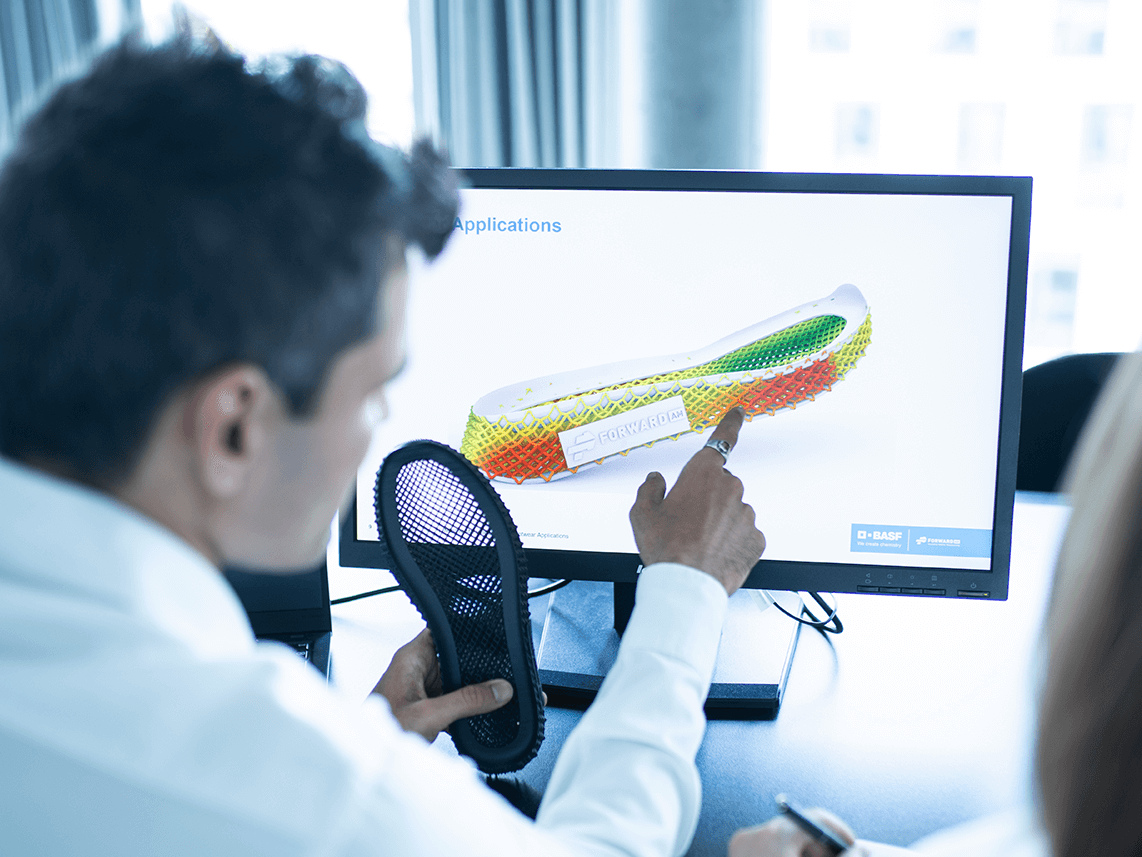

Design for Additive Manufacturing

Technology meets Material Expertise

It all starts with your idea: Rely on the deep expertise of our Service Team to help you connect the dots between design, manufacturing and material requirements of your AM application.

Together with you, our service specialists rethink a component from zero, to meet all functional requirements and identify the ideal design for additive manufacturing. At Forward AM we have direct access to an industry-leading range of technologies to put at your disposal, plus BASF’s unrivalled materials expertise. Our constant goal is to define what works best for your target application. With our Design for Additive Manufacturing, we help you make the decisive difference for your business.

We work together with Sculpteo

Benefits at a Glance

- We rethink your part from zero to identify the optimal design solution

- We enable radically new AM-based design approaches

- We enable potential cost savings throughout the entire product life-cycle

- Bionic shapes printed with AM can considerably save weight and material

Solutions

- Fluid Topology Optimization

- Reverse Engineering

- Structural Design

- Unique Lattice Design

- Advanced Slicing Technologies

- Textured Surfaces

How Additive Manufacturing comes to Life

Airflow Pipe

In the aerospace industry, every single gram counts. As a matter of fact, the #1 way for aerospace companies to save money is by reducing weight. Why? It’s simple: The lower the weight, the lower the fuel consumption and emissions.

Are you interested in collaborating with us?

We’re looking forward to hearing from you! Contact us now and we’ll get in touch.