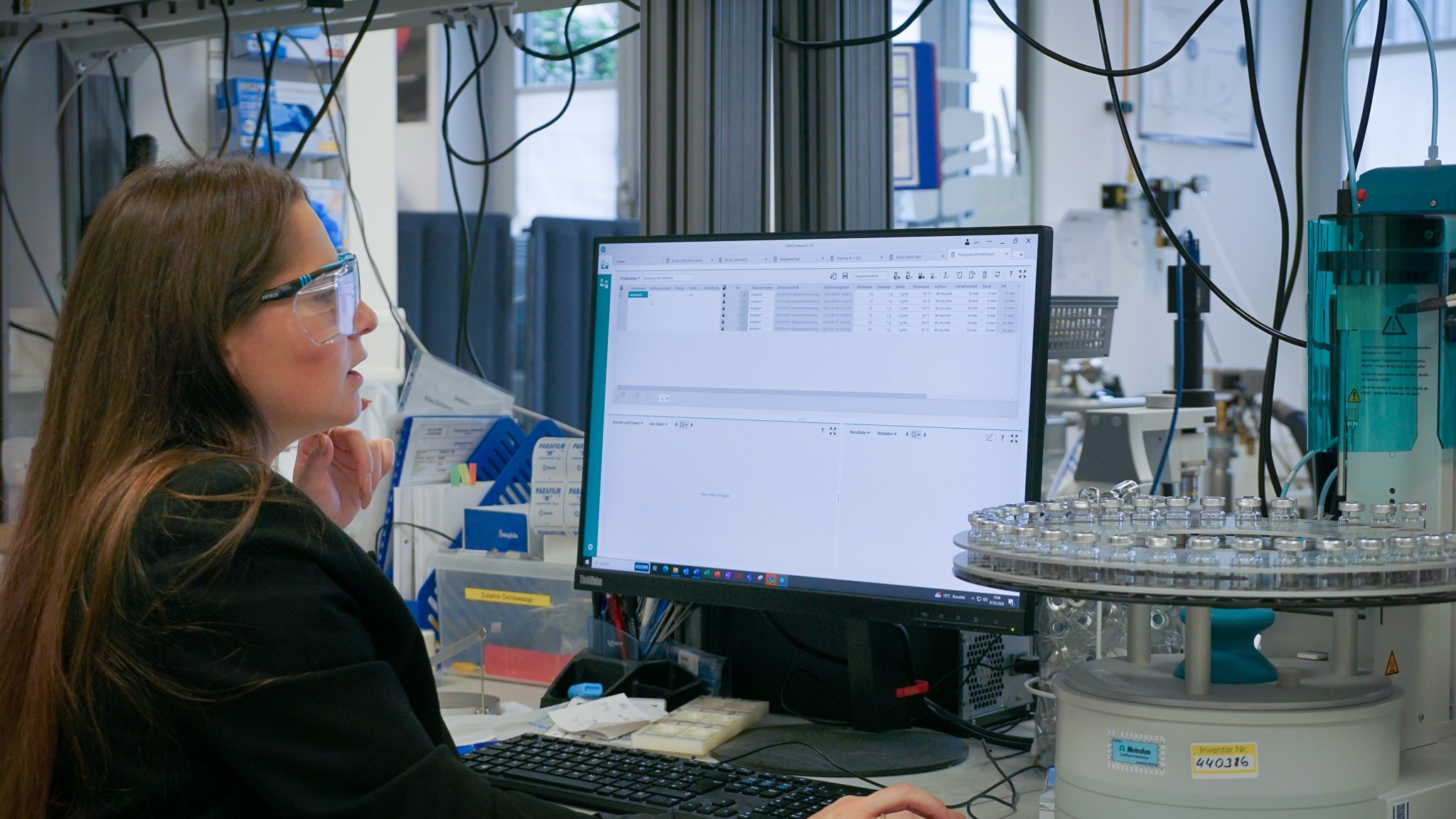

Ultrasim® 3D Testing for AM (TfAM)

Test, Trust, Print Excellence.

Discover TfAM – our Testing for AM Service, specializing in advanced materials and technologies, adhering to highest industry standards. Our comprehensive testing service for 3D printing offers a wide array of assessments tailored to your needs.

Discover our Comprehensive

Testing Portfolio

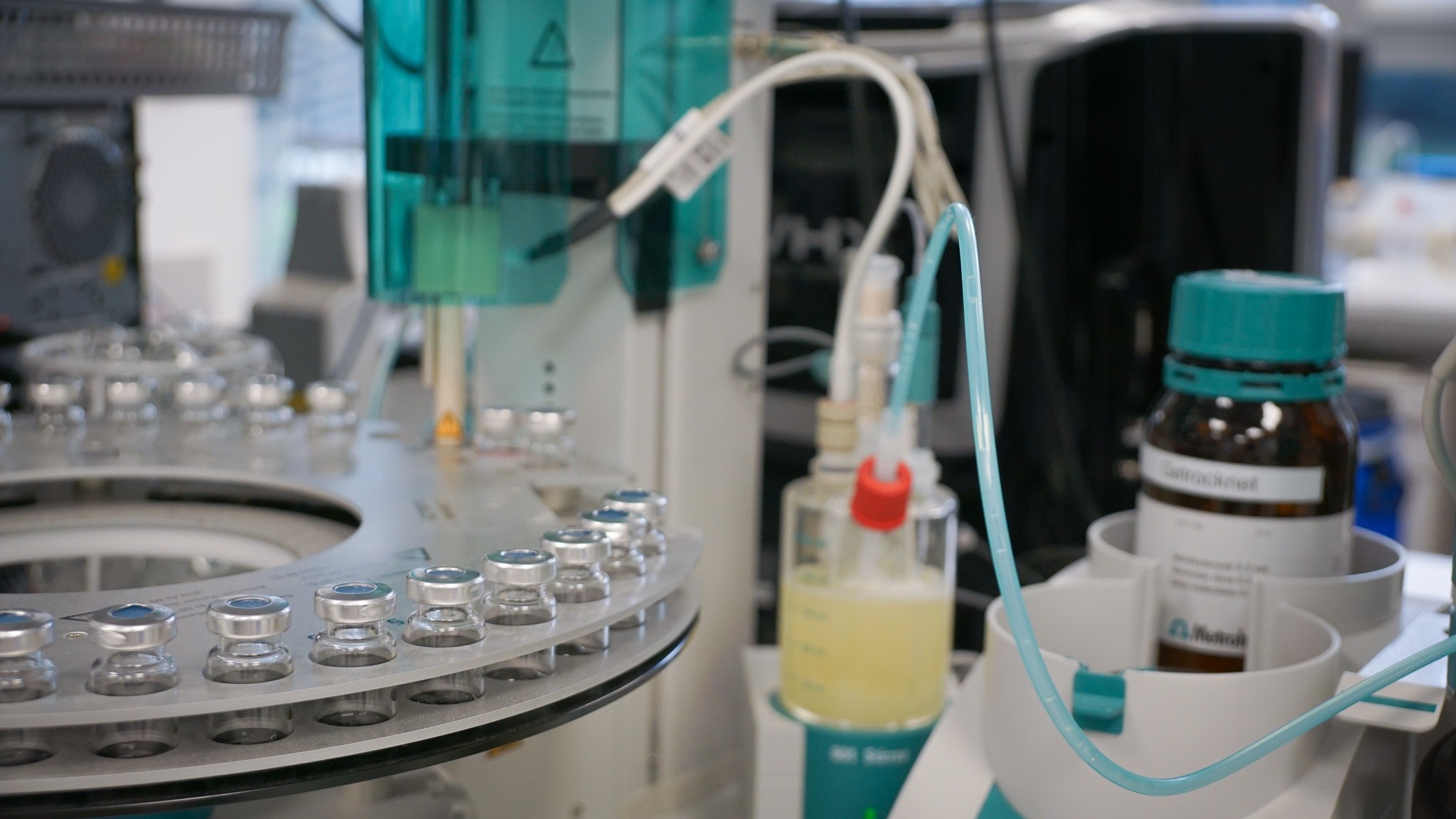

With 150+ test methods available, you have access to specialized testing equipment and the full expertise of a leading material manufacturer in 3D printing. Whether metals, plastics or elastomers, we are experienced with all material compositions in all leading 3D printing processes.

Tests Beyond

Standard

Apart from standard tests you can benefit from industry-specific tests for over 9 industries and customized parts testing for your end applications. Gain confidence in the quality and reliability of your 3D printed parts, ensuring compliance with specific industry standards and regulations.

Access Unrivaled

AM Knowledge

With BASF’s more than 150 years of material excellence, we at BASF Forward AM combine our expertise in the field of additive manufacturing (AM) as the largest independent, global material supplier in this field.

We Put Any Material to the Test

Standard Tests

- Tensile Tests

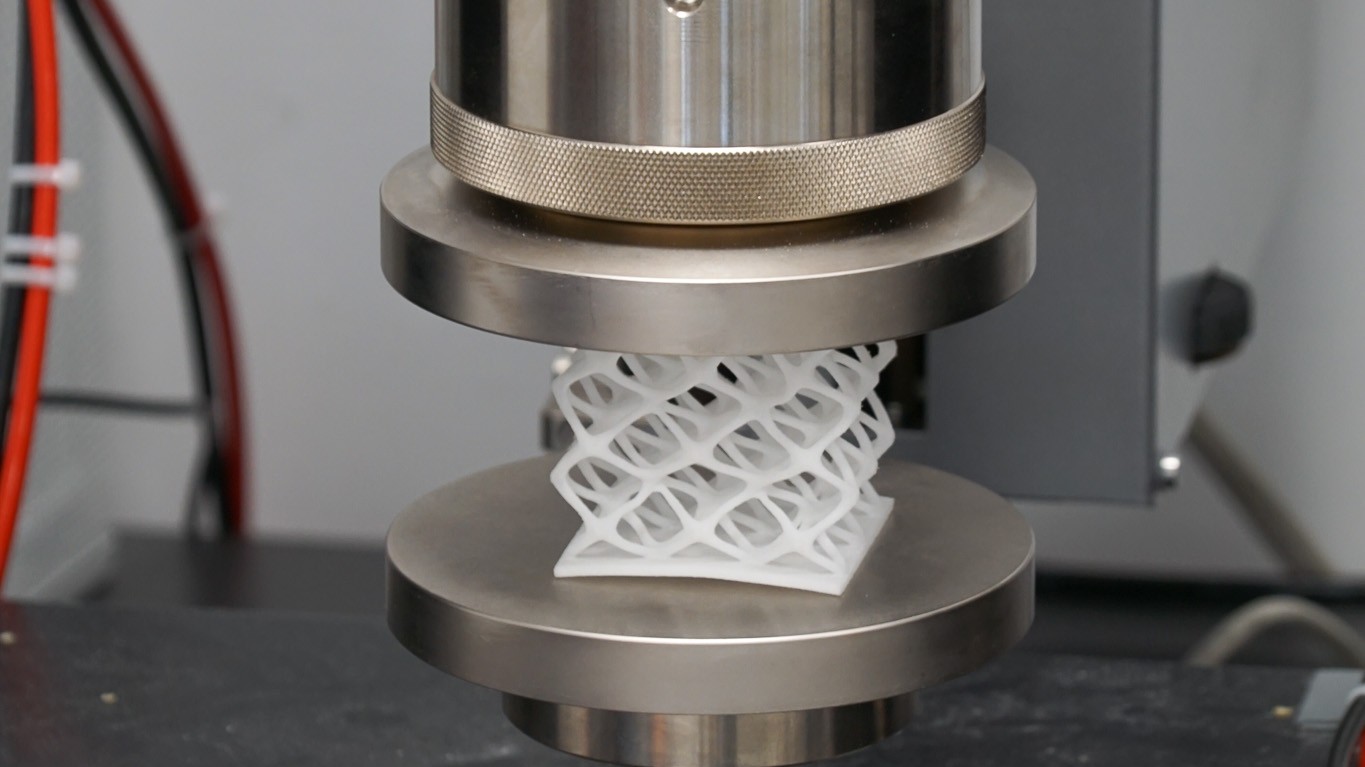

- Compression and Impact Tests

- Flexure & Fatigue Tests

- DMA, DSC and much more!

Industry-Specific Testing

- Automotive

- Transportation (e.g. Railway, Aerospace)

- Medical Devices

- Electronical Devices

- Consumer Goods

Parts Testing

- Customized Tests (e.g. crash tests of an automotive bumper)

- Life-Cycle Tests

- Footwear Tests

- Burst Tests, and much more!

Ultrasim® 3D TfAM Service Offerings

Your Expert in All AM Testing Needs

With our three different service modules, ranging from starter to enterprise solutions, we fully cater to your needs, depending on the scope of your testing needs.

Starter

Testing on Demand

Ideal for customers wanting to understand material properties on demands or want to prove that the 3D printed application fulfills testing requirements.

Premium

Monthly Subscription

Ideal for customers wanting to consistently track their quality in each print job and build up trust in their quality measures.

Enterprise

Full-Service Testing

Ideal for customers wanting or already onboarded to our material with full support from our Product Teams including a dedicated testing service to validate their machines with our materials.

Mechanical & Thermal Properties

Industry-Specific Properties

Test report as PDF

Priority Testing

Testing Consultancy

Print Parameter Optimization

Optional Add-on:

Customized Parts Testing

Testable AM Materials

- BASF Forward AM materials

- 3rd party material

- BASF Forward AM materials

- 3rd party material

- BASF Forward AM materials

Testable AM Technologies

MJF/ SLS/ LCD/ DLP/ FFF

What we need from you

3D Printed Samples + Your Chosen Test Method

Price

3-Months-Subscription:

- 3.000€/ 3 Months (MOQ)

- 15% Discount on All Tests

-

12-Months-Subsciption:

- 12.000€/ 12 Months (MOQ)

- 25% Discount on All Tests

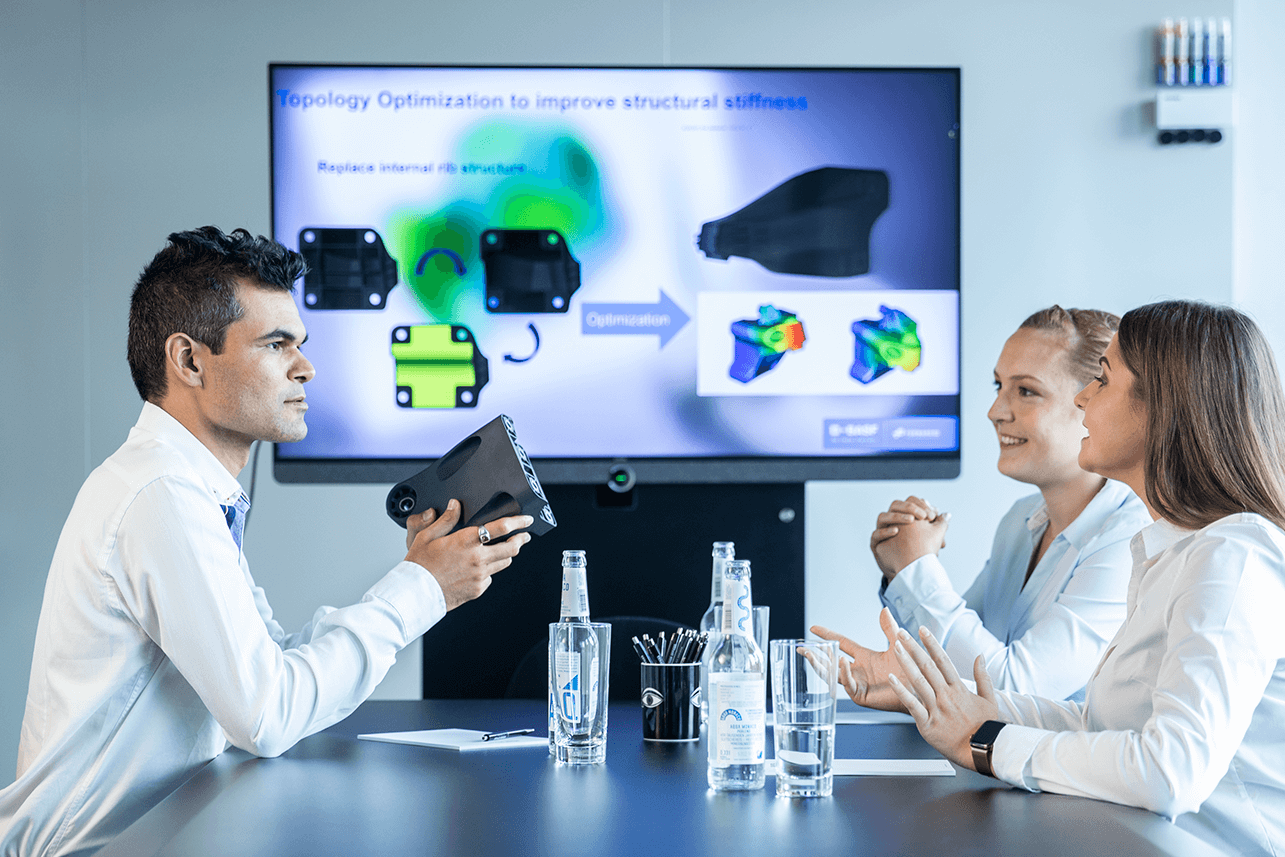

Ultrasim® 3D Simulation (FEA)

We offer 3 different options – from starter to expert:

Discover other Ultrasim® 3D Testing Services

Leverage Our Full-Service AM Excellence

Streamline your 3D printing application development by leveraging our full-service as a one-stop-solution for AM excellence. From material testing to validation and optimization, we’ve got you covered every step of the way.

Ultrasim® 3D Cost Analysis (TCO)

Understand the cost structure of your 3D printed part, what drives costs, and how this compares to other AM technologies.

Ultrasim® 3D Consulting

Discover how simulation of part behavior and Design for AM increases the success rate of your 3D printed part.

Ultrasim® 3D Lattice Design

Compliant lattice structures open exciting product design possibilities that would be previously considered ‘unmakeable. Benefit from better aeration, weight reduction, and increased comfort.

Frequently Asked Questions about Ultrasim® 3D TfAM

Next Steps

Quality Assurance: Material testing ensures the quality, reliability, and performance of 3D printed parts. It helps to validate material properties, assess structural integrity, and determine if the parts meet industry standards, specifications and regulatory requirements. This is particularly important in sectors such as aerospace, automotive, and medical, where strict standards must be adhered to for safety and reliability.

Reliability: Materials can be proofed in different environments and under various conditions e.g. usage near the car engine. This helps to ensure that the 3D printed parts will perform properly in the required application and under environmental influences.

Optimization of Production Processes: Material testing helps optimize production processes to maximize the efficiency and reliability of 3D printing. By understanding material behavior and performance characteristics, manufacturers can fine-tune their printing processes to achieve higher-quality parts with reduced production time and costs.

Risk Reduction: Material testing minimizes the risk of defects or failures in 3D-printed components. By identifying potential issues early in the development process, manufacturers can implement preventive measures to mitigate risks and ensure the integrity of the final product.

Our material testing service covers a wide range of materials used in additive manufacturing, including polymers, metals, ceramics, coatings and composites.

We have focused exclusively on additively manufactured samples or end products. This specialization ensures unparalleled expertise and customized solutions for the unique challenges of 3D printing.

Material testing services typically follow relevant industry standards such as ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and specific standards for additive manufacturing processes and materials.

Yes, material testing services often offer customized testing solutions tailored to the specific needs of clients, including unique material formulations, unconventional geometries, or specialized performance criteria.

Material testing evaluates various parameters such as mechanical properties (e.g., tensile strength, hardness, elasticity), thermal properties, chemical properties, durability and passing or failing.

Yes, we provide a full test report with all needed information and raw datas where technically possible.

The cost of material testing depends on factors such as the type and number of tests required, sample size, complexity of analysis, and turnaround time. Standard tests as e.g. mechanical & thermal tests will be charged as price per sample, industry-specific tests will be charged as total price and parts testing is upon request.

The amount of samples deepens on requirements in the standard and specific requirements of the project/customer. For standard tests as e.g. mechanical & thermal tests are minimum required samples, choose the minimum or an higher amount you need. Industry specific tests has fixed required sample amounts, for each material the same amount is needed. Parts testing samples are custom and need to be discussed with the customer.

The duration of material testing varies depending on the complexity of the tests required, the type of material, if a pretreatment is requested or necessary and the specific requirements of the project. It can range from a few days to several weeks.

No, after 3 or 12 months the order is closed, and a new purchase order is necessary.

Get in touch

Do you have questions about our Testing for AM or other services? Get in touch!

Haven't found what you were looking for?

Take a look at the other products from this portfolio.