Speed alone solves only part of the equation

No need to compromise on quality anymore

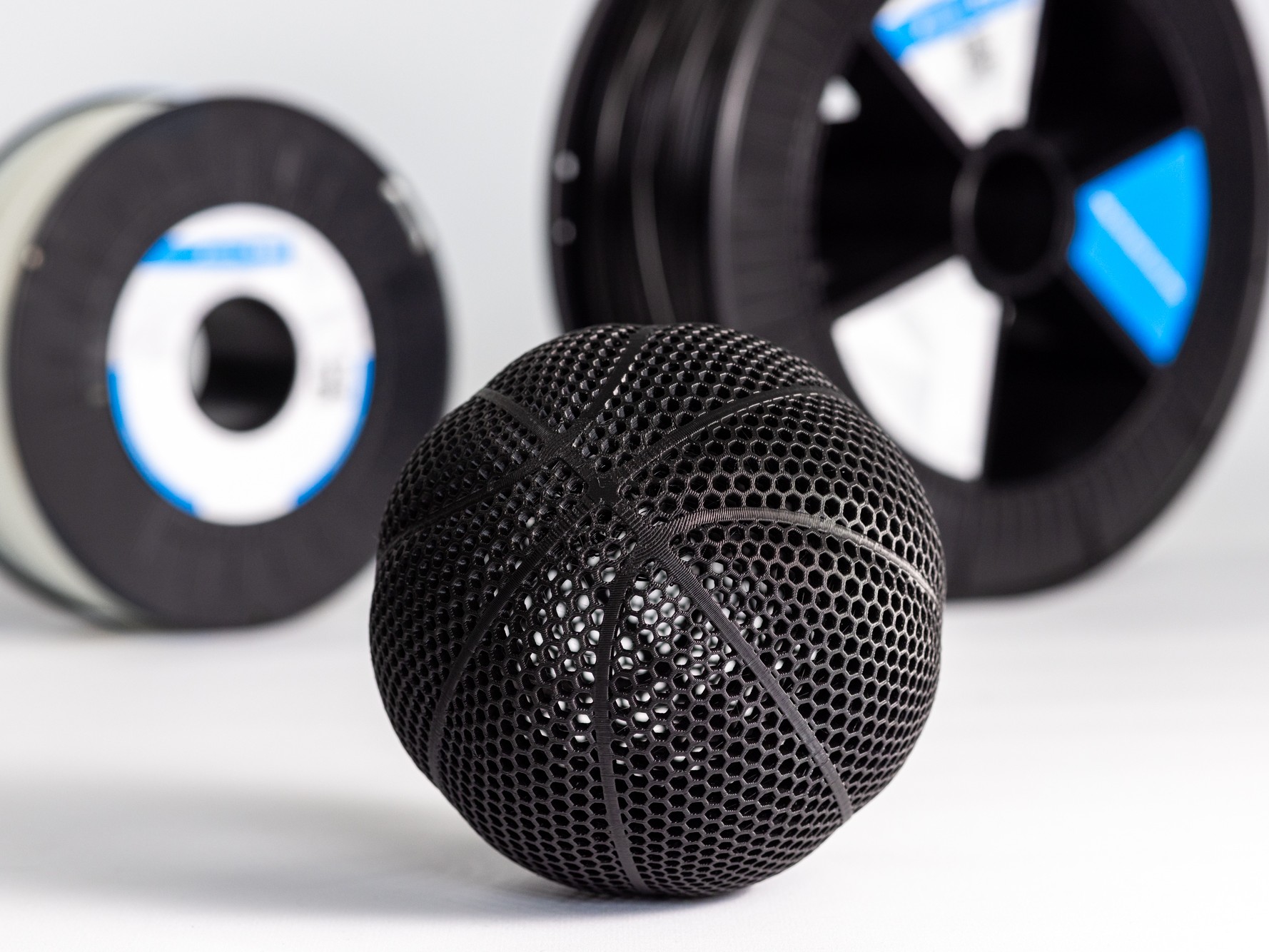

Unlock the full potential of your 3D printing operations and take your business to new heights. Our High-Speed (HS) solutions covers validated materials, along with design and process optimization to get your 3D Printed application into your hands more quickly than ever.

Find out everything you need to know about our high-speed solutions and discover how we can help you achieve your 3D printing goals.

A Full FFF High-Speed Solution

To achieve a full high speed printing experience there’s a need to cover these key elements

High-Speed

Design Optimization

When printing your application, the design should be fully supported for printing in High-Speed. Our team of experts can make this happen.

- Support by our Application Technology Center

- Support by our Solutions department

High-Speed

Validated Materials

After a High-Speed design is ready, you need to select the right Ultrafuse® High Speed Filament and Support Material for your application.

- Ultrafuse® High-Speed Filaments

- Xioneer VXL90 Support Material

High-Speed

Process Optimization

Ensuring the AM technology is able to process the material and design in High-Speed, plus equipment to post process fast

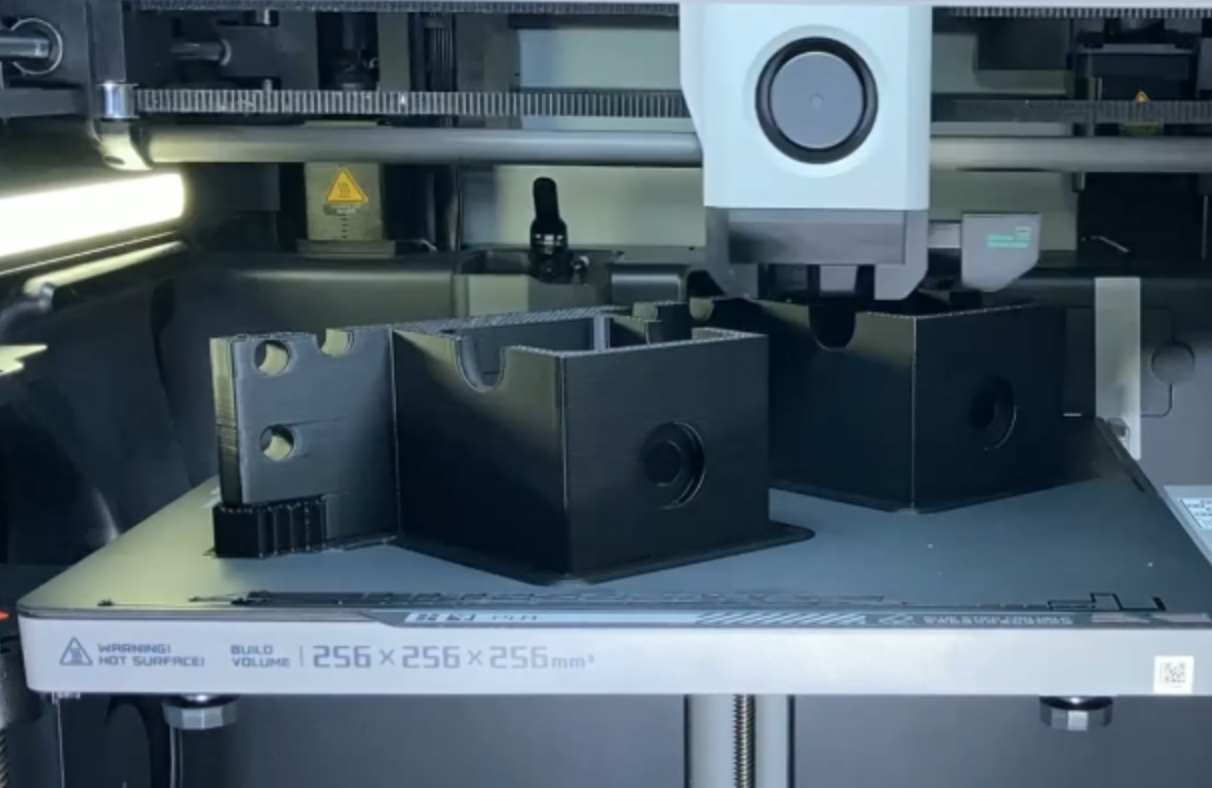

- HS Compatible 3D Printer

- Ultrafuse® HS Print Profiles

- HS Support Removal Station

Ultrafuse® FilamentsHigh-Speed Print Profiles

You will find all of our High-Speed print profiles for validated materials here. Meaning all of the time and effort placed into creating these profiles has resulted in a wide array of High-Speed capabilities now available at your fingertips.

On top of that, you can find potential Print Profiles available within the respective slicers.

First, what is our definition of High-Speed? With the current technologies available today, we’ve validated a new standard. When having a volumetric throughput of at least >8 mm3/sec it’s validated as *High-Speed printing. (> 100mm per second, 0.2mm layer height and 0.4 mm nozzle)

Bambu Lab

Forward AM provides print profiles for following Bambu Lab 3D printers X1 Series, P1S, and P1P.

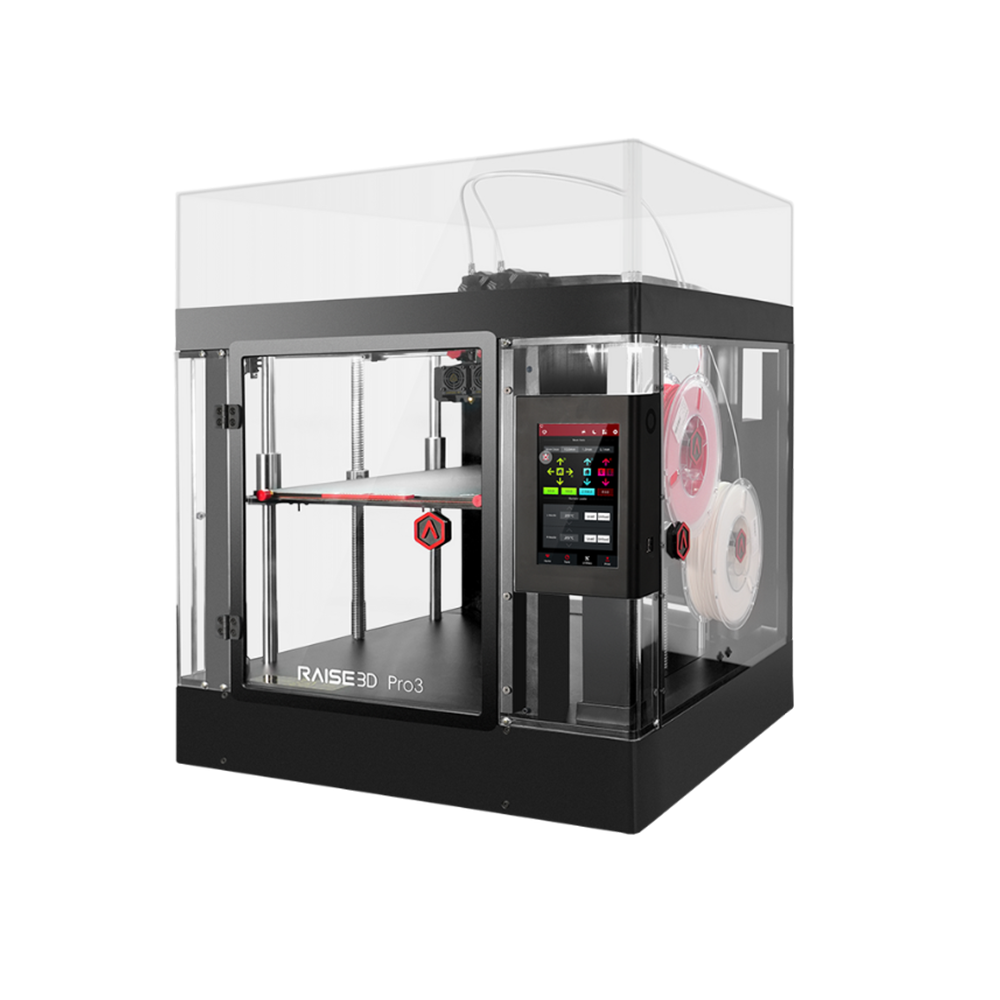

Raise3D

Forward AM provides print profiles for Raise3D Pro3 Hyper Speed printers.

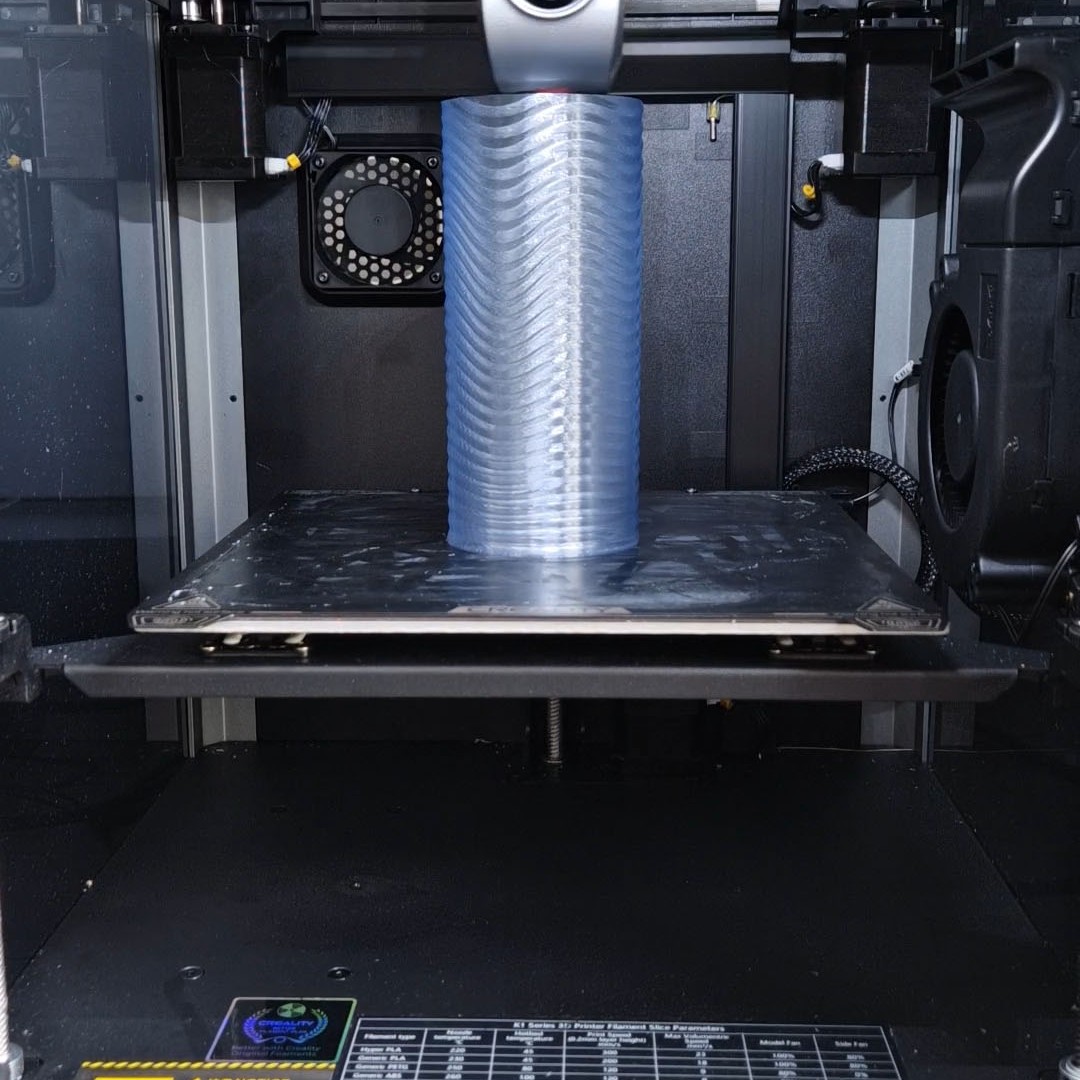

High-Speed Printing Ultrafuse® rPET with Rhubarb by Atelier DARN

Championing Sustainability with Ultrafuse® rPET at FAV 2024. Atelier DARN’s installation, RHUBARB, triumphed at the 2024 Festival des Architectures Vives (FAV) by winning the public prize. This innovative piece, featuring 1,000 3D-printed elements made from Forward AM’s Ultrafuse rPET filament, brilliantly combines art, architecture, and sustainability.

“We had been printing at different speeds since April to complete thousands of elements in a short space of time using a high-speed 3D printer. Actually, we had some doubts before starting the process. But during the process with the material, we have seen that everything goes smoothly: both with individual elements and with experiments where we printed 9 elements at once, which took five to six hours to build at high speed. Actually, there were no problems during the process and we were very happy with the results, how precise the material was.”

ꟷ Peker Ayan, Atelier Darn

More To Know

High-Speed Solutions for Filaments

Innovative Materials and Cutting-Edge Technologies for High-Speed 3D Printing are the Future of Additive Manufacturing

With Forward AM, there is no need to compromise on quality anymore with our High-Speed Solutions. We know that speed alone solves only part of the equation. Our team of experts can help you unlock the full potential of your 3D printing operations and take your business to new heights. Our innovative solutions cover validated materials along with design and process optimization to get your 3D Printed application into your hands in a timely and cost-efficient manner.

NEW HIGH-SPEED FILAMENT

Meet Ultrafuse® PLA Tough

Within this webinar we start with explaining everything about our full HS solution. We also give a definition of our HS standards. After that you will find everything you need to know about our newest member to the material portfolio, Ultrafuse® PLA Tough

Xioneer support material

A perfect fit, discover Xioneer support material

Forward AM and Xioneer join forces to revolutionize 3D printing. Combining Forward AM's trusted Ultrafuse® filaments with Xioneer's VXL supports, this breakthrough enables printing speeds of 100-300 mm/s, slashing production times for high-volume applications.

And for a seamless workflow and having a full HS solution, Xioneer also offers the Vortex EZ Support Material Removal station, ensuring fast and efficient post-processing for flawless results.

Get ready to experience the future of faster, more efficient 3D printing!

Frequently Asked Questions

With nowadays equipment we’ve validated a new standard. When having a volumetric throughput of at least >8 mm3/sec it’s validated as *High-Speed printing. (> 100mm per second, 0.2mm layer hight and 0.4 mm nozzle)

To achieve faster printing speeds, it may be necessary to raise the nozzle temperature. The highest speed mentioned has been determined through our latest tests, ensuring optimal surface quality with a 0.4mm nozzle and 0.2mm layer height. Please note that as printing technology and equipment evolve, we anticipate the possibility of achieving even faster speeds in the future.

*Disclaimer; The product data is provided in good faith and represents typical properties based on our current knowledge and experience; these data are not to be construed as specification limits or mini- mum values. Product properties may be changed without notice. This document does not create any liability, warranty or guarantee of product performance. It is the buyer’s responsibility to determine the suitability of Ultrafuse® products for the intended application

All of our Ultrafuse® Filaments are available via our network of Distributors and Resellers.

Here you’ll find a complete A How-To Guide for Printing Profile Installations on Bambu Lab printers

BASF Forward AM provides print profiles for following Bambu Lab 3D printers:

• X1 Series

• P1S

• P1P

Please be aware that not all Ultrafuse® materials are certified for all Bambu Lab 3D printers due to hardware limitations of the machines (especially a closed chamber for warp sensitive Ultrafuse® materials).

Open the profile

- Download the Ultrafuse® material profile of your choice

- Unzip the file, the file contains the following items:

- A material profile: Ultrafuse XXX.sjon

- Two setting profiles (fiber reinforced materials will have only 0.6mm nozzle profiles):

- BASF 0.20mm Standard Quality – 0.4 nozzle.json

- BASF 0.30mm Standard Quality – 0.6 nozzle.json

- Make sure Bambu Studio is installed on your PC, and the printer you want to use is set-up in the slicer

- Open Bambu Studio

Import material and Settings profiles.

- In Bambu Studio select File>import>import configs…

- Select from the downloaded folder the material config file ‘ Ultrafuse XXX.json’ and both process config files ‘ BASF 0.20mm Standard Quality – 0.4 nozzle.json and BASF 0.30mm Standard Quality – 0.6 nozzle.json’

- A confirmation should pop-up that the configs have been added

- The material can now be selected from the ‘Filament’ dropdown menu

- A provided settings profile can be selected from the ‘Process’ dropdown menu

Remark:We provide usual material settings for a 0.4mm nozzle diameter with a layer height of 0.20mm and a 0.6mm nozzle diameter with a layer height of 0.30mm. You will find in Bambu Studio several other print settings options, created by Babu Lab for Bambu Lab materials. Several of these print settings might also work for Ultrafuse® filaments but are not validated by Forward AM.

All Bambu Lab qualified Ultrafuse® filaments (700gr, 750gr, and 1kg spools) are compatible with the Bambu Lab AMS, including TPU 64D, only exceptions are Ultrafuse® TPU 85A and TPU 95A.

Happy Printing!

Importing Forward AM Print Profiles into Raise3D IdeaMaker

Version 1.0

Open the profile

- Download the Ultrafuse® material profile of your choice

- Unzip the file, the file contains the following items:

- A filaments profile: Ultrafuse_XXX.filament

- 1 or more settings profiles, (Standard Quality and Fina Quality etc)

- Make sure IdeaMaker is installed on your PC, and the printer you want to use is set-up in the slicer

- Open IdeaMaker

Import Material profile

- In the ‘Start Slicing’ menu, make sure your printer model is selected (if you want to print Hyper Speed, make sure this is enabled in your slicer)

- Select the gear icon behind the extruder you would like to add the material to

- Press ‘Import’ and select the ‘.filament’ file

- Press ‘ok’ and save

Import Settings profile

- Back in the ‘Start Slicing’ menu, select ‘Import’ and choose from ‘Local Disk’

- Import the ‘.bin’ file wherever you may have stored it in your PC

- Select the printer you would like to add the profile to

- Under ‘Import’ to the following filament select the previously imported Ultrafuse® filament profile

- Save the changes and press ok

Happy Printing!

A complete overview of our Ultrafuse Filemants portfolio available print profiles you can find here.

On the website of Xioneer you can buy the VXL 90 support material and Vortex EX Support Removal Station directly.