Daylight Line

Daylight Resins

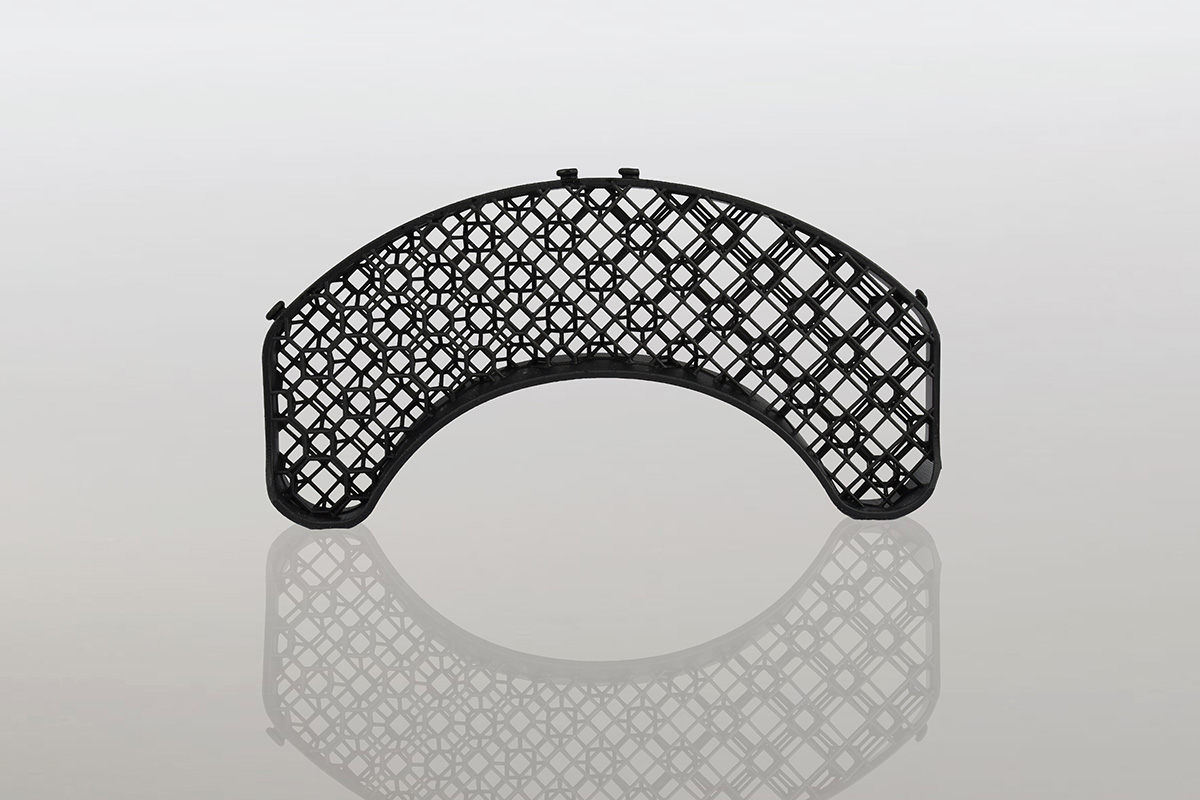

Ultracur3D® EPD Powered by Photocentric is the new Engineering Plastic Daylight (EPD) photopolymer product line. Materials from this line enable economic and large-scale production at a competitive cost. Parts printed with these resins demonstrate high stiffness and flexibility, meeting the needs of customers with demanding applications in 3D printing such as prototyping, engineering and large-scale automotive parts.

Ultracur3D® EPD Product Portfolio

Ultracur3D® EPD 1006

Easy-to-use daylight resin, ideal for prototyping

Benefits at a Glance

- Good toughness and impact resistance

- Easy to print, with nice surface finish and intricate geometries

- Ideal for prototyping, jigs and fixtures

Ultracur3D® EPD 1086

Multi-purpose daylight resin targeting the lowest cost per part

Benefits at a Glance

- Well-balanced mechanical properties

- Cost-effective solution for a wide range of applications

Ultracur3D® EPD 2006

Rigid daylight resin with high stiffness and temperature resistance

Benefits at a Glance

- Very high stiffness and temperature resistance

- Ideal for large-scale objects

- Printed parts exhibit intricate detail

Ultracur3D® EPD 3500

Strong daylight resin with superior strength and stiffness

Benefits at a Glance

- Optimum combination of high strength, high stiffness, and good impact resistance

- Low water uptake

- Ideal for engineering prototypes, also when translucency is required

Ultracur3D® EPD 4006

Durable daylight resin with superior toughness and impact resistance

Benefits at a Glance

- Extremely tough and durable material ideal for functional applications

- Superior impact resistance

- Easy to print and smooth surface finish

BASF Forward AM's and Photocentric's joint mission is to enable cost-efficient, mass-customized production

BASF Forward AM is working in partnership with Photocentric to enable cost-efficient 3D printing technologies for an impressive spectrum of industrial applications and mass-customization. We are currently jointly developing a fully integrated solution that covers the whole spectrum from part design and preparation to finishing of the final parts, leading-edge Additive Manufacturing chemistry from BASF. The innovative materials have been developed to work seamlessly with the unique Photocentric LCD daylight technology, making large volume printing and high-resolution capabilities possible. Our joint goal is to make Additive Manufacturing the solution of choice for the mass-customized serial production of industrial components with great properties at credible prices.

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!