Zortrax Launches New Refined Resin 3D Printing & Post-Processing System

A truly powerful trio has joined the ranks of premier Additive Manufacturing – the Zortrax Inkspire 2 industrial-grade UV LCD 3D printer, the Zortrax Cleaning Station and Zortrax Curing Station, both being professional post-processing devices.

Approved by Top Resin Manufacturers

The Zortrax Inkspire 2 combines utmost precision with high-speed capabilities and is compatible with a wide range of high-grade engineering resins made by top global manufacturers like BASF Forward AM. After completing a thorough and detailed double-validation process, Zortrax guarantees that the prints, manufactured on the Inkspire 2 and post-processed with their Cleaning and Curing stations, will meet all the mechanical and thermal properties declared for each resin in their portfolio.

The Zortrax Cleaning Station and Zortrax Curing Station, like the Inkspire 2, have also been validated by BASF Forward AM. Post-processed sample 3D prints were tested to confirm they achieved compliance with all the properties declared for the applied resin. Moreover, these devices can also operate independently of the Inkspire 2 3D printer with different technologies such as UV LCD, DLP, and SLA.

Innovative Solutions for Prototypes and Final Models

Through this brand-new resin 3D printing & post-processing system, Zortrax provides innovative solutions that cater to the needs of professional users. While resin 3D printing has often been associated with producing prototypes, this cutting-edge system changes all that. With durable engineering resins, such as Ultracur3D® made by BASF Forward AM, users can successfully print both prototypes and final models utilizing the advanced, automated, and versatile Zortrax resin 3D printing & post-processing system.

The technological advances introduced in the Inkspire 2 are a huge step forward by Zortrax and their UV LCD solutions. In comparison to their previous generation 3D printer, the improved refined resin 3D printing system has:

- 7x More Powerful UV Light Engine

- 40% More Uniform UV Light Distribution

- 4x More Build Volume

A Powerful Trio

The Zortrax Inkspire 2

The Inkspire 2 is a high-end, industrial-grade UV LCD 3D printer with 192 x 120 x 280 (mm) workspace. It has been specifically designed to work with quality resins such as Ultracur3D® as well as to offer an easy, automated, and user-friendly operation at the same time. The cutting-edge proprietary light engine, developed entirely in-house by Zortrax, provides the same levels of UV exposure across the entire platform. This results in the user achieving the same print quality, regardless of whether the models are placed in the center or on the edges of the platform.

While Zortrax engineers were developing the Inkspire 2, leading resin manufacturers actively participated in the prototype testing stage. The printing parameters for every supported engineering resin introduced were thoroughly validated to certify that the mechanical and thermal properties achieved in parts fabricated on the Inkspire 2 matched or even exceeded those declared by the manufacturer. Moreover, thanks to the high-power light source implemented in the machine, users can now 3D print with some resins dedicated to DLP technology. In total, there are four resin lines dedicated to the Inkspire 2: Elastomeric Resins, Rigid/Tough Resins, Castable Resins and Basic Resins. The following Ultracur3D® resins are validated and approved:

Although the Inkspire 2 is more advanced than its predecessor, it is even easier to operate. Most processes are automated, making the performance of this machine cleaner and more convenient for the user. A sensor measures the amount of resin needed to 3D print a certain model. If the liquid in the resin vat does not reach the designated level, the 3D printer informs the user of the issue, therefore minimizing delays. The Inkspire 2 also has closed air circulation, including HEPA filters which are installed in the printer to absorb chemical particles during processing. This reduces the unpleasant smell that can be caused by the vapors created during 3D printing.

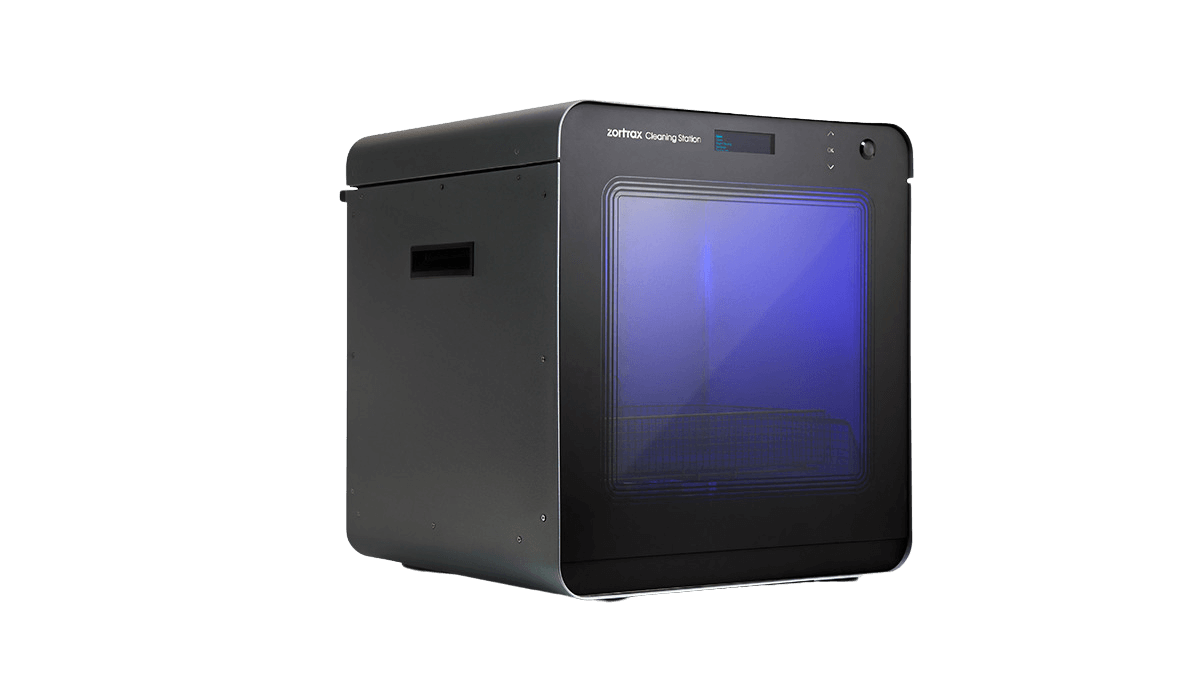

The Zortrax Cleaning Station

The true success of professional 3D prints is not only in using a reliable, cutting-edge 3D printer, but also in utilizing the proper steps after the printing process is completed. The Inkspire 2 is complemented by the automated ecosystem for professional post-processing – the Zortrax Cleaning Station. Its main purpose is to remove excessive resin from the models’ surfaces, as well as from the nooks and crannies. Due to its high-volume tank, this system can clean relatively large models printed on nearly any model of resin 3D printer available on the market. Additionally, with the inclusion of a special filtering system, IPA can be safely reused for multiple cleaning sessions.

The Zortrax Curing Station

The Zortrax Curing Station is an industrial class curing chamber which provides consistent UV exposure and is enhanced by a rotating table that ensures all models are free of any weak spots caused by insufficient UV exposure. This station provides crucial UV curing once resin 3D printing and cleaning have been completed. This important process is necessary to preserve the models’ dimensional accuracy and is vital for most resins to achieve their target mechanical properties.

Zortrax is an established manufacturer of 3D printers for both desktop users and industrial sectors. The products offered by the company operate within four technologies: LPD, LPD Plus, UV LCD and SVS. The brand has built a strong position in the market by offering comprehensive solutions for 3D printing including: printing materials and peripherals as well as dedicated Z-SUITE software and Zortrax inCloud platform for remote management of the printing process and personnel. Zortrax machines are used by thousands of customers around the world in industries ranging from architecture, medicine, education, and design to automotive, engineering, and aerospace. This has enabled the company to build a business which operates on an international scale providing devices that are reliable and precise, adapted to work in harsh environments and meets the most stringent operating standards. While at the same time, they are also intuitive and easy to use. Through extensive partnership efforts, the company manages to create high-quality 3D printers by cooperating with three key industrial sectors: education, medicine and space. Zortrax engineers also developed the technology to print composite models from two PEEK blends in collaboration with the European Space Agency. Zortrax solutions are used by such giants as: NASA, Toyota and Bosch.

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.