No Time to Spare for a Spare Part: Ultrafuse® PLA and FFF to the Rescue

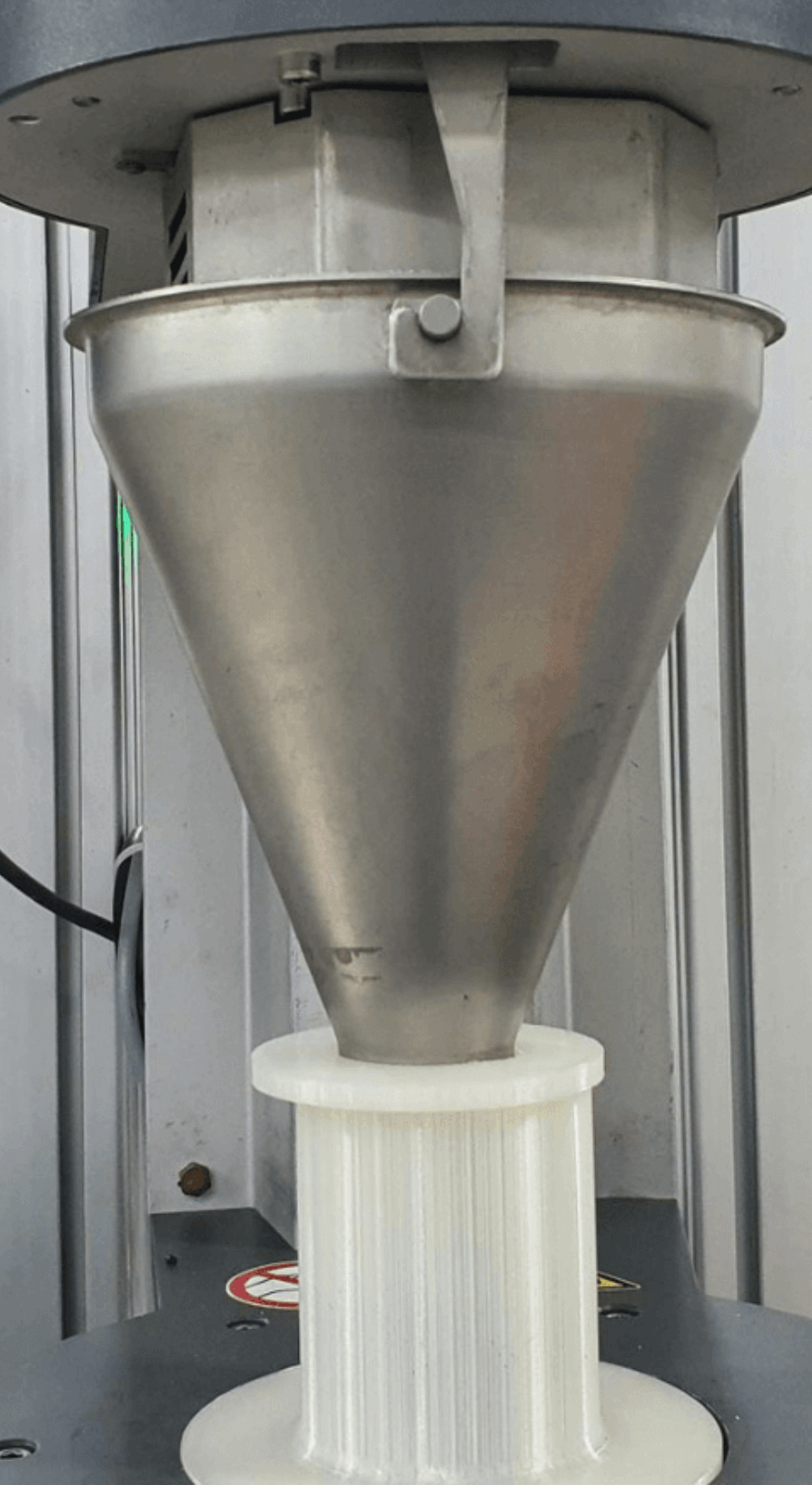

When the original Flow Adapter part of the sidedosing unit on an extruder was nearing its end of life, the team at Forward AM explored the traditional methods of replacing it. Most of these options included long lead times and relatively high costs for one small part of the machine. This challenge compelled our team to begin to rethink the best way to replace this essential part.

The main function of the Flow Adapter part is to act as a guiding piece during the conveyor process, which in turn helps to avoid the spilling of raw material. But it is a critical component needed for the machine to function properly. And as we only required a single part, we welcomed this as the perfect opportunity to utilize our extensive knowledge of materials and our 3D printing expertise to help ourselves to save both time and costs.

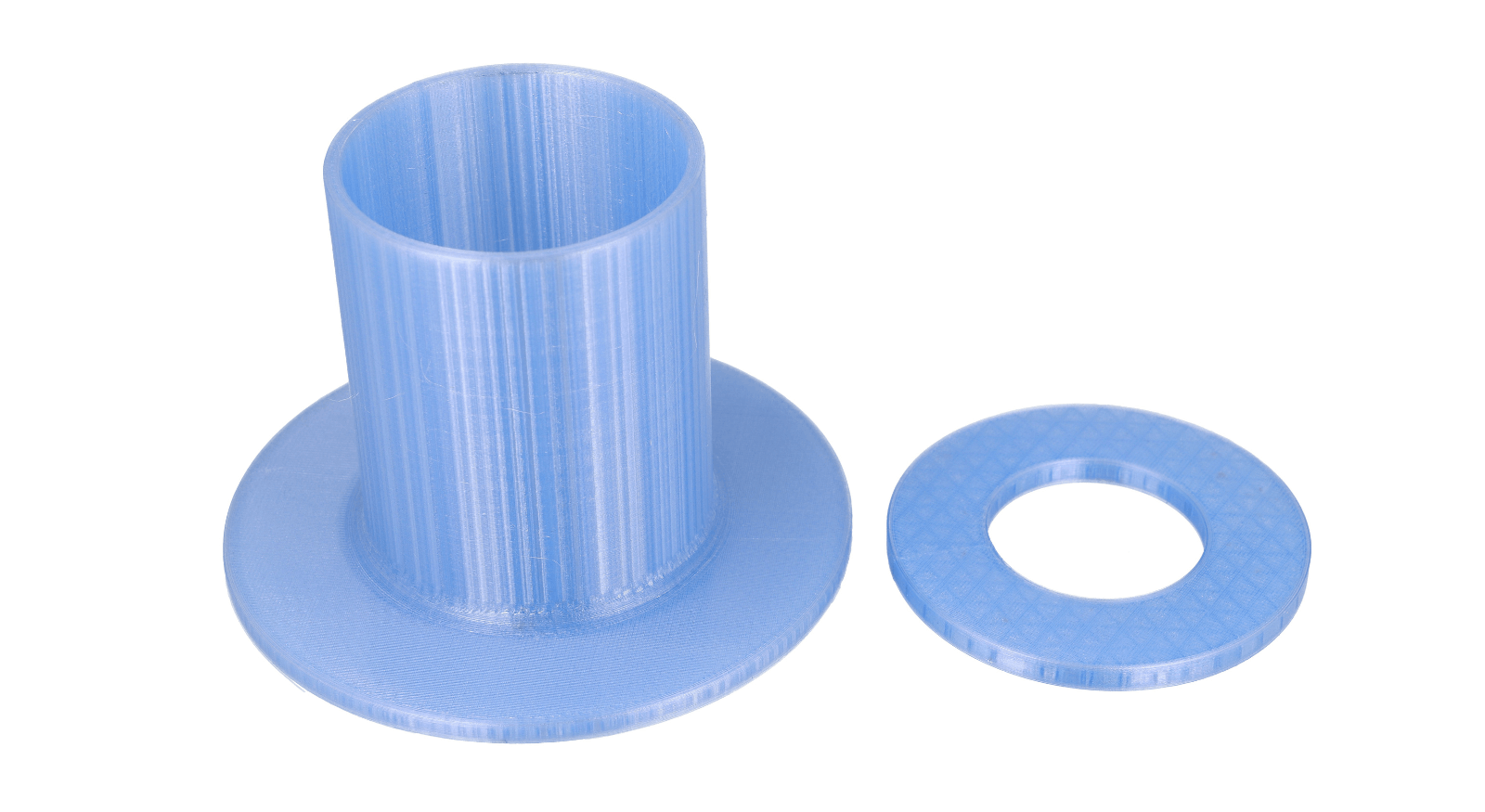

Using Ultrafuse® PLA and FFF printing technology, Forward AM was able to internally print the necessary part in two days, instead of waiting two weeks to receive it from the original supplier. We were also able to save ~120€ and did not experience any production downtime.

PLA is one of the most used materials for 3D printing, available in a wide range of colors and many users appreciate the plant-based origin of this material. When properly cooled, PLA has a high maximum printing speed and sharp printed corners. And with low warping levels of PLA printed parts, it is a popular plastic for home printers, hobbyists, prototyping and for schools.

Two other materials that would have been well suited for this project are Ultrafuse® PP and Ultrafuse® rPET. Ultrafuse® PP is high-performance thermoplastic with low density, high elasticity and high resistance to fatigue. The mechanical properties make it an ideal material for 3D-printing applications which have to endure high stress or strain. With high chemical resistance and a high isolation value, PP is one of the most used materials in the world, due to its versatility and ability to engineer lightweight tough parts.

For those looking for a more sustainable option, Ultrafuse® rPET is a filament made from recycled material that is a serious alternative to filaments made from virgin raw materials. The “r” stands for recycled, as rPET is made from recycled PET post industrial waste. Components printed with Ultrafuse® rPET print, look and perform as outstandingly as our PET filament made from virgin raw material.

These are the kinds of innovative solutions we work to develop and implement each and every day for customers around the globe as the applications for 3D printing are limited only by our imaginations. There is a bright future ahead of us and we are excited to see how Additive Manufacturing will change the industries around us. We not only help ourselves but can assist so many others by collaborating to create innovative solutions as the only way forward is together.

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.