Share this page

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM. Through this collection, we dive into the stories of Digital Manufacturing Pioneers who are reshaping the industry with their innovative 3D printing services. These leaders have not only embraced additive manufacturing as a core element of their business but have also chosen BASF Forward AM as a trusted partner in materials and solutions. Each interview seeks to uncover the motivations, challenges, and triumphs behind their decision to pioneer in the 3D printing space, offering inspiration to others in the field.

Join us as we explore these narratives, layer by layer, to better understand the evolving landscape of digital manufacturing and the visionaries driving its future.

Interview #1: Meet Stijn Paridaens, CEO at Ziggzagg, a 3D Printing Service based in Belgium blending craftsmanship with advanced technology to cater to diverse sectors, including industrial, healthcare, automotive, and consumer products.

Getting to know Stijn Paridaens

Marco: Before we dive deeper, could you share a bit more about your background and what led you to the forefront of the additive manufacturing industry?

Stijn: “My journey into the world of 3D printing was driven by a fascination with technology and its potential to reshape traditional industries. With a background in engineering and a keen eye on future technologies, I saw additive manufacturing as a frontier worth exploring. It was the perfect blend of innovation, creativity, and problem-solving, which led me to start Ziggzagg.”

More about Ziggzagg and its story

Marco: Let’s start from the beginning. How did you find your way into additive manufacturing, and what inspired you to start your own 3D printing service?

Stijn: “Ziggzagg was born in 2010 from a deep-seated passion for pushing the boundaries of what’s possible with technology. The potential of 3D printing to transform manufacturing into a more flexible, efficient, and customizable process was too compelling. We saw an opportunity to not just participate in this revolution but to lead it. What sets us apart is our relentless pursuit of excellence in technology and our unwavering commitment to our customers. We specialize in delivering high-quality, quick-turnaround 3D printing solutions, focusing on sectors like the medical industry, machinery and equipment, and increasingly, defense.”

“The potential of 3D printing to transform manufacturing into a more flexible, efficient, and customizable process was too compelling. We saw an opportunity to not just participate in this revolution but to lead it.”

Ziggzagg journey began 14 years ago, driven by a passion for technology and innovation.

Discovery of BASF Forward AM

Marco: Your partnership with BASF Forward AM has been pivotal. Can you expand on how this collaboration began and its evolution?

Stijn: “Our partnership with HP 3D Printing led us to BASF Forward AM. We were searching for top-notch materials that could elevate our offerings. BASF Forward AM stood out for their quality and extensive materials portfolio. We were looking for partners, not suppliers, and that’s exactly what we found in 2021, marking the start of a close and important collaboration aimed at developing groundbreaking solutions for our clients. That year, we made the strategic decision to introduce BASF Forward AM’s Ultrasint® TPU01 to our portfolio for our MJF 3D Printers. This was a significant shift from our previous use of other TPUs, driven by our belief in Ultrasint® TPU01’s superior performance, durability, and cost-efficiency.

The transition involved rigorous testing and optimization, undertaken in tandem with BASF Forward AM to meet our stringent quality and performance benchmarks. The advantages of switching to BASF Forward AM’s Ultrasint® TPU were immediately clear: easier printing processes, exceptional support, and versatile post-processing capabilities, all of which significantly enhanced our product offerings. Our commitment to excellence is recognized through our ISO 9001 and ISO 14001 certifications, further solidifying the trust our customers place in Ziggzagg and our chosen materials.”

Deep Dive into BASF Forward AM Ultrasint® TPU

Marco: Let’s talk about TPU. How has it benefited your operations?

Stijn: “TPU from BASF Forward AM has revolutionized our operations. Its flexibility and durability have allowed us to break into new markets, creating products that surpass our clients’ expectations. It’s been a real game-changer, especially with the warm unpacking process speeding things up.“

Warm Unpacking is now Faster Unpacking leading to Production Efficiency.

Marco: What has been your experience integrating a “different” unpacking into your production?

Stijn: “It’s true that with other TPUs we had a wider-open window for unpacking, on the other hand, integrating the warm unpacking process for Ultrasint® TPU01 into our production line has streamlined our processes, significantly reducing cooling times and improving the overall quality of our printed products. We see it as a benefit in our offering since it gives us the ability to provide ‘next day’ services, effectively making it a faster unpacking process. It’s true that it requires precise timing and perfect workflows, but that’s what we do. Moreover, BASF Forward AM doesn’t just provide exceptional know-how documentation; their service is great as well, offering personalized support and expertise that greatly improve our operational efficiency and output quality.”

“We see warm unpacking as a benefit in our offering since it gives us the ability to provide ‘next day’ services, effectively making it a faster unpacking process.”

Ziggzagg partnered up with Bahr Innovations to revolutionize the production of Supra-Malleolar Orthosis (SMOs).

Deep Dive Application Example: Supra-Malleolar Orthosis (SMO)

Marco: Can you tell us a bit more about your case study with Bahr Innovations?

Stijn: “We partnered with Bahr Innovations to revolutionize the production of SMOs using Ultrasint® TPU01. This collaboration has enabled the creation of custom-fit, more comfortable, and efficient SMOs, showcasing the power of additive manufacturing in the medical field.”

Application Spotlight: 3D Printed Orthosis

Bahr Innovations leverages additive manufacturing to revolutionize the production of Supra-Malleolar Orthosis (SMO), employing Ultrasint® TPU01 and HP Multi Jet Fusion technology. This approach overcomes traditional manufacturing challenges, offering custom-fit, functional SMOs that significantly enhance patient comfort and support for various foot and ankle conditions.

Benefits

- Customization: Tailored designs ensure perfect anatomical fit, improving support and comfort.

- Lightweight Design: Complex geometries enable strong yet lightweight SMOs, improving wearability.

- Speed of Production: Reduces fabrication time from weeks to hours, delivering orthotics faster.

- Improved Quality and Comfort: Superior fit and flexibility from digital design and 3D printing.

- Cost Efficiency and Increased Capacity: 50% cost reduction and 3x production capacity increase.

- Enhanced Product Life: Advanced materials and post-processing for better aesthetics, comfort, and durability.

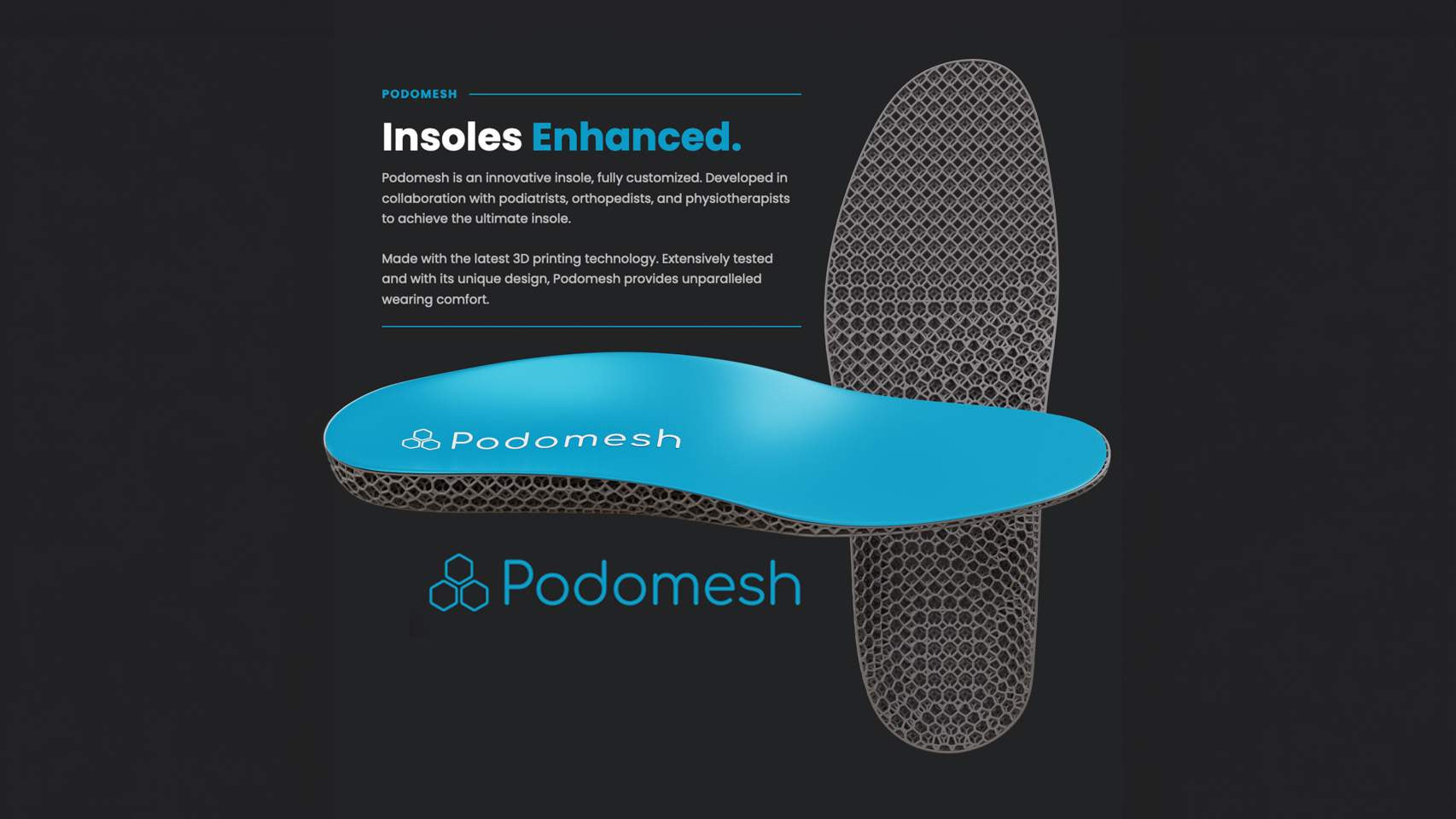

In collaboration with BASF Forward AM, Ziggzagg has developed a full end-to-end solution that leverages 3D printing for custom-fit, functional footwear: Podomesh.

Exploration of other Services & Solutions by Forward AM

Marco: Could you share your experiences with specialized services like Lattice Design?

Stijn: “Our Lattice Design service has been a boon, particularly for the aerospace and automotive sectors, allowing us to create structures that are both lightweight and strong, improving material efficiency and customer satisfaction.”

Full End-to-End Solutions: Podomesh

Marco: What is Podomesh?

Stijn: “Podomesh reflects our dedication to innovation and improving patient outcomes. This project, in collaboration with BASF Forward AM, showcases our ability to provide custom-fit, functional footwear through a comprehensive end-to-end solution, marking a significant quality leap from FDM to MJF printing technologies.”

Grand Finale: The Unusual and the Unique

Marco: What’s the strangest or most unusual request you’ve ever received for a 3D printing job?

Stijn: “We’ve seen a fair share of unique requests, but a standout has to be the life-size statue of chocolatier Pierre Marcolini for his London store, completely gold plated. It was an old project, but it remains one of the most memorable.”